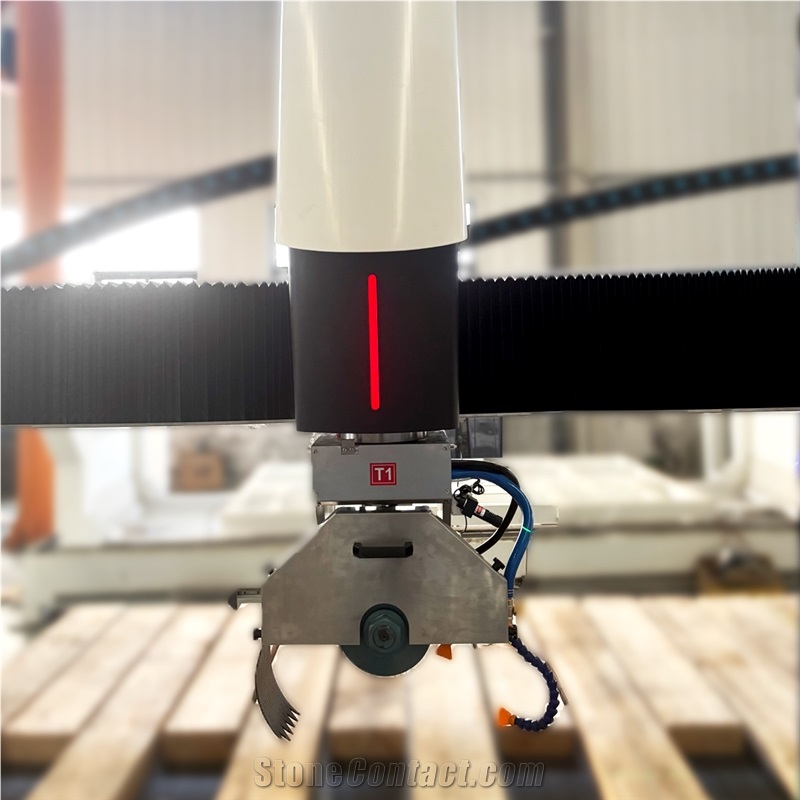

Cutting, Carving And Grinding Machine Integrated CNC Work Center

FOB Price:$19600-22100

- Dual-Mode Processing: Executes both high-precision cutting (straight lines, arcs, or custom shapes) and smooth edging (beveling, rounding, or chamfering) in a single setup, eliminating the need for multiple machines.

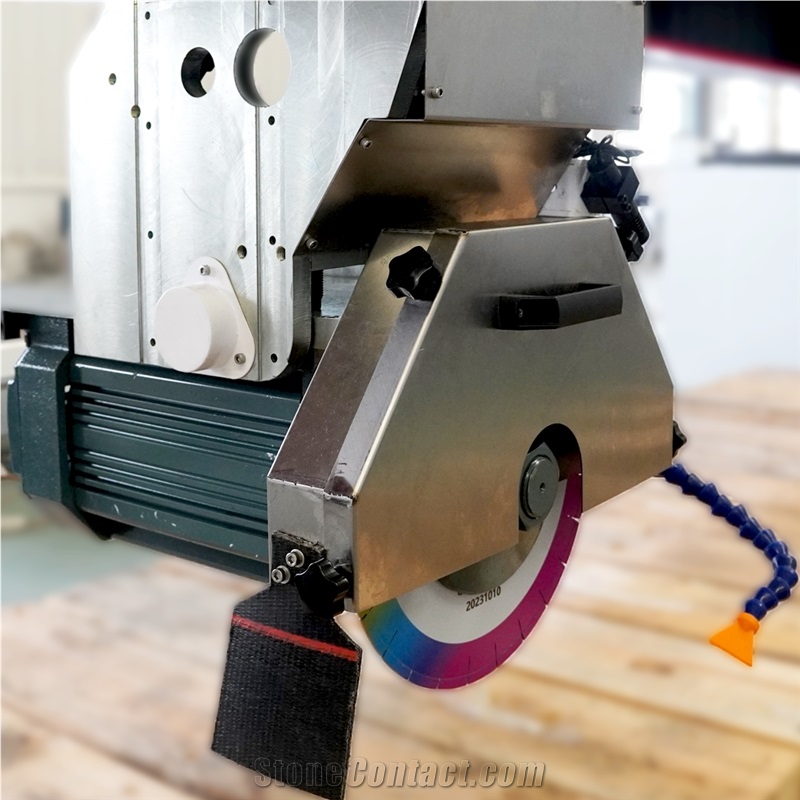

- Adaptive Material Handling: Tackles a wide range of stones—from hard granite and marble to engineered quartz and sintered stone—with adjustable cutting speed and edging pressure to match material hardness.

