Multi Blade Giant Disc Saw Stone Block Cutting Machine (Max 18 Blades)

FOB Price:$30000-34000

SQC2200/2500/2800-4D Pro Multi-Blade Bridge Block Cutting Machine(pro heavy duty large cutting machine)/18 disc.

SQC2200/2500/2800-4D Pro Block Cutting Machine(18 disc.).This series machine adopts microcomputer control system and human-machine interface, uses inverter to control left-right feeding, adjusts the speed according to the stone material.

It uses hydraulic lifting system , combination of chrome-plated guide pin and wear guide bush, with small gap , wearable, beautiful structure , and guide sleeve with multi-layer seals , with waterproof , dust-proof , anti-spill , improving the service life, main motor uses brand energy-efficient motor, reduces the later using cost; forward-backward automatic slicing uses high-precision screw nut driving, main spare parts adopt imported good-quality materials; The block can be placed in the ground directly to save worktable and its maintenance costs; thus the whole machine is featured as high cutting efficiency, high slicing precision, and flatness of plate after cutting, high stability, easy-operating to suit specially cutting granite and marble block with high value and big size.

Main Feature:

1.Taiwan famous hydraulic system.The hydraulic components from Taiwan first-line brand,react more quickly,works more stable;

2.Domestic premium brand main motor with high efficiency and more energy saving,make the cutting more powerful,and saving electricity more;

3.Germany Siemens inverter, feeding more stable; imported or domestic famous brand electrical components, with lower failure rate, help you to worry less and save more labor;

4.Side-beam rails use slide V-rail, contacting area is large, not easy to shake when cutting, ensure the plate/slabs are flatness after cutting; meanwhile,the forward and backward slicing take high precision screw-nut transmission, have automatic slicing function;

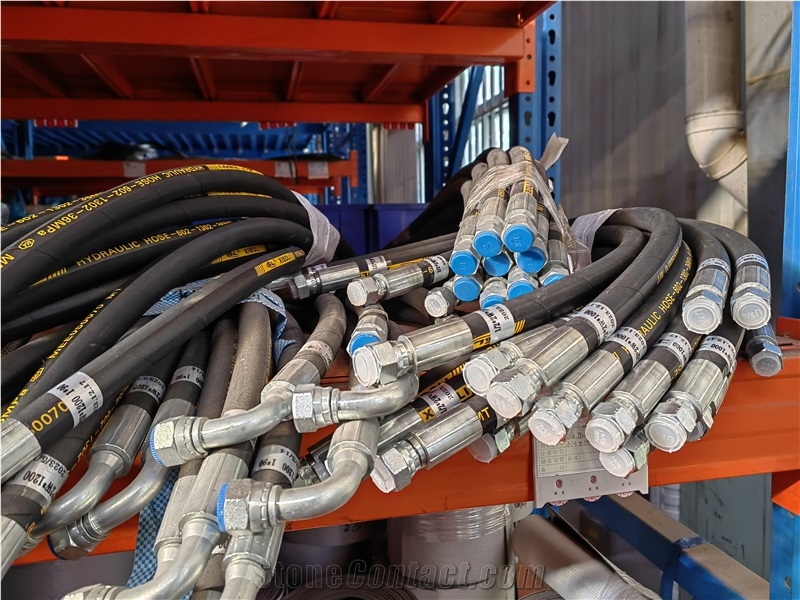

5.It uses hydraulic lifting system, combination of chrome-plated guide pin and wear guide bush, with small gap, wearable, beautiful structure, and guide sleeve with multi-layer seals, with waterproof, dust-proof, anti-spill, improving the service life;

6.Revolving working platform (Optional);

Parameters |

Unit |

SQC2200-4D Pro |

SQC2500-4D Pro |

SQC2800-4D Pro |

Usefull cutting height |

mm |

950 |

1100 |

2250 |

Cut motor power |

kw |

45 |

55 |

65 |

Approximate Weight |

Kg |

16000 |

16500 |

17000 |

Maximum disc stroke |

mm |

1350 |

1350 |

1350 |

Maximum block length |

mm |

5800 |

5500 |

5200 |

Machine width |

mm |

4400 |

4400 |

4400 |

Maximum block height |

mm |

>2000 |

>2000 |

>2000 |

Maximum machine width |

mm |

6200 |

6200 |

6200 |

Maximum block width |

mm |

4000 |

4000 |

4000 |

Cooling water (1.5 bar pressure) |

m3/h |

15 |

15 |

15 |

Disc diameter |

mm |

400~2200 |

400~2500 |

400~2800 |

Installed power |

kw |

56 |

66 |

76 |

Machine front dimension |

mm |

10000 |

10000 |

10000 |

PLC control system. This series machine adopts microcomputer control system and human-machine interface, uses inverter to control left-right feeding, adjusts the speed according to the stone material.

It uses hydraulic lifting system , combination of chrome-plated guide pin and wear guide bush, with small gap , wearable, beautiful structure , and guide sleeve with multi-layer seals , with waterproof , dust-proof , anti-spill , improving the service life, main motor uses brand energy-efficient motor, reduces the later using cost; forward-backward automatic slicing uses high-precision screw nut driving, main spare parts adopt imported good-quality materials; The block can be placed in the ground directly to save worktable and its maintenance costs; thus the whole machine is featured as high cutting efficiency, high slicing precision, and flatness of plate after cutting, high stability, easy-operating to suit specially cutting granite and marble block with high value and big size.

4.5 / 5 Very satisfied

lew***

7/28/2025 4:27:20 AM

Dia***

7/25/2025 5:04:21 PM

Related Products:

FUJIAN JOBORN MACHINERY CO.,LTD.

Sales Person

China

China

4YR

4YR

Tel:86-17350913972

Contact supplier

Frank Chow

Frank Chow