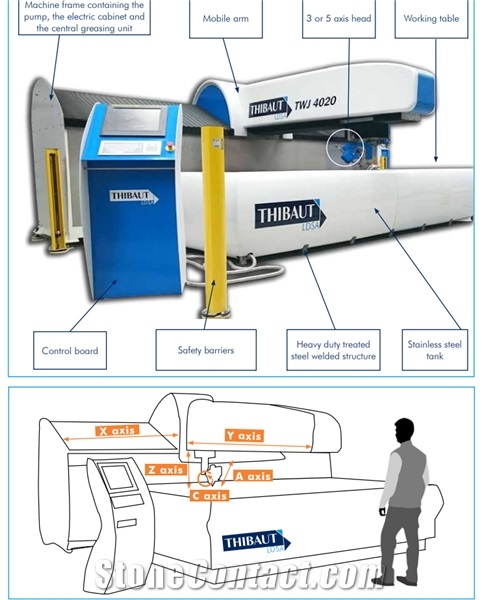

TWJ 4020 TWJ 3317 Waterjet Cutting Machine 3 Or 5 Axis

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

Usage:

Granite, Marble, Limestone, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Remote troubleshooting, Field troubleshooting

Machinery Function Features

HIGH PRECISION HIGH PRESSURE WATERJET

The cutting system is a high pressure water jet up to 4150 Bar/ 60 000 PSI (optional : 6000 Bar / 87 000 PSI ) generated by an intensifying pump. This high pressure water is concentrated into a fine but very powerful water jet after going through an orifice.

In a mixing chamber just after the orifice, abrasives are added to the jet which reach a speed of 900 m/s almost MACH 2. It then goes in a focalization tube to be projected onto the work-piece. The result is an abrasive jet of less than one millimeter diameter capable of cutting the hardest materials.

WORKING TABLE OF LARGE DIMENSION

A large working table enabling to cut the pieces of dimension 4000×2000 mm (TWJ4020).

Thanks to the mobile machine arm, access to the table is eased. The operation can lay the slabs from all the table sides.

The working table is composed of galvanized vertical blades (S shape), stainless steel frame and grates on tank bottom for recovering of waste material which might have fallen.

Water level variation by Ballast system (quick and ecological). By raising slightly the water level above the slab one can cut with the same efficiency yet reducing drastically the sound level.

AUTOMATIC SYSTEM CONTROLLED BY NC

The NC controls the head movement following the program written into the NC or on PC.

The T’CUT software is identical to the software of the THIBAUT NC sawing machines.

Work-pieces are positioned on the working table. The table is in a stainless steel tank full of water.

Most of the materials do not require any clamping. The water in the tank absorbs the jet residual energy. The working table as well as the abrasive suction pipes positioned in the tank bottom (only with option abrasive muds evacuation) can be damaged or worn out by the jet if left idle a certain using time but can be replaced easily.

VERY HIGH PRESSURE PUMP

The VHP pump is integrated in the machine frame (back side) for a space optimization. It is entirely controlled by the NC. The pressure is variable from 500 to 4150 bar / 7250 to 60000 PSI via IHM (option 6000 bar / 87 000 PSI).

This enables to drill with low pressure to avoid any splash or material breakage when jet is opened in full material. Then, the NC controls high pressure automatically.

Technical Data

Parameters |

Unit |

TWJ 4020 |

TWJ 3317 |

Z-axes travel |

mm |

200 |

200 |

Cutting precision |

mm |

+/- 0,1 (with a constant room temperature 15 Celsius) |

+/- 0,1 (with a constant room temperature 15 Celsius) |

Waterjet pump power |

kw |

37 |

37 |

Dimensions of the work table |

mm |

4050x2050 |

3350x1750 |

Machine deviation |

mm |

+ 0,05mm on 500mm |

+ 0,05mm on 500mm |

Machine height (H) |

mm |

2400 |

2400 |

Machine width (W) |

mm |

4500 |

4200 |

A axis (tilting of the cutting head) |

° |

+/- 45° in cut (possible +/- 60° maximum) |

+/- 45° in cut (possible +/- 60° maximum) |

X - Y axis displacement speed |

m/min |

0-10 |

0-10 |

Y-axes travel |

mm |

2050 |

1750 |

Approximate weight(including table) |

Kg |

6 300 (with tank without water) |

4410 (with tank without water) / without the pump of 1100 kg |

Repeating operation |

mm |

less than + 0,02 |

less than + 0,02 |

Waterjet max pressure |

bar |

6 |

6 |

Machine length (L) |

mm |

6520 |

5865 |

C axis (rotation around vertical axis) |

° |

+/- 370° |

+/- 370° |

X-axis travel |

mm |

4050 |

3350 |

Installed Power |

kW |

45 |

45 |

Capacity of external tank for abrasive |

Kg |

400 |

400 |

Voltage |

V-Hz |

3 x 400 V - 50 Hz |

3 x 400 V - 50 Hz |

Working Thickness |

mm |

1 to 200 |

1 to 200 |

Software

T’Cut : 2D 1/2 cutting software

Installed on a computer or on the machine:A Software fully developed by THIBAUT.

• Take pictures of your slabs to detect and mark the defaults

• Do some vein matching to present your customer a unique realization before

• Create parametric shape or drawing

Reviews

No Reviews

Related Products:

Waterjet Machines

Machinery

Stone Factory Machines

Stone Finishing, Profiling Machines

Granite Waterjet Machines

Marble Waterjet Machines

Limestone Waterjet Machines

Onyx Waterjet Machines

Artificial Stone Waterjet Machines

Basalt Waterjet Machines

Quartzite Waterjet Machines

Sandstone Waterjet Machines

Travertine Waterjet Machines

Thibaut Machines

TWJ 4020 TWJ 3317 Waterjet Cutting Machine 3 Or 5 Axis

Mr.Baptiste Lebouteiller

Sales Manager

France

France

Tel:+33-2 31 66 68 00

Contact supplier

Baptiste Lebouteiller

Baptiste Lebouteiller