Curbstone Stone Cutting Machine Line DFLSX1200-13S

FOB Price:$52000-54000

Type:

Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

Usage:

Granite, Marble, Limestone, Slate, Sandstone

After-Sale

Lead Time:

7 days after receiving deposit

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Port:

Xiamen Port- China

Delivery Details: FOB,CFR,CIF,EXW

Payment :

More

Machinery Function Features

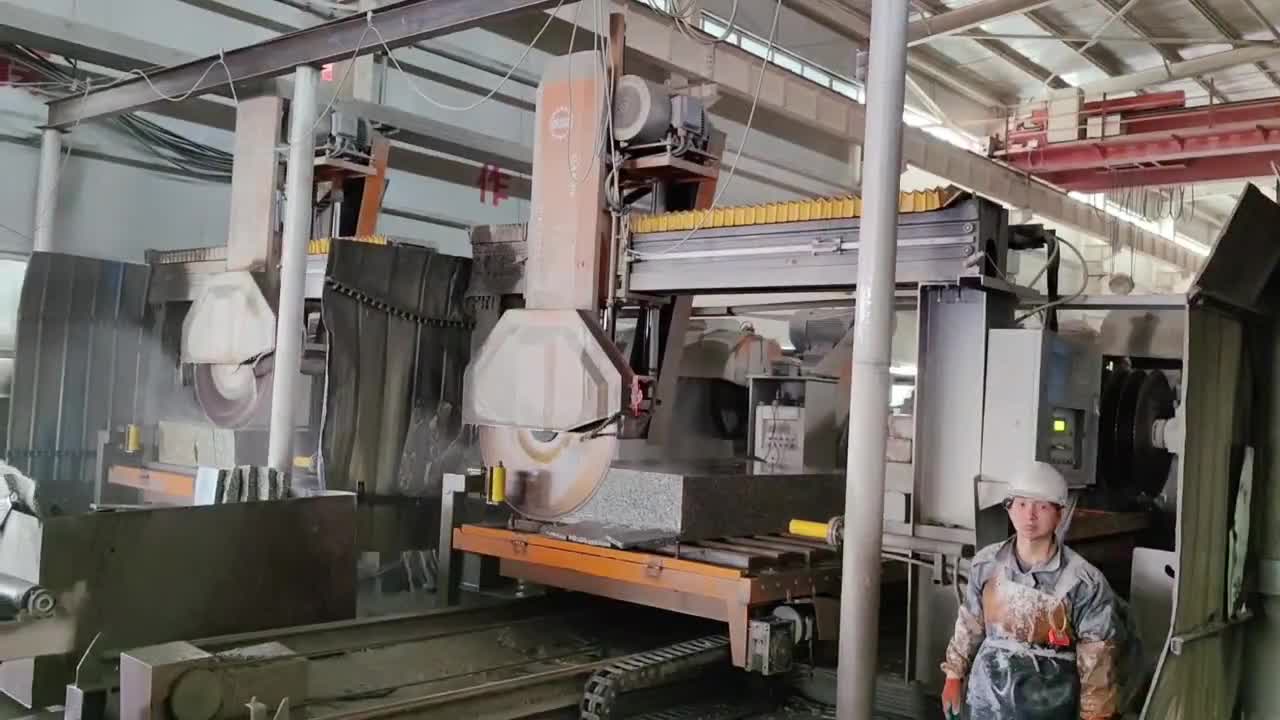

Introduction of Kerbstone Cutting Machine

Curb cutters are powerful and efficient tools used in the construction industry to cut and shape curbs, also known as Curb, for paving roads, sidewalks and other outdoor areas. These machines come in different models and sizes, from handheld models to large industrial machines for heavy-duty cutting.

The use of curb cutters has revolutionized the curb cutting process as it allows for precise and accurate cuts with a better finish compared to traditional methods. Designed to cut hard materials such as granite, concrete and asphalt, they are ideal for use in construction projects of all sizes.

The use of curb cutters is becoming increasingly popular among contractors and construction companies as the demand for quality, durable paving materials continues to grow. They are durable, easy to operate and cost-effective, making them a must-have tool for anyone in the construction industry.

In short, curb cutters are an essential tool for cutting and shaping curbs used in the construction industry. They are versatile, efficient and allow for precise cutting to provide a high quality finish for paving projects.

The advantage of Kerbstone Cutting Line

1. Save cutter head: the machine uses multiple knives to cut at the same time, each time down about 3-5mm (depending on the stone and cutter head), saving the consumption of cutter head.

2. Labor saving: only one worker is needed to watch the whole production line, the machine adopts roller to transfer the stone and induction to stop and run automatically.

3. Save plant space: compared with other cutting methods, the machine only needs 12*5m space to produce the same capacity.

The Feature of Curb Stone Cutting Machine

1. The size of the trolley is enlarged, and two sheets can be placed at one time, which greatly improves the work efficiency;

2. The diameter of the main shaft is 120mm, after heat treatment and other processing technology, it can hang 12 pieces of 1.2m steel saw blades at a time;

3. The whole machine has an integrated structure, no need to lay a foundation, and it is easy to install.

Technical Data

Parameters |

Unit |

DFLSX1200-13S |

Max.blade diameter |

mm |

12000 |

Worktable size |

mm |

2000*2500 |

Max.vertical stroke |

mm |

450 |

number of blades |

pieces |

10-12 |

Max.vertical stoke |

mm |

600 |

machine weight |

t |

10 |

Weight |

t |

25 |

machine size |

mm |

24000*5000*4500 |

Voltage |

Volt |

380 |

blade diameter |

mm |

1200 |

electricity condition |

v |

380 |

Max.number of blades |

pcs |

13 |

Video

Install Video

Operation Video

Screen.PrimaryScreen.Bounds.Height

Recommended Infrared Bridge Cutting Machine Products

Reviews

5 / 5 Very satisfied

t

Ami***

3/12/2025 12:21:42 PM

Related Products:

Infrared Bridge Cutting Machine

Machinery

Stone Factory Machines

Stone Slab Cutting Machines

Stone Slab Cutting Machine

Multi-Blade Slab Cutting Line

Automatic Slab Cutting Machine

Bridge Type Circular Saw Block Cutter

Bridge Type Block Cutter

Giant Disc Saw Machine

Granite Infrared Bridge Cutting Machine

Marble Infrared Bridge Cutting Machine

Limestone Infrared Bridge Cutting Machine

Slate Infrared Bridge Cutting Machine

Sandstone Infrared Bridge Cutting Machine

Dafon Machines

Curbstone Stone Cutting Machine Line DFLSX1200-13S

Quanzhou DAFON Machinery Co., Ltd.

Mr.Danny Pan

MD

China

China

6YR

6YR

Tel:0086-150 5956 0663

Contact supplier

Guyana

2021

Guyana

2021

Danny Pan

Danny Pan