Pedrini M739-M740 - Single disc cross cutting machines for marble and granite

FOB Price:

Type:

Stone Factory MachinesStone Tile Cutting MachinesSingle Disc Cutting Machine

Usage:

Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Remote troubleshooting, Field troubleshooting

Machinery Function Features

Single diamond disc machines for the cross cutting of marble or granite strips with predetermined length and for the production of dimensioned elements. The cutting cycle is semi-automatic and it requires the presence of the operator.

The machines can be equipped with several optional to raise the cutting thickness by means of diamond discs with up to 650 mm diameter and to increase the automation level.

These single disc machines for the production of dimensioned elements in marble, granite and natural stones perform strips cross cutting in a way perfectly orthogonal to strips reference side.

Head inverter controlled travelling speed is reduced during the final cutting phase through a sensor system that allows as well for stroke length adjustment. At the end of the cutting stroke, the strip manual positioning zone is left totally free to facilitate operator duty, whilst base sloped configuration conveys water through one sole channel located on machine rear. One control, formed by two buttons that are actuated and held actuated with both hands during the complete cutting cycle, provides the operator totally safe machine use.

The machine structure is made in large thickness normalized steel work.

As a guarantee of assembly perfect geometry, head support fixing plane, orthogonal reference plate fixing plane and entry/exit sides roll shafts mounting bores, have been machined onto monobloc base through one sole positioning on tool machine.

Cuts orthogonally reference plate is built in large thickness hardened steel and is easy replaced. All components have undergone structural inspection through the FEM (Finite Elements Method) and their precision ensures perfect machine geometry.

Machines complete surface is protected by two paint layers applied after sandblasting.

Disc-holder head is assembled onto a group that comprises two large diameter chrome plated and ground parallel rods, that have been stiffened at both ends through strong structures.

The rods slide into two long precise bushings fixed inside the robust support that is assembled onto machine base and is equipped with a simple and precise device for orthogonal adjustment.

A consistently oil lubricated gear-motor and a pinion-rack system drive the cutting stroke whilst a separate pump provides oil lubrication to bushings/rods contact areas.

On board electric panel comprises machine actuating controls and is dust and water proof in accordance to IP 54 (EN 60529) standards.

Machines are equipped with 11 stops pivoting in fixed positions for the cutting of standard dimensions and with an adjustable stop for the cutting of special dimensions and steps.

Technical Data

Parameters |

Unit |

M739GV for Granite |

M739MV for Marble |

M739PV for Lava stone, sandstone |

M740MV for Marble |

Disc/Spindle travelling speed |

m/min |

0,5 ÷ 10 |

0,5 ÷ 10 |

0,5 ÷ 10 |

0,5 ÷ 10 |

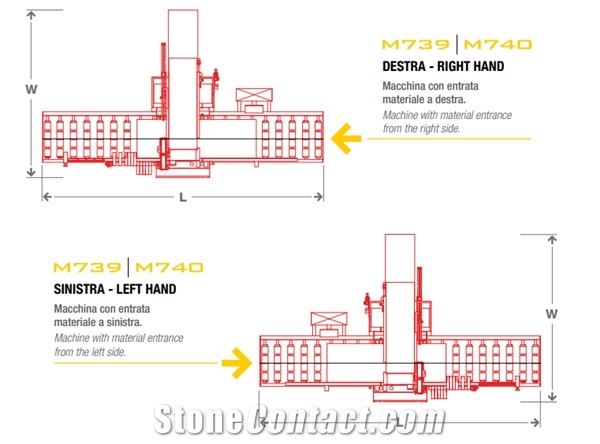

Machine width (W) |

mm |

2100 |

2100 |

2100 |

2255 |

Machine length (L) |

mm |

4700 |

4700 |

4700 |

4800 |

Maximum workable thickness |

mm |

35 |

65 (85 - 105) |

65 |

120 (200) |

Forwarding/Spindle motor power |

kw |

1,1 |

1,1 |

1,1 |

1,1 |

Cooling water (minimum pressure 1.5 bar) |

L/min |

15 |

15 |

15 |

20 |

Machine height (H) |

mm |

1520 |

1520 |

1520 |

1520 |

Max. workable material width |

mm |

650 |

650 (600) |

600 |

650 (600) |

Approximate weight |

Kg |

1700 |

1700 |

1700 |

2200 |

Discs diameter |

mm |

350 |

350 (400 - 450) |

450 |

500 (650) |

Discs number |

nr |

1 |

1 |

1 |

1 |

Installed electrical power |

kw |

6.4 |

7.7 |

8.1 |

14.3 |

11 pivoting stops for fixed dimensions |

mm |

200 ÷ 800 |

200 ÷ 800 |

200 ÷ 800 |

200 ÷ 800 |

Disc flange |

mm |

186 |

186 |

186 |

214 |

Disc motor power |

kw |

5.3 |

6.6 |

7 |

13.2 |

Reviews

No Reviews

Related Products:

Single Disc Cutting Machine

Machinery

Stone Factory Machines

Stone Tile Cutting Machines

Granite Single Disc Cutting Machine

Marble Single Disc Cutting Machine

Limestone Single Disc Cutting Machine

Onyx Single Disc Cutting Machine

Basalt Single Disc Cutting Machine

Quartzite Single Disc Cutting Machine

Sandstone Single Disc Cutting Machine

Travertine Single Disc Cutting Machine

Pedrini Machines

Pedrini M739-M740 - Single disc cross cutting machines for marble and granite

Ms.Giambattista Pedrini

CEO

Italy

Italy

Tel:+39 35 4259111

Contact supplier

Giambattista Pedrini

Giambattista Pedrini