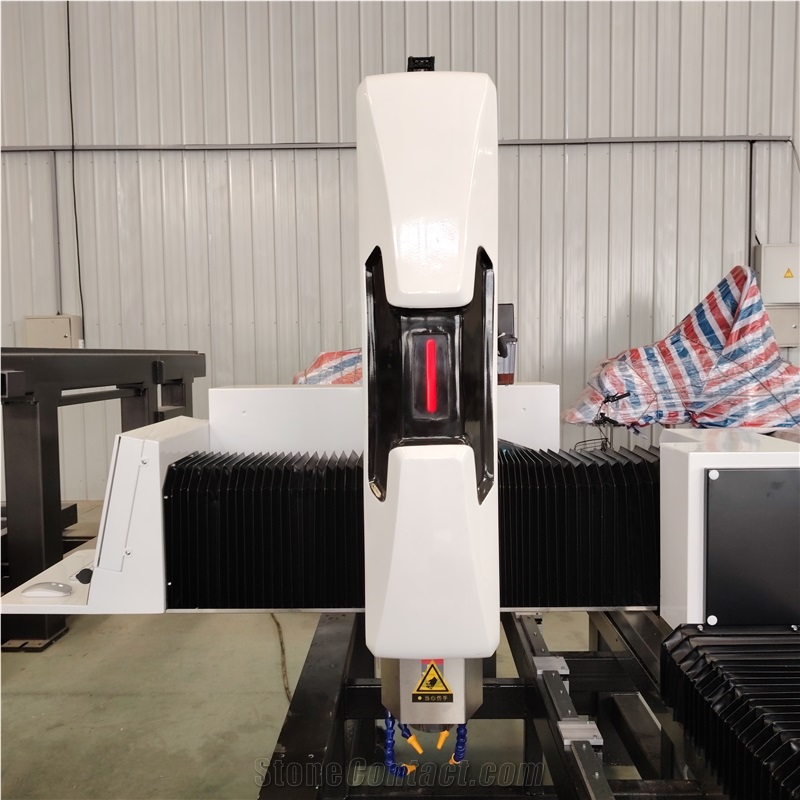

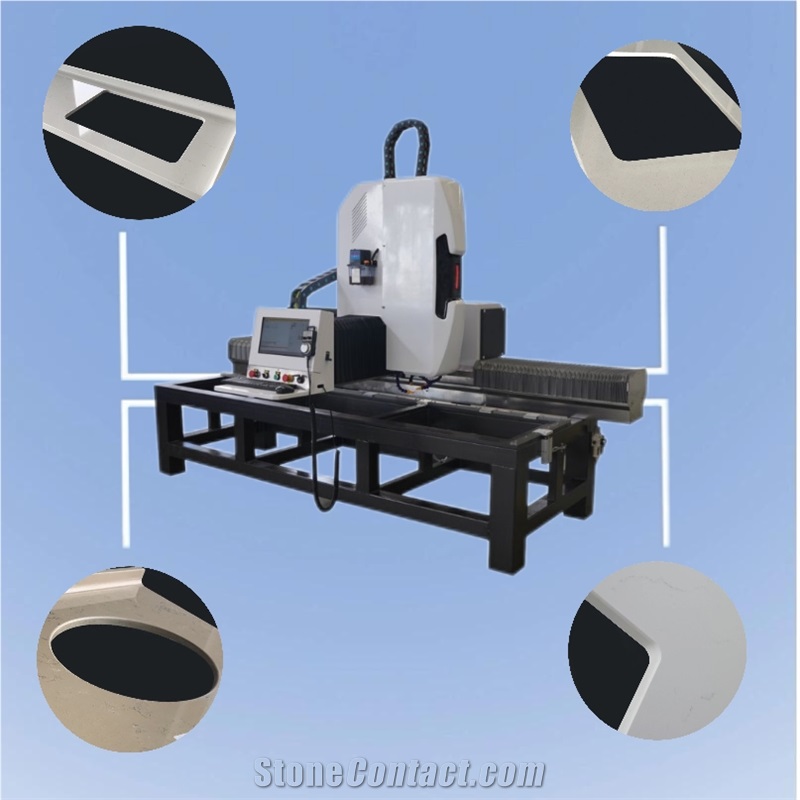

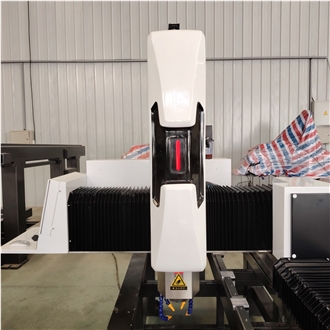

Mini Stone Hole Drilling Machine - Sink Hole Cutting Machine

FOB Price:$7600-7900

Core Functions

Target Materials

Working Principle

Parameters |

Unit |

IK206.3 |

Max. working width |

4 |

630 |

Each Spindle Motor Power |

7 |

7.5 |

Rotation speed |

45 |

24000 |

Cutting Groove Diameter |

4 |

630 |

Approx. Weight |

Kg |

1000 |

Max. working length |

4 |

2000 |

SHANLONG 3S CNC SYSTEM

SHANLONG 3S CNC System – Working Principle (Short Version)

The SHANLONG 3S CNC system is a professional motion controller used in CNC machines for stone, wood, and metal processing.

✅ How It Works:

Program Input

G-code is loaded via USB or network. Operators set parameters like speed and cutting depth.

Command Processing

