High Speed Laser Bridge Saw Stone Cutting Machine For Granite & Marble

FOB Price:$16500-20500

Parameters |

Unit |

SQC450-4D GT |

SQC600-4D GT |

SQC700-4D GT |

Installed electrical power |

7 |

21 |

24.5 |

28 |

Disc motor power |

7 |

15 |

18.5 |

22 |

Discs number |

73 |

1 |

1 |

1 |

Max. workable material width |

4 |

2000 |

2000 |

2000 |

Maximum cutting width |

4 |

2000 |

2000 |

2000 |

Machine width (W) |

4 |

4800 |

4800 |

4800 |

Cooling water (minimum pressure 1.5 bar) |

30 |

3 |

3 |

3 |

Discs diameter |

4 |

450 |

600 |

700 |

Average level of sound power |

66 |

80 |

80 |

80 |

Maximum workable thickness |

4 |

100 |

180 |

230 |

Machine height (H) |

4 |

3000 |

3200 |

3400 |

Output |

m2/day(24Hrs) |

180~250 |

180~250 |

180~250 |

Approximate weight |

26 |

5700 |

5800 |

5900 |

Machine length (L) |

4 |

6000 |

6000 |

6000 |

Minimum strip length |

4 |

200 |

200 |

200 |

Min. workable material width |

4 |

100 |

100 |

100 |

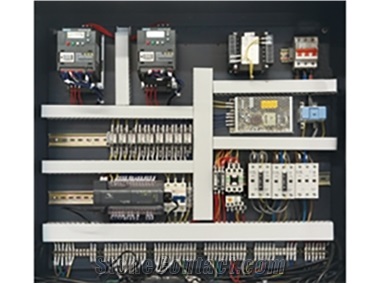

This machine adopts the PLC control system, using Chinese, English, Russian, Arabic, with the best human-computer interaction interface, the operation interface is a combination of touch screen and mechanical button to control the interface, input operating parameters through interface (including cutting size specification, moving speed) Etc., the cutting process is automated and programmed.

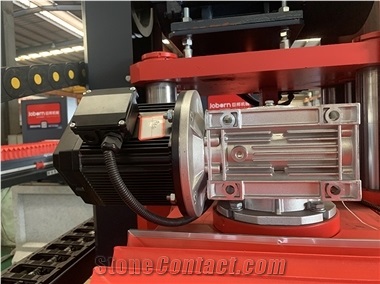

Mechanical part: The main engine is a four-guide column lifting, solid chrome plated guide column of 80mm diameter, wear-resistant guide sleeve of ductile cast iron, all four guide columns are oil-immersed lubrication, the upper and lower link plates are cast as a whole, the automatic hydraulic rotating table 3200*2000mm(reversible), the work table stage frame is made of national standard 150mm H-beam steel. The middle frame and bottom frame are made of national standard 140mm channel steel, the workbench is supported by 6 rollers, and the bearing in the main shaft box is arranged in the front 2+ back 2 structure;

Electrical part: PLC computer operating system, LCD touch screen(7 inches) using Chinese, English, Russian, Arabic operation interface, vertical movement, horizontal movement are driven by servo, the main motor are 15kW-4P/18.5kW-4P/22kW-4P;

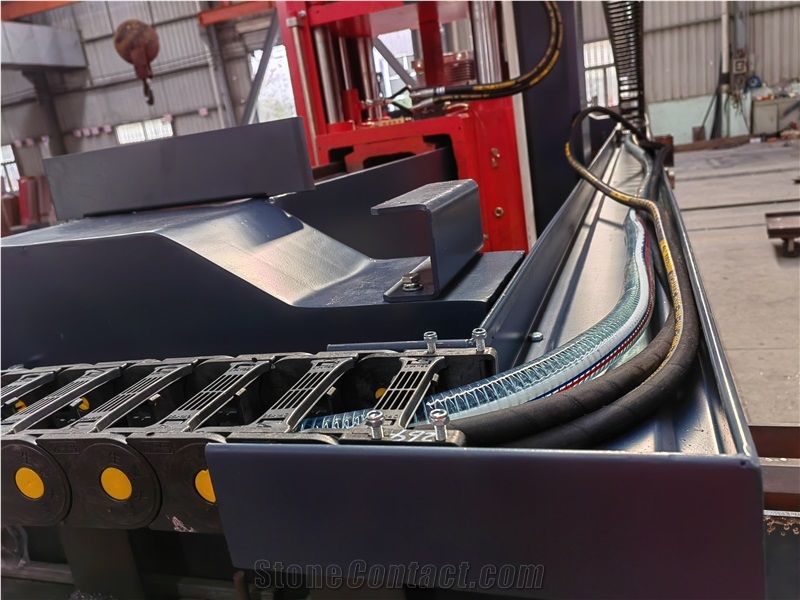

Hydraulic part: host double hydraulic lifting, 90 degree table rotation for hydraulic cylinder drive, 360 degree table rotation for hydraulic motor drive, table flip are double hydraulic cylinder drive, Taiwan first-line brand solenoid valve, double thickened high-pressure tubing;

No Reviews

Related Products:

FUJIAN JOBORN MACHINERY CO.,LTD.

Sales Person

China

China

4YR

4YR

Tel:86-17350913972

Contact supplier

Frank Chow

Frank Chow