Visual Intelligence Bridge Cutting Machine For Cutting Slabs

FOB Price:$17000-19000

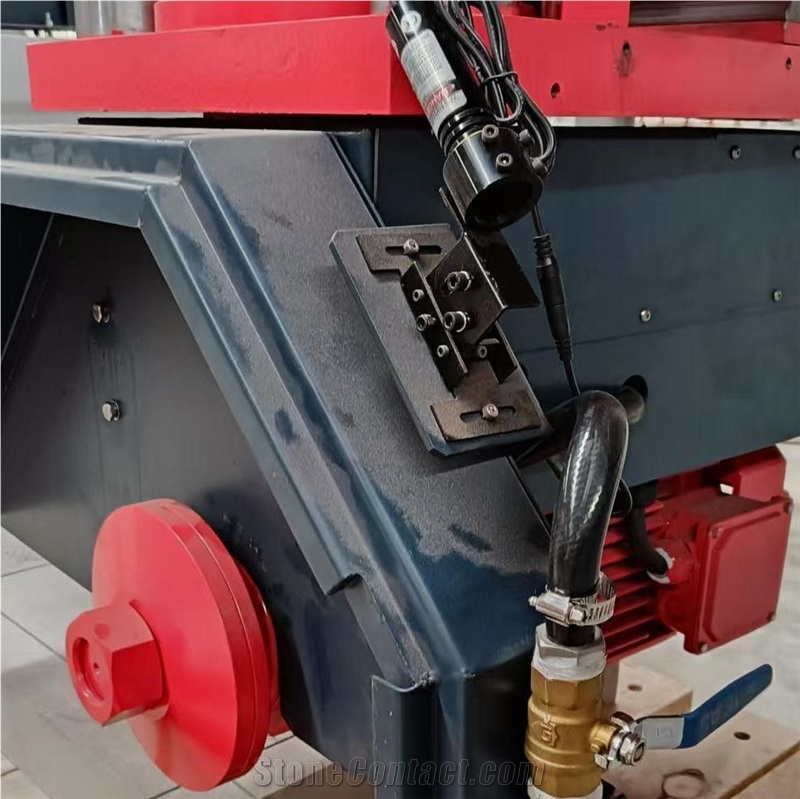

SQC600-4D SVI Visual Intelligent Infrared Bridge Cutting Machine (Cutting head Rotatable)

Standard Instructions:

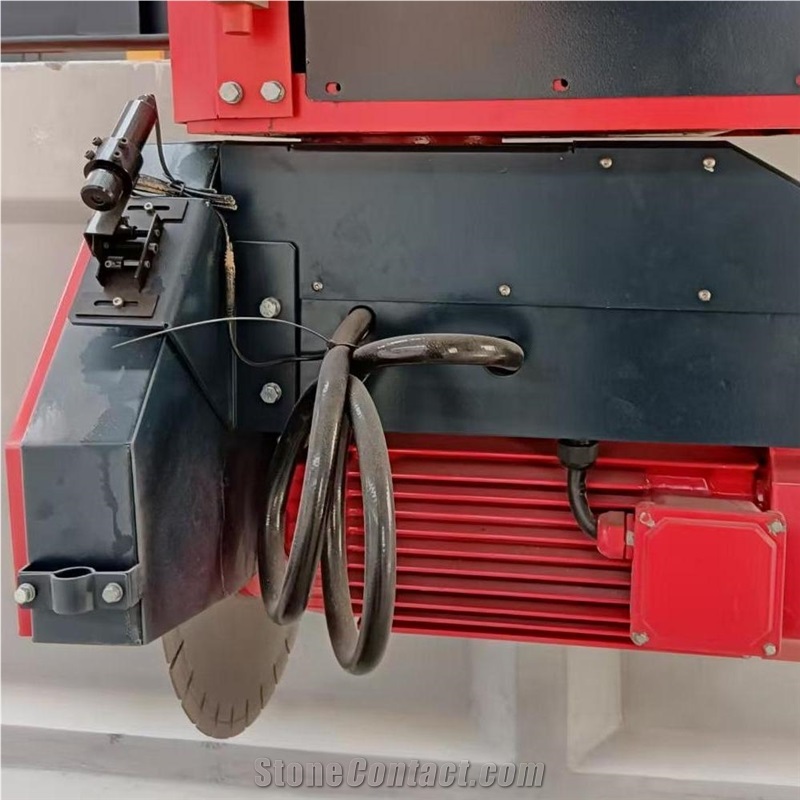

Mechanical part: The main engine is a four-guide column lifting, solid chrome plated guide column of 80mm diameter, wear-resistant guide sleeve of ductile cast iron, all four guide columns are oil-immersed lubrication, the upper and lower link plates are cast as a whole, the automatic hydraulic tiltable worktable 3200*2000mm(tilt range 85 degree);

