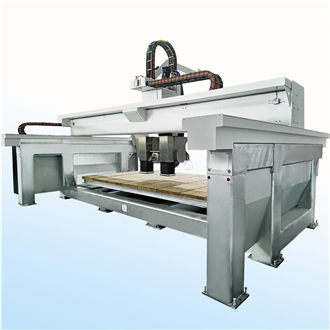

Best 5 Axis Italian CNC Bridge Marble Cutting Machine For Countertops

FOB Price:$46500-49500

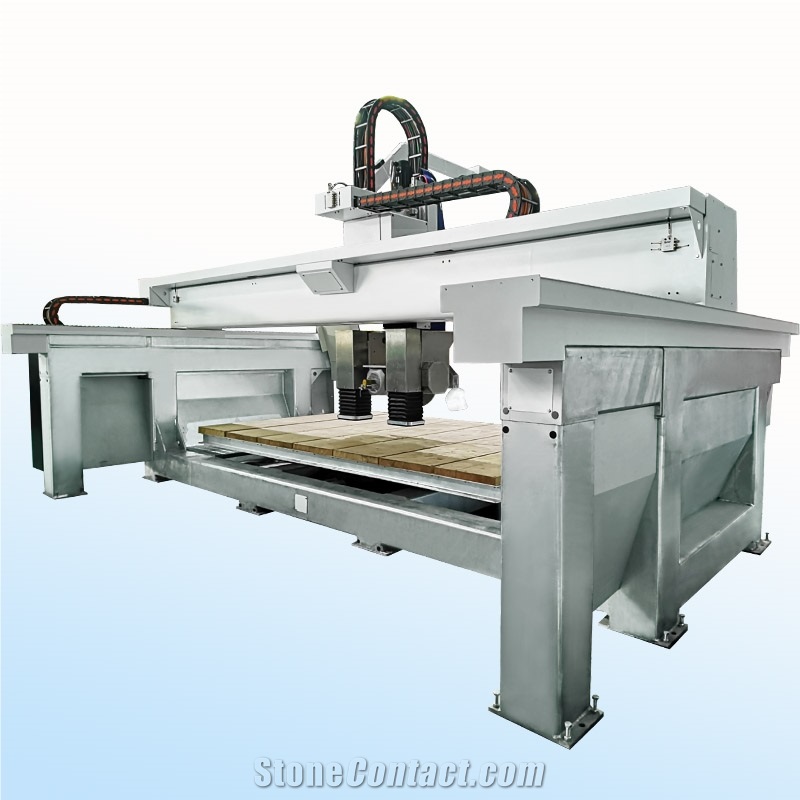

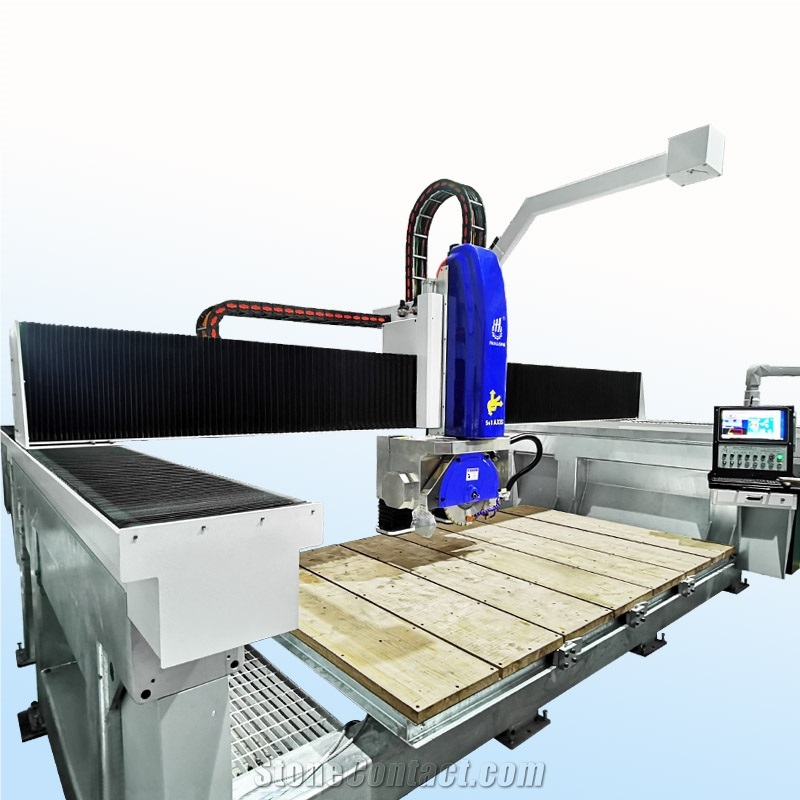

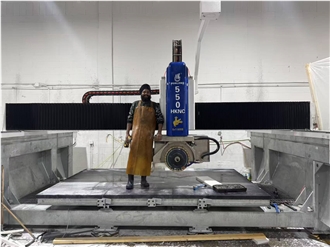

Hualong HKNC-550 5-Axis Bridge Saw is a high-precision CNC machine designed for advanced stone processing, featuring Italian ESA CNC system and Pegasus Zeus software. Ideal for kitchen countertops, vanity tops, and architectural stonework.

✅ Key Advantages:

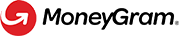

- RV Reducer C-Axis: ±0.005° rotation accuracy for smooth contour cutting

- Dual Servo Y-Axis: Enhanced stability with 30% faster acceleration

- Reinforced Frame (700kg heavier): 40% less vibration for heavy-duty production

- Camera-Assisted Nesting: Manual defect marking for optimal material usage

✅ Applications:

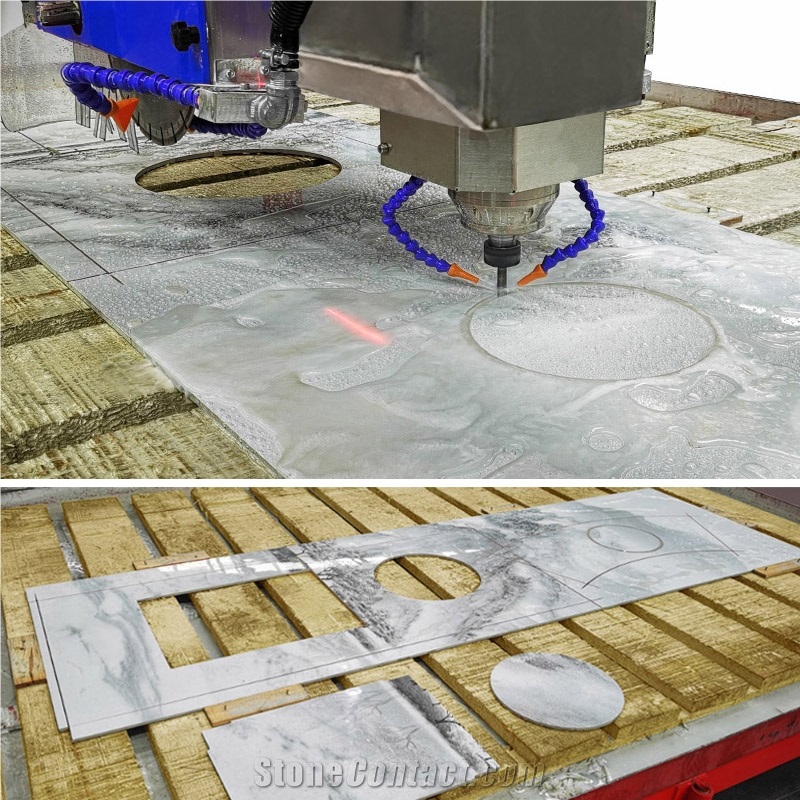

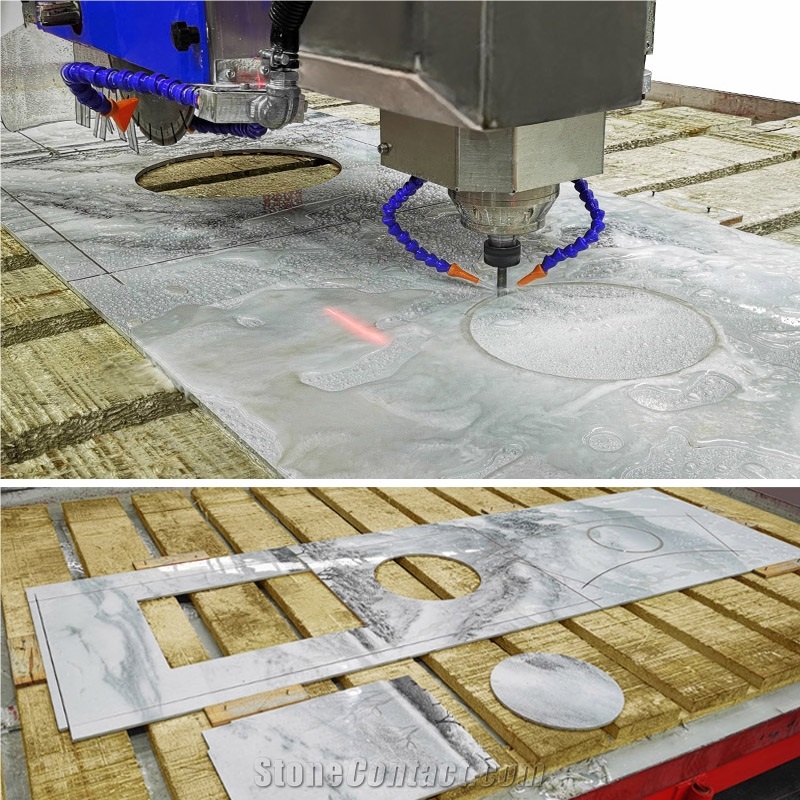

- Kitchen Countertops (sink cutouts, backsplash profiling)

- Bathroom Vanities (undermount sink cutting, water grooves)

- Architectural Cladding (wall panels, stair treads, window sills)

- Artistic Carving (3D reliefs, custom edge shaping)

Key Features:

