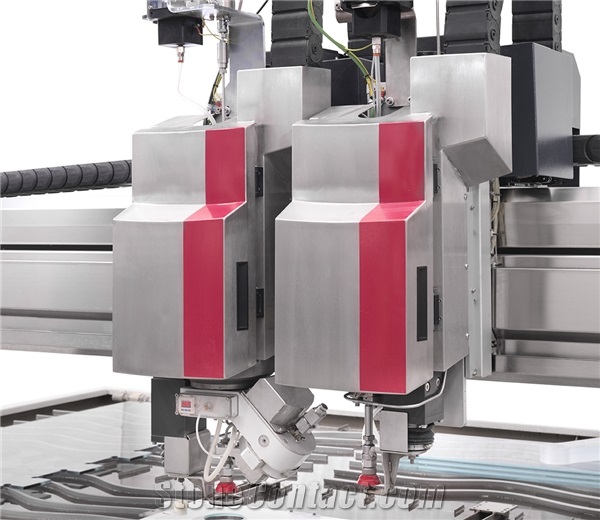

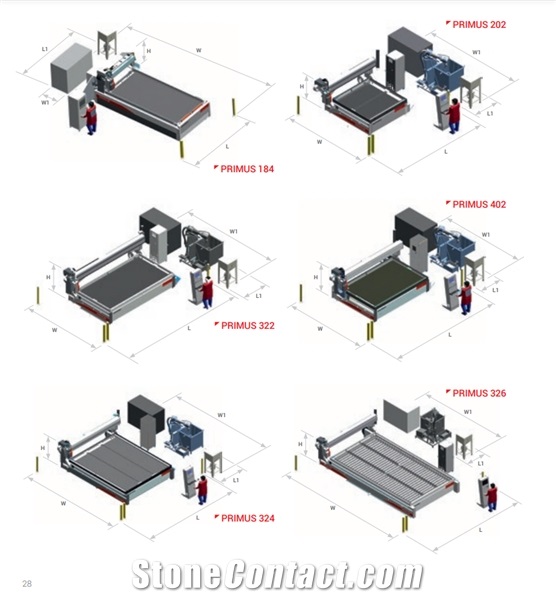

PRIMUS SERIES Waterjet cutting machines

FOB Price:

Parameters |

Unit |

PRIMUS 184 |

PRIMUS 202 |

PRIMUS 322 |

PRIMUS 402 |

PRIMUS 324 |

PRIMUS 326 |

Max. capacity of the piece support table |

kg/sq.m |

1000 |

1000 |

1000 |

1000 |

1000 |

1000 |

A-axis rotation |

° |

+/-60° |

+/-60° |

+/-60° |

+/-60° |

+/-60° |

+/-60° |

W1 width |

mm |

800 |

4940 |

4940 |

4940 |

4940 |

4940 |

L1 length |

mm |

3900 |

1650 |

1650 |

1650 |

1650 |

1650 |

Machine width (W) |

mm |

6490 |

4940 |

4940 |

4940 |

7130 |

9210 |

Min. centre distance between cutting heads (3 axes) |

mm |

- |

280 |

280 |

280 |

280 |

280 |

Waterjet max pressure |

Mpa |

420 |

420 |

420 |

420 |

420 |

420 |

C-axis (opt.) |

° |

Endless |

Endless |

Endless |

Endless |

Endless |

Endless |

Waterjet pump power |

kw |

22 |

22 |

30 |

37 |

45 |

75 |

Z-axes travel |

mm |

250 (200 with 5-axis head) |

250 (200 with 5-axis head) |

250 (200 with 5-axis head) |

250 (200 with 5-axis head) |

250 (200 with 5-axis head) |

250 (200 with 5-axis head) |

Max. sheet dimensions for loading X-Y (mm) |

mm |

2010x4100 |

2080x2250 |

3300x2250 |

4100x2250 |

3300x4300 |

3300x6300 |

Min. centre distance between cutting heads (5 axes) |

mm |

- |

500 |

500 |

500 |

500 |

500 |

Waterjet pump capacity |

L/min |

2 |

2 |

3.2 |

3.8 |

4.1 |

7.8 |

Min. centre distance between cutting heads (3 + 5 axes) |

mm |

- |

340 |

340 |

340 |

340 |

340 |

Machine length (L) |

mm |

3900 |

5070 |

6280 |

7590 |

6280 |

6280 |

Machine height (H) |

mm |

3000 |

5000 |

5000 |

5000 |

3000 |

3000 |

Dimensions of the work table |

mm |

1860x4000 1700x3800* |

2000x2000 |

3210x2000 |

4000x2000 |

3210x4000 |

3210x6000 |

X - Y axis displacement speed |

m/min |

45 |

45 |

45 |

45 |

45 |

45 |

H max (optional) |

mm |

- |

3000 |

3000 |

3000 |

- |

- |

WITH OVER 6,500 PACKAGES INSTALLED AND USED BY SATISFIED CUSTOMERS IN 180 COUNTRIES THROUGHOUT THE WORLD, ICAM IS A HIGHLY RELIABLE

AND ROBUST SOFTWARE THAT COMBINES TOP PERFORMANCE WITH EXTREMELY EASY USE.

User-friendly

A simple, powerful interface for working quickly and easily.

Time saving

Positioning of stops and suction cups within the CAD/CAM environment, minimising tooling times even with project modifications.

Innovative

A unified interface for the CAD and CAM environments.

Automated

The parametric library and Indoor module allow machining operations to be generated quickly and automatically on the basis of the item being created.

Service quality

Worldwide Service with a high level of expertise

No Reviews

Related Products:

Intermac Glass & Stone Division - Biesse Spa

Sales Manager

Italy

Italy

Tel:+39 721 483100

Contact supplier

Angelo Busetti

Angelo Busetti