The system interprets the code into movement instructions for X, Y, Z (and A) axes.

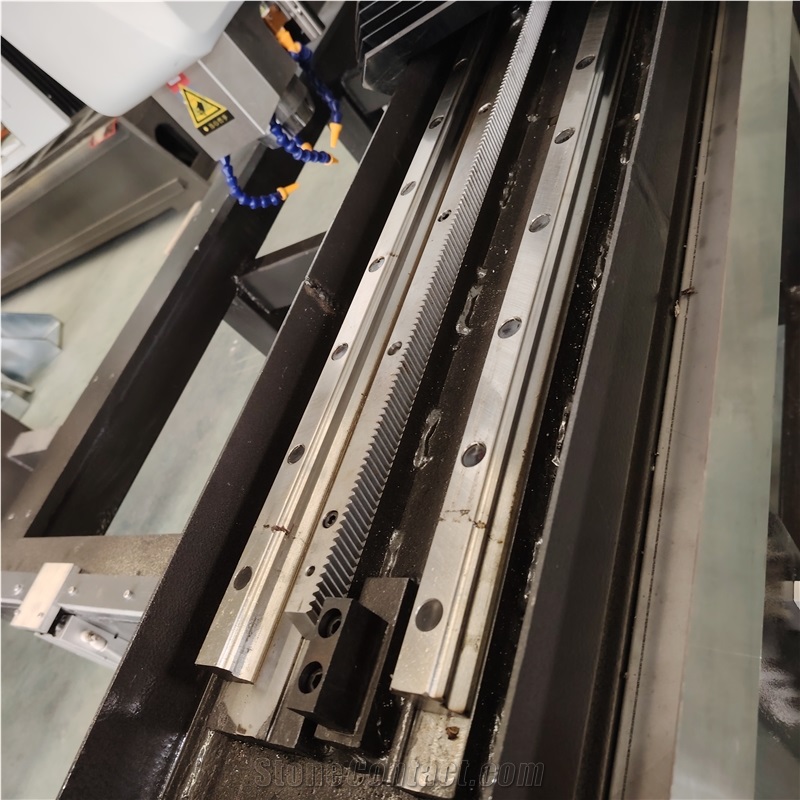

Path Control

Built-in interpolation algorithms generate precise motion paths for smooth cutting.

Motor Control

Sends pulse or analog signals to stepper/servo drivers to move the machine with high accuracy.

I/O & Feedback

Controls external devices (spindle, vacuum, coolant), supports encoder feedback for stable performance.

🌟 Key Features:

Supports multi-axis motion

User-friendly interface (English/Chinese)

Fast, accurate, and stable control

Widely used in cutting, drilling, engraving, and carving machines

4.8 / 5 Very satisfied

Phi***

8/30/2025 3:16:34 PM

Eth***

7/22/2025 3:14:39 AM

Fat***

7/21/2025 8:28:21 PM

Jas***

7/15/2025 9:14:27 AM

Related Products:

JINAN IKCNC TECHNOLOGY CO.,LTD

China

China

1YR

1YR

Tel:86-15615410983

Contact supplier