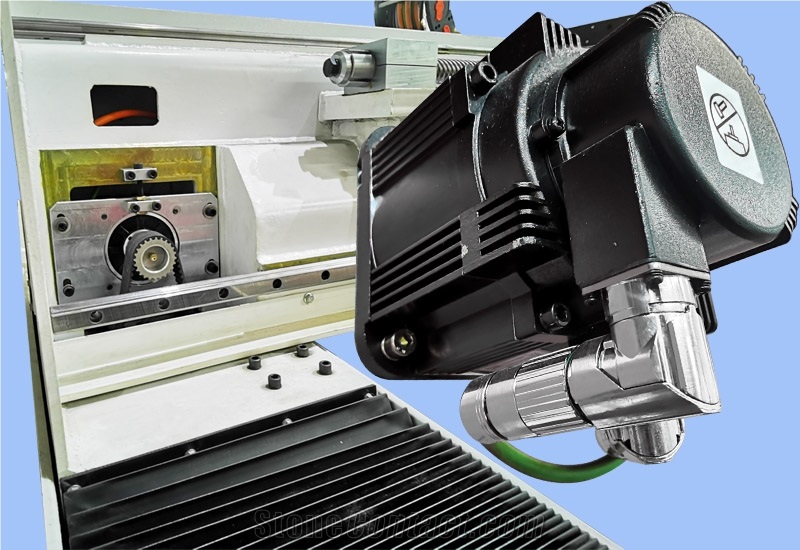

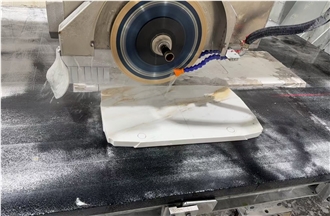

🔹 5-Axis Interpolation

- 0-90°tilting cuts for sinks & beveled edges

- C-axis 360°rotation for complex contours

🔹 Smart Nesting

- Canon EOS 1300D camera for manual defect marking

🔹 Heavy-Duty Construction

- Linear guides + ball screws (±0.01mm accuracy)