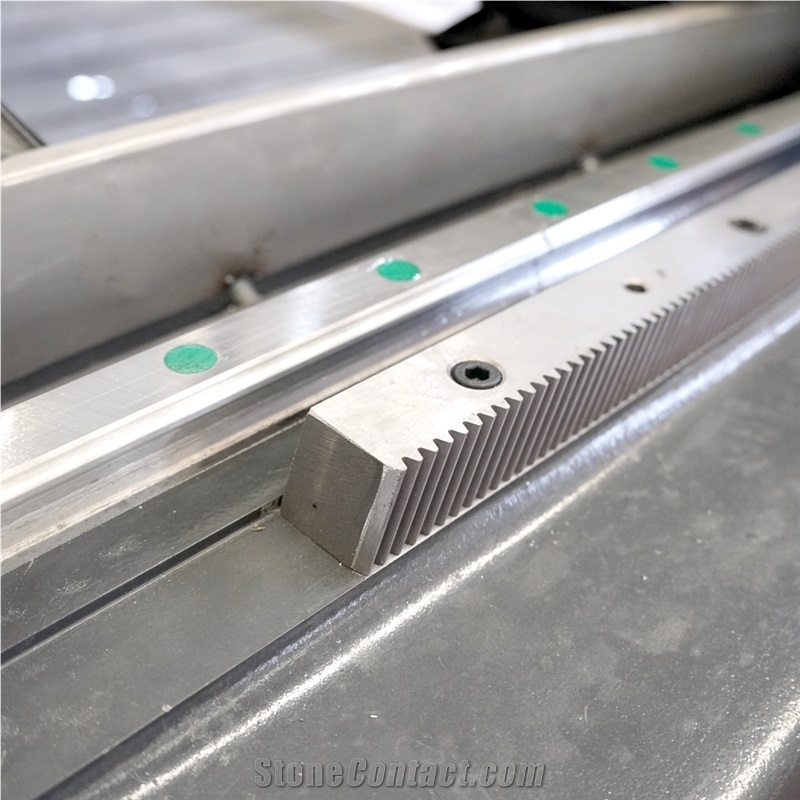

- CNC-Driven Accuracy: Equipped with advanced numerical control systems, it achieves sub-millimeter precision in cutting dimensions and edge finishes, ensuring consistent results for large batches or custom pieces (e.g., kitchen countertops, wall panels).

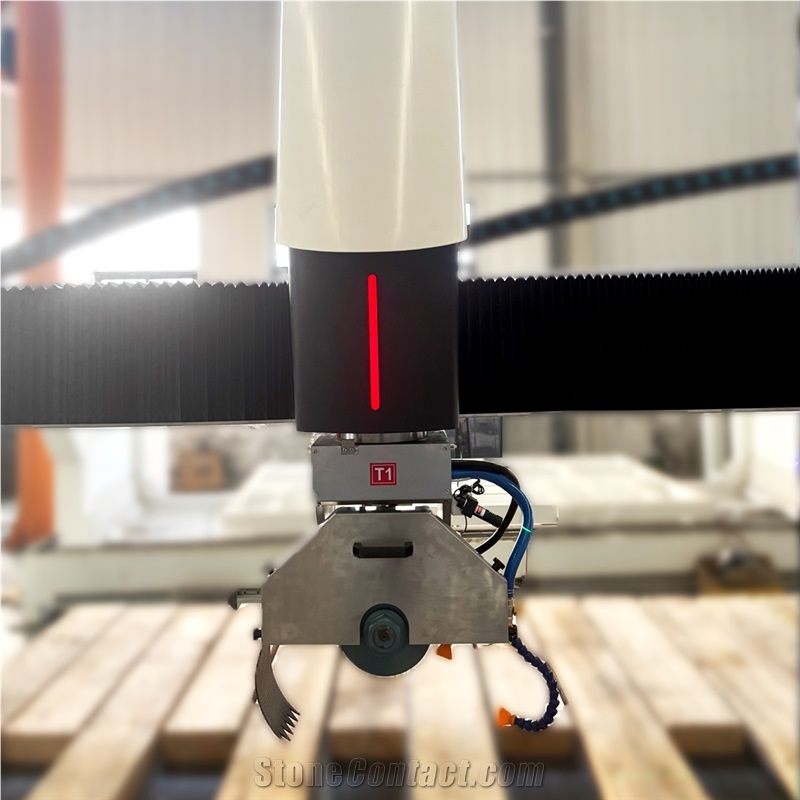

- Smart Automation: Integrates auto-positioning, tool calibration, and program storage, reducing manual intervention and minimizing errors.