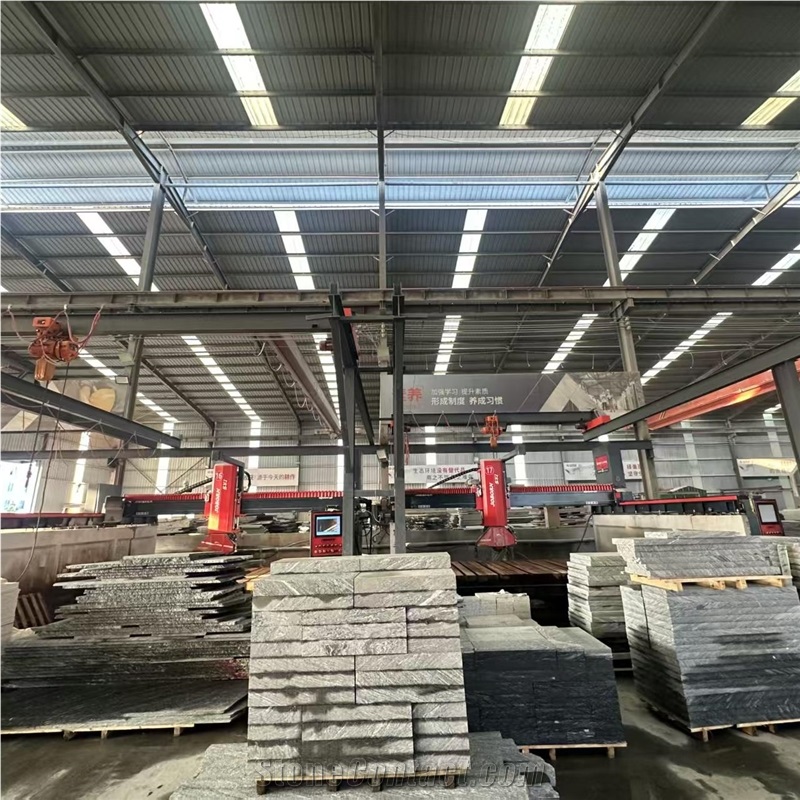

The equipment is equipped with high-definition industrial cameras and visual AI system, which has high processing precision, easy adjustment and good stability. Humanized human-machine interface, support file import, can automatically identify the outline size of the slab; Automatic and continuous cutting process, no need to stop the worktable and manual adjust again, a person can operate more than 2 machines, can greatly reduce labor costs;

Electrical part: computer operating system, LCD touch screen with humanized human-machine interface, the main motor is 22kW-4P;

Hydraulic part: double hydraulic lifting of the main engine, double hydraulic cylinder drive of the worktable, Taiwan's first-line brand solenoid valve, double-layer thickened high-pressure oil pipe;

Parameters |

Unit |

SQC600-4D SVI |

Blade diameter |

mm |

600 |

Main motor power |

kw |

22 |

Z Axis Stroke |

mm |

350 |

Max. thickness cutting capacity |

mm |

180 |

Working table tilting angle |

° |

85 |

Machine height |

mm |

3100 |

Cooling water requirement(1.5 bar min. pressure) |

m3/h |

3 |

Machine width |

mm |

4800 |

Working table dimensions(L×W) |

mm |

3200*2000 |

Cutter rotating angle |

° |

0/90 |

Machine length |

mm |

6000 |

Max. working dimensions(L×W×H) |

mm |

3200*2000*180 |

The equipment is equipped with high-definition industrial cameras and visual AI system, which has high processing precision, easy adjustment and good stability. The system provides ordinary infrared bridge cutting mode and visual AI automatic matching cutting mode,to meet various needs; Humanized human-machine interface, support file import, can automatically identify the outline size of the slab; Automatic and continuous cutting process, no need to stop the worktable and manual adjust again, a person can operate more than 2 machines, can greatly reduce labor costs;

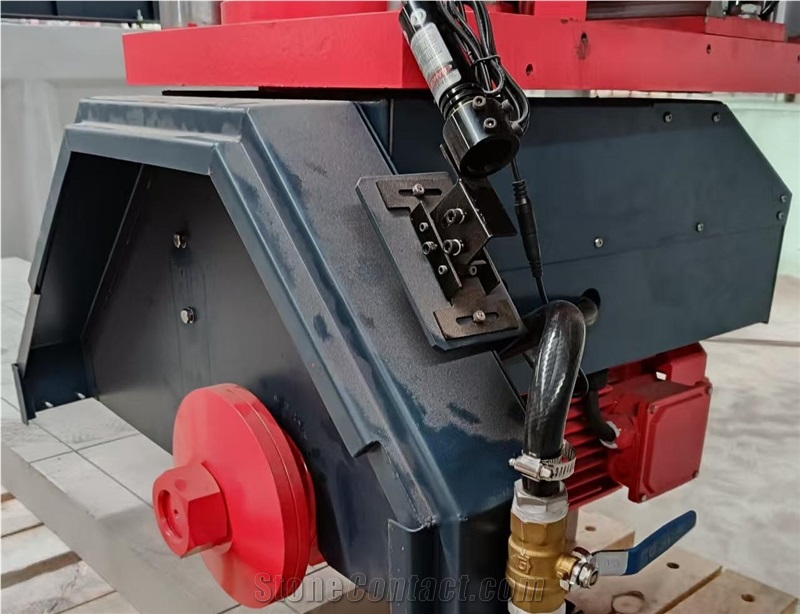

1- Equipped with HD industrial camera, can automatically identify the outline size of the slab;

2- The head rotates 0°/90°, the worktable can be tilt 85°, compared with ordinary infrared bridge cutting machine, it is high accuracy, easy adjustment abd better stability;

3- The cutting process is automatically continuous, and there is no need to stop the worktable and manually set the tool again in the middle;

4- No need to print orders, the system optimization algorithm, automatic matching size layout;

5- Can choose to automatically avoid the fault flow (stone gall, stone line, crack), automatic anew typesetting;

6- The system supports electronic orders, which can be deducted and marked automatically;

7- The system provides ordinary infrared bridge cutting mode and visual AI automatic matching cutting mode,to meet various needs;

8- Visual AI system, one person can operate more than two machines, reducing labor costs.

5 / 5 Very satisfied

LEE***

7/17/2025 7:03:57 AM

Chr***

7/16/2025 4:27:58 AM

Related Products:

FUJIAN JOBORN MACHINERY CO.,LTD.

Sales Person

China

China

4YR

4YR

Tel:86-17350913972

Contact supplier

Frank Chow

Frank Chow