SYSTAR XL- Stone Fab Center & Cutting Machine - Miter Saw

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesSink Hole Cutting Machine

Usage:

Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Remote troubleshooting

Machinery Function Features

SYSTAR XL is a top-end stone fab center, stone cutting machine and mitre saw in one. Thanks to the high-end linear guides and a non-vibrating steel frame, it performs accurate straight and miter cuts.

WHICH PROBLEM DOES IT SOLVE FOR THE STONE FABRICATOR?

The highly precise V cut allows the edges to appear as a natural continuity of the veins, exalting the material (and the abilities of the marble worker).

You’ll create and finish big islands or L-shaped worktops out of one piece, without moving the slab

WHAT WILL YOU CREATE?

worktops

L-shaped islands

backsplash

fireplaces

arches

architectural elements

sills & stairs

STONE PROCESSING TYPES

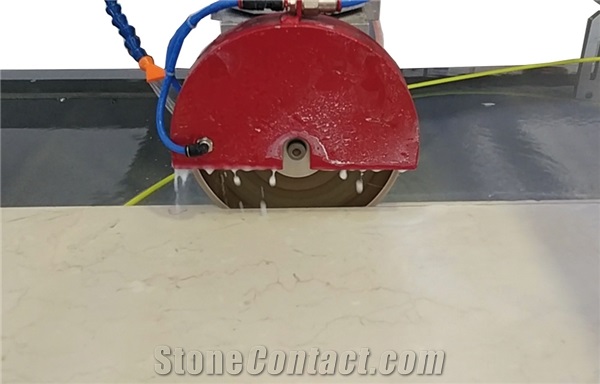

stone cutting: 4 sides at 90°/45°

shaping and polishing (internal and external)

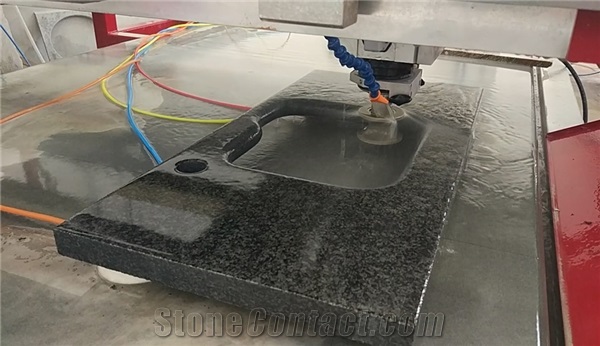

cutting out sink holes (also by blade)

recessed drainer/drain grooves

slots on edges

edge polishing (on straight and inclined edges)

WHAT WILL YOU LOVE IN THIS FABRICATION WORK CENTER?

Large work strokes

Open frame (no-limits for the length of the slab)

9 spindle positions

Fast tool change

WORK TABLE

Work table 3.000 x 1.200 mm, made of natural stone, calibrated on the machine itself

WORK PIECE DIMENSIONS

- Height: max.140 mm, placed on suction cups (h=40 mm)

- Width: max. 1.650 mm

- Length: no limits

OPERATIONAL WORK STROKES:

- Profile tools: 3.550 x 1.470 mm

- Vertical cut: 3.550 x 1.540 mm (max.)

- 45° mitre cut: 3.350 x 1.270 mm

- Edge polishing: 3.400 x 1400 mm (max.)

FRAMEWORKS

- Tubular steel frame coated with ceramic and epoxy paint

- Dimensions: 4.000 x 2.000 x 1.950(h) mm

- Weight:1.220 kg

TEMPLATE ON TOP

Fixed by 4 suction cups Ø120 mm

OPERATING HEAD

- Electrospindle: 2.2 kW with internal lubrication.

