2025 High Benefit Ultra Thin Multiwire Saw Stone Block Cutting Machine

FOB Price:$253500-260000

Ultra-Thin Multi-Wire Saw - Redefining Efficiency

Trends of Tomorrow, Your next machine for block cutting for much more benefit.

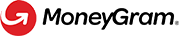

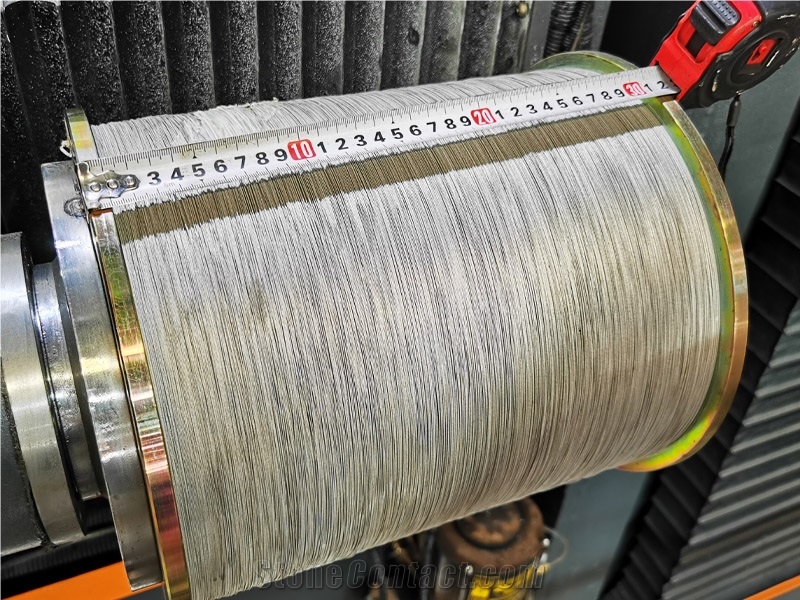

Hualong new multi-wire cutting machine HLMW-100/150 represents a significant leap in the way stone is processed. Using cutting-edge technology and ultra thin diamond wire with 0.35-0.8mm diameter, it's well done to cut marble, granite and ornamental rocks in different thickness efficiently. Thanks to an easy user control system and its patent structure birations free, it allows a longer life of the wire and an unparalleled reliability.

Key Advantage:

1) High yield: 97%+ material utilization with 0.4-0.7mm kerf, 15-20% higher than conventional saws

2) Eco-Friendly: 90% less dust, 40dB noise reduction, 50% energy saving.

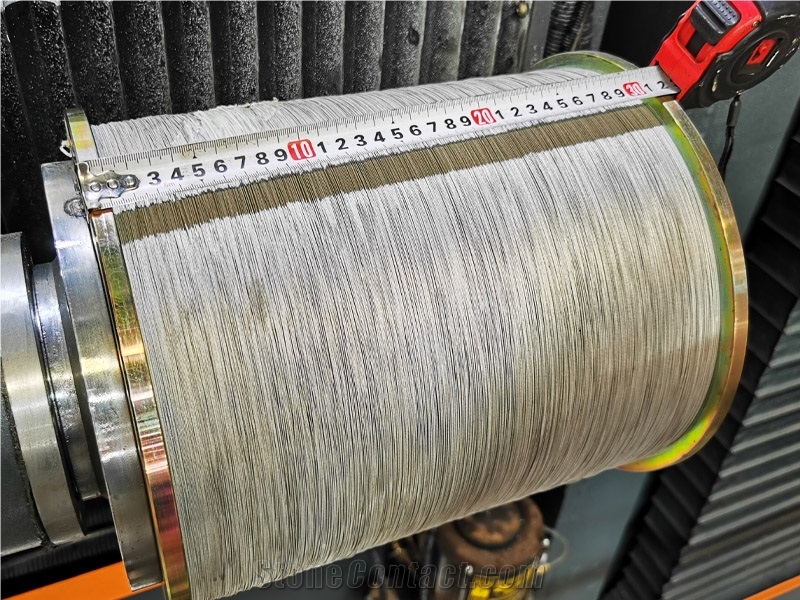

3) Ultra-Thin Cutting: Produce slabs below 10mm with 50% better flatness and zero wire marks.

4) Space-Saving: 30% smaller footprint for space-constrained workshops.

The use of such advanced cutting technology means quality, efficiency and profit. This trend also reflects a broader movement towards sustainable practices in the industry. By reducing waste, manufacturers are not only cutting costs but also minimizing their environmental footprint. The efficient use of resources is increasingly important in modern manufacturing, and the stone industry's adoption of this leading technologies is a prime example of this shift.