- Versatile Edge Profiles: Supports diverse edge styles (e.g., bullnose, ogee, square) via quick-change tooling, adapting to design trends in interior decoration.

- High-Speed Efficiency: Optimized cutting/edging cycles shorten processing time, ideal for high-volume production while maintaining edge smoothness (no chipping or rough surfaces).

- Durable Construction: Built with heavy-duty frames and wear-resistant components to withstand continuous operation with hard stone materials.

Parameters |

Unit |

IK-3220-400 |

Machine overall height |

mm |

2600 |

Dimensions of the work table (length x width) |

mm |

3200*2000 |

Tool-holder spindle motor power |

kw |

15 |

Tool-holder spindle rotation speed |

r/min |

4000 |

Approx. Weight |

Kg |

5000 |

Max. working width |

mm |

2000 |

Max cutting depth |

cm |

7 |

Max. working length |

mm |

3200 |

Min. diameter of the blade |

mm |

350 |

Machine overall length |

mm |

6500 |

Number of axes |

nr |

3 |

Max. diameter of the blade |

mm |

400 |

Machine overall width |

mm |

3000 |

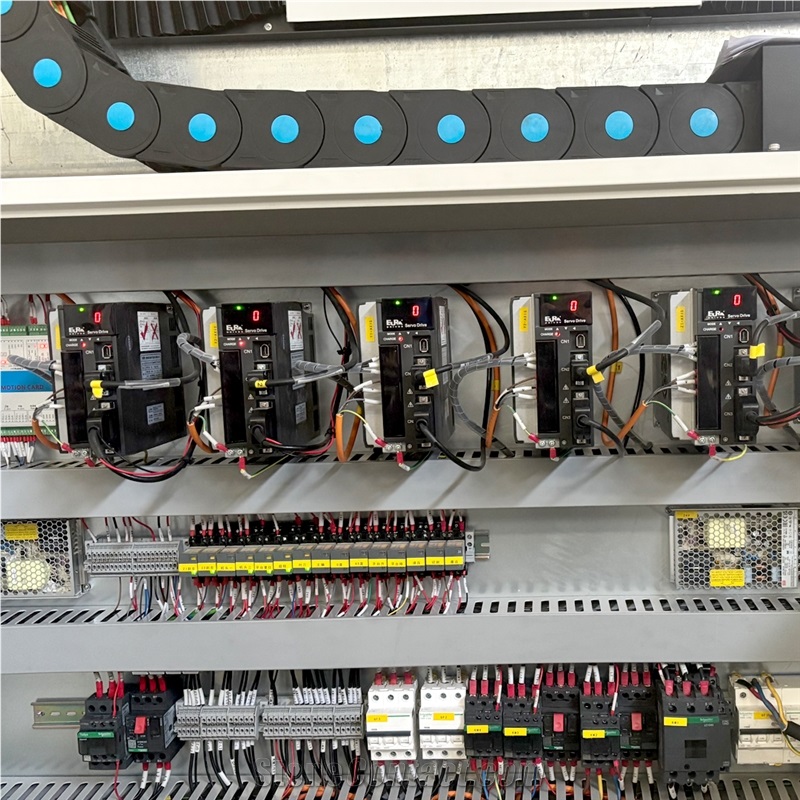

Total Power required |

kw |

18 |

Water requirement |

m3/h |

2 |

Working Principle of Weihong CNC System

1. Instruction Input and Parsing

2. Motion Control and Driving

3. Real-Time Feedback and Closed-Loop Regulation

4. Collaboration of Auxiliary Functions

Summary

The cutting-grinding all-in-one machine uses CNC control to coordinate cutting and grinding processes.

It first takes processing parameters (path, speed, etc.) and converts them into signals to drive tool movement. The diamond-tipped cutting tool rotates at high speed, cutting stone to shape while adjusting speed for material hardness.

After cutting, it switches to a grinding tool, which smooths edges by friction—controlling pressure and speed for a polished finish.

Cooling and dust removal systems run simultaneously, with real-time feedback ensuring accuracy. This integrated workflow delivers efficient, precise stone processing.

4.5 / 5 Very satisfied

Zor***

9/18/2025 1:23:03 PM

Kei***

9/8/2025 3:30:27 PM

Mal***

8/21/2025 7:13:38 PM

Moh***

8/9/2025 11:09:16 PM

Related Products:

JINAN IKCNC TECHNOLOGY CO.,LTD

China

China

1YR

1YR

Tel:86-15615410983

Contact supplier