- Spindle:

● Stainless steel

● Connection: ½” gas F

● Rotation speed: from 1.500 to 12.500 rpm (controlled by vector drive)

- Vertical movement: automatic by electromotor

- Vertical stroke: 210 mm

- 9 spindle positions:

● Vertical (for profiling and slot cutting)

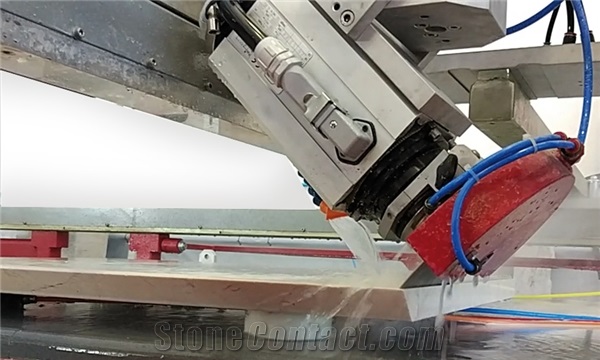

● 45° inclination (for disc cutting and bevel polishing) in 4 different positions: 0°, +/- 90°, 180°

● Horizontal (for disc cutting and edge polishing) in 4 different positions: 0°, +/-90°, 180°

- Pneumatic lifting of the operating head

- Automatic internal and external tool lubrication (starts when motor is started).

ORTHOGONAL MOVEMENTS

- Adjustable to limit the work area

- Slide guides are equipped with adjustable mechanical limit switches.

VACUUM TO FIX THE WORKPIECE AND TEMPLATE

2 vacuum circuits with 6 connections each hold the work piece and template firmly in position:

- 2 Vacuum ejector pumps

- 2 Pressure regulators

- 2 Manometers

- 8 Suction cups work piece: no. 6 Ø90 mm, no. 2 Ø70 mm, can be excluded individually

- 4 Suction cups template: no. 4 Ø120 mm with internal thread

- Connection pipes: 4 m, Ø 6 mm

WATER CONNECTION

- Tool lubrication: internal through spindle and by 2 external water hoses

- Water pistol

SUPPLY

- Electrical power: 230 V–50/60 Hz single-phase (18A)

- Pneumatic: min. pressure 6 bar, 150 l/min

recommended: compressor minimum 4 kW, 300 l/min, 8 bar pressure

- Water: min. pressure 2 bar, 15 l/min

Technical Data

Parameters |

Unit |

SYSTAR XL |

Min. Cooling water pressure |

bar |

2 |

Vertical stroke |

mm |

210 |

Min. Air pressure |

bar |

6 |

Work table |

mm |

3000 x 1200 |

Work strokes for 45° mitre cut |

mm |

3350 x 1270 |

Water consumption |

L/min |

15 |

Rotation speed |

rpm |

1.500 to 12.500 |

Machine overall length |

mm |

4000 |

Machine overall height |

mm |

1950 |

Main motor power |

kw |

2.2 |

Machine overall width |

mm |

2000 |

Air consumption |

L/min |

150 |

Approx. Weight |

Kg |

1220 |

Electrical power |

v |

230 V–50/60 Hz single-phase (18A) |

Work strokes for Vertical cut |

mm |

3550 x 1540 (max.) |

Work strokes for Edge polishing |

mm |

3400 x 1400 (max.) |

Max. Processing Width |

mm |

1650 |

Max. processing thickness |

mm |

max.140, placed on suction cups (h=40 mm) |

Work strokes for profile tools |

mm |

3550 x 1470 |

Reviews

No Reviews

Related Products:

Sink Hole Cutting Machine

Machinery

Stone Factory Machines

Stone Finishing, Profiling Machines

Granite Sink Hole Cutting Machine

Marble Sink Hole Cutting Machine

Limestone Sink Hole Cutting Machine

Artificial Stone Sink Hole Cutting Machine

Basalt Sink Hole Cutting Machine

Quartzite Sink Hole Cutting Machine

Ghines Machines

SYSTAR XL- Stone Fab Center & Cutting Machine - Miter Saw

Mr.Andrea Gabellini

Sales Manager

Italy

Italy

Tel:+39-541 751080

Contact supplier

Andrea Gabellini

Andrea Gabellini