- 700kg heavier frame reduces vibration by 40%

🔹 Optional Upgrades

- 24K RPM spindle for precision milling

- Slab thickness detector for auto Z-axis adjustment

- Tool presetting unit for auto-compensation

- CE safety scanner (EN ISO 13849 certified)

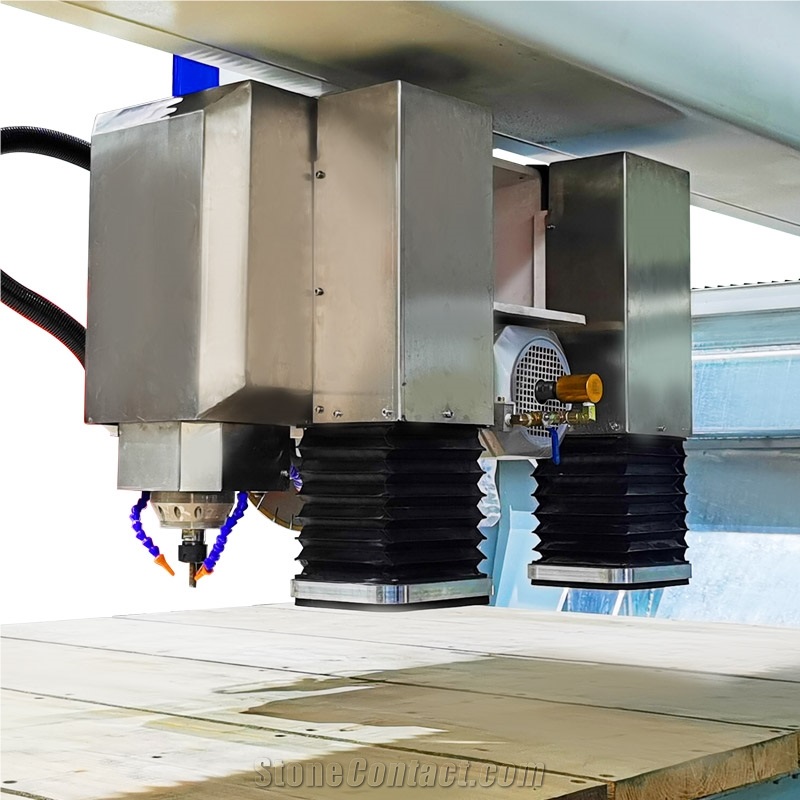

- Anti-vibration rubber table for breakage reduction

Applications:

✔ Countertops & Vanities

- Kitchen sink cutouts | Undermount sink supports | Water groove milling

✔ Architectural Stone

- Straight/curved cladding panels | Stair tread profiling | Window sill cutting

✔ Artistic Work

- 3D relief engraving | Custom edge chamfering | Curved surface joining

📌 Technical Specifications

| Parameter | HKNC-550 |

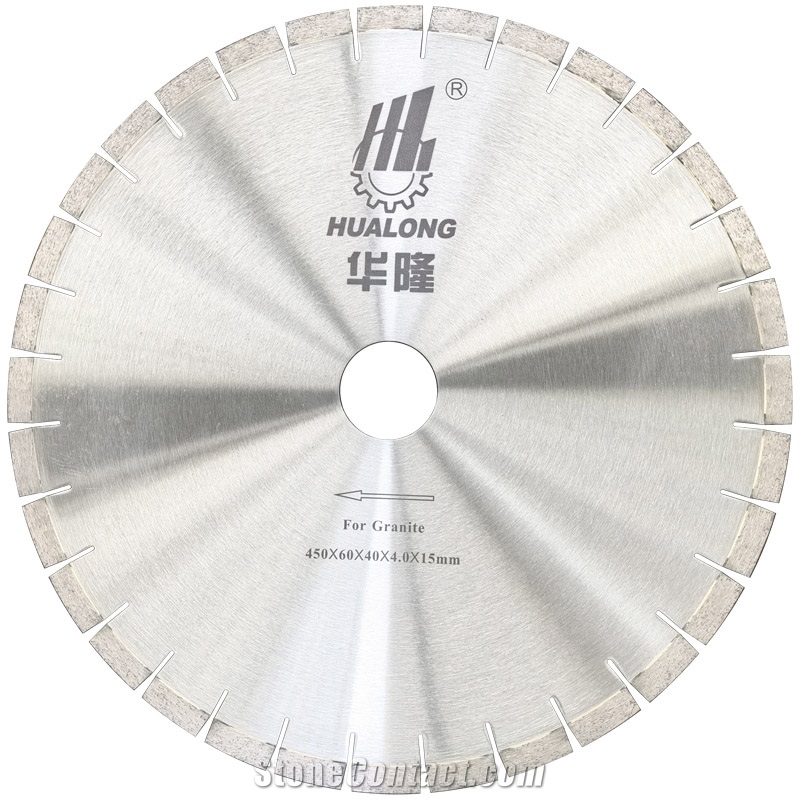

| Max.blade diameter | 550mm |

| Max.cutting thickness | 150mm |

| C-axis Rotation accuracy | ±0.005°(RV reducer) |

| X/Y/Z axis positioning accuracy | ±0.01mm |

| Gross weight | 6500kg |

🔥 Limited Offer: Free 24K RPM spindle upgrade for first 10 orders ($5,000 value)

📞 Contact Now: +86-182-0602-1758

Parameters |

Unit |

HKNC-550 |

Vertical cutting spindles motor power |

kw |

1 |

Max. cutting depth |

mm |

150 |

Tools holder head inclination(A axis blade rotation) |

° |

90 |

Dimensions of the work table(L×W) |

mm |

3500x2100 |

Cooling water requirement(1.5 bar min. pressure) |

L/min |

33.3 |

Disc diameter |

mm |

350-550 |

Worktable turn-over degree |

° |

85 |

Machine height |

mm |

3200 |

C axis blade rotation |

° |

360 |

Max.length of the cut slab |

mm |

3500 |

Machine length |

mm |

5900 |

Max.width of the cut slab |

mm |

2100 |

Machine width |

mm |

3680 |

Max. liftable weight with all the vacuum cups activated |

Kg |

200 |

Head motor power |

kw |

1.6 |

Disc motor power |

kw |

18.8 |

Head raising/lowering stroke(Z axis travel) |

mm |

350 |

Gross power |

kw |

33.7 |

Crossbeam motor power |

kw |

2.6 |

Hydraulic station motor power |

kw |

2.2 |

- Slab cutting handling

- 2D CAD tools

- Import 2D CAD files in DXF, DWG formats, etc.

- Geometric macros

- Automatic or manual nesting of shapes on slab

- Disk table management

- Calculation of optimized trajectories for the disk cutting

- Automatic rest machining to complete the cuts using a cut-drill/mill tool or a waterjet tool

- Movement of the slab pieces through the suction cups manipulator

- Acquisition and correction of the slab image through a camera

- Solid simulation with material removal and collisions control

- Management of processing reports

-

Double servomotors for Y-axis

-

Cannon camera

-

Blade presetting unit

¥Payment Required -

Retractable electro-spindle

¥Payment Required -

Ball screw & Linear guide

-

Vacuum lifter

-

Italian ESA CNC with 24" screen

-

RV reduction gear

-

Galvanization frame

-

Cabinet with cooling system

-

Ball screw and linear guide

-

Slab thikness detector

¥Payment Required

4 / 5 Very satisfied

Vis***

4/17/2025 12:11:24 PM

Related Products:

Fujian Province Hualong Machinery Co.,Ltd

Sales Manager

China

China

3YR

3YR

Tel:0086-18705943969

Contact supplier

Canada

2024

Canada

2024

Spain

2024

Spain

2024

Tina Chen

Tina Chen