Parameters |

Unit |

HLMW-100/150 |

Machine width (W) |

mm |

4800 |

Down speed |

cm/h |

5-1200 |

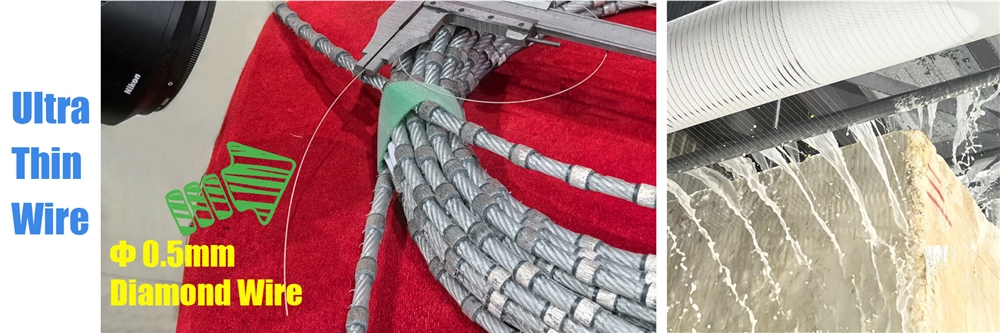

Max. volume of stored wire |

km |

40/80 |

Max.tension |

N |

260 |

Machine height (H) |

mm |

7445 |

Max. Cutting width |

mm |

2000 |

Max. spindle speed |

rpm/min |

3000 |

Diamond wires speed |

m/s |

25-40 |

Machine length (L) |

mm |

10160 |

Voltage/Frequency |

V/Hz |

380/60 |

Max. Cutting height |

mm |

2100 |

Main motor power |

kw |

60 x 4 |

Max. Cutting length |

mm |

3300 |

Diamond wire diameter |

mm |

0.3-0.8 |

Slabs nominal thickness |

mm |

5-30 |

Contrast of 3 Block Cutting Machines

The output of ultra thin multiwire is 15% more than gang saw and 20% more than traditional wire/rope saw. Because diameter difference means yield difference.

| HLMW-100/150 -- Diameter of diamond wire saw | 0.3-0.8mm |

| Traditional -- Diameter of diamond wire/rope saw | 5.3-7.3mm |

| Gang saw -- Thickness of belt saw with segments | 2.2 - 3.5mm |

Tense and steady thin wire cutting make surface flatness within +/- 0.3mm

It is never too late to upgrade equipment for more value and less consumption.

Get an extra profit of USD260000, one free HLMW-100/150 machine, within 6 months. Just let HLMW-100/150 create for you !

-

Safe work platform for replacing wires

-

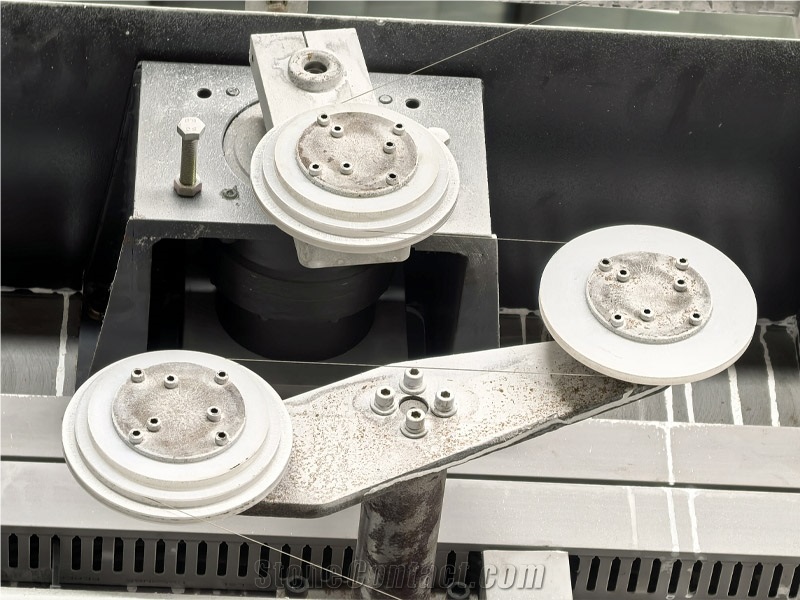

Servo motors for high move adjustment accracy

-

Four PU-coated guiding rollers with wire grooves

-

Electrical cabinet

-

Ultra thin diamond wire

¥Payment Required -

Strong stand structure with two sturdy columns

-

Air conditioner for the electrical cabinet

-

Block trolley

-

with touch screen

-

Diamond wire spools

5 / 5 Very satisfied

Yeh***

6/18/2025 2:22:10 PM

ASM***

4/17/2025 9:05:35 PM

Related Products:

Fujian Province Hualong Machinery Co.,Ltd

Sales Manager

China

China

3YR

3YR

Tel:0086-18705943969

Contact supplier

Tina Chen

Tina Chen