5 AXIS CNC Bridge Cutting Machine

FOB Price:$45000-51000

Parameters |

Unit |

CNC 450-5 AI |

CNC 600-5 AI |

CNC 700-5 AI |

Approximate weight without table |

Kg |

5000 |

5000 |

5000 |

Machine height |

mm |

3600 |

3600 |

3600 |

Worktable turn-over degree |

° |

85 |

85 |

85 |

C axis blade rotation |

° |

0-360 |

0-360 |

0-360 |

Bridge transversal stroke(Y axis travel) |

mm |

2250 |

2250 |

2250 |

Machine width |

mm |

3400 |

3400 |

3400 |

Max. dimensions of the liftable piece |

mm |

300 |

500 |

500 |

Max.width of the cut slab |

mm |

2000 |

2000 |

2000 |

Machine length |

mm |

5800 |

5800 |

5800 |

Max. cutting depth |

mm |

180 |

180 |

230 |

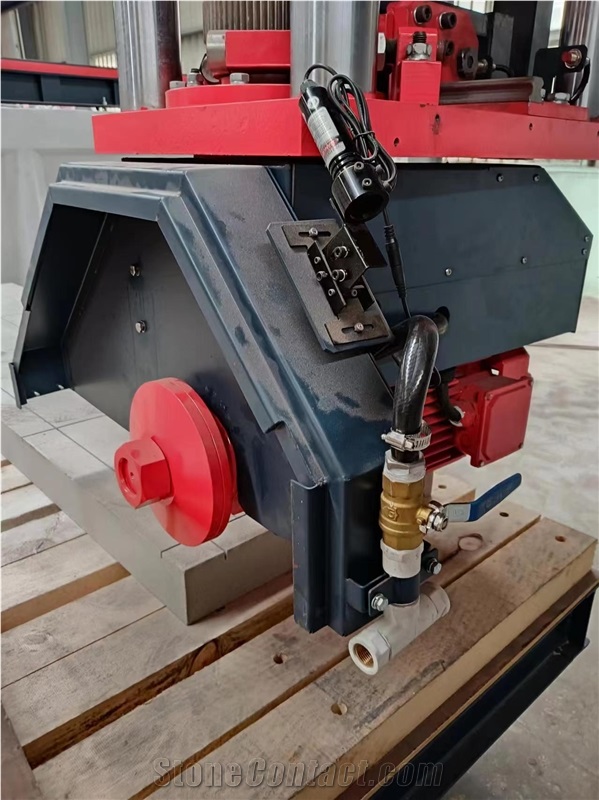

Cooling water requirement(1.5 bar min. pressure) |

m3/h |

3 |

3 |

3 |

Max. dimensions of the piece for “rodding” application |

mm |

450 |

600 |

700 |

Horizontal stroke(X axis travel) |

mm |

3300 |

3300 |

3300 |

Max.length of the cut slab |

mm |

3200 |

3200 |

3200 |

Average level of equivalent sound pressure |

dB |

60-80 |

60-80 |

60-80 |

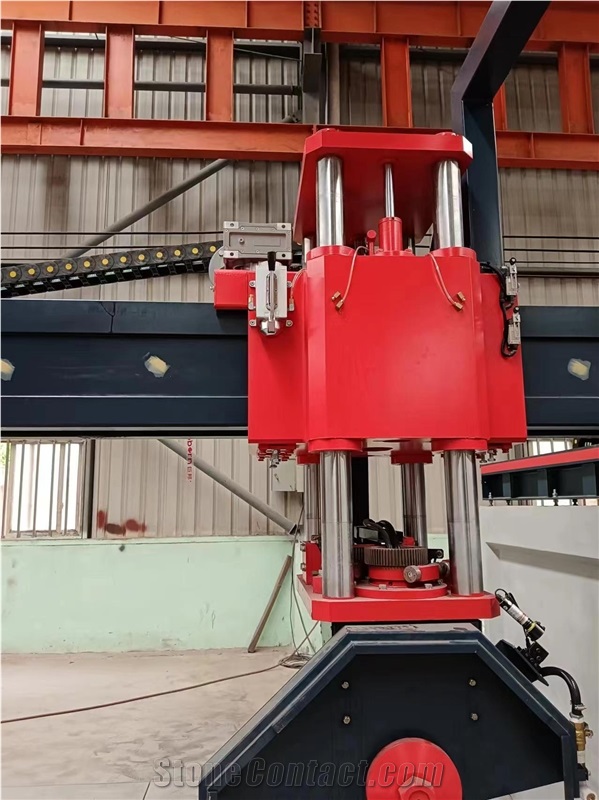

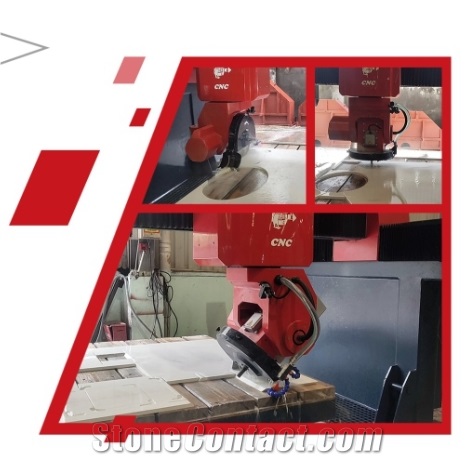

CNC450/600/700-5 AI five-axis CNC bridge cutting machine. This series adopts industrial computer and is equipped with Windows system, which can realize manual programming or PC programming and other programming methods to automatically complete processing operations. Cutting, grooving, countertop processing, special-shaped processing, etc.,

Standard camera function for visualization and easy operation. The tool setting function can measure the diameter of the saw blade in real-time and compensate for wear and tear,it could ensure makes the processing non stop.

The structure adopts an integral steel frame, which has been treated with stress relief in multiple processes, and has a stable structure, easy installation and high precision. The main motor adopts the spindle motor, which can be equipped with a milling cutter.

In terms of transmission, the XY axis adopts high-precision rack and pinion transmission and high-precision linear guide rail guidance. The Z axis is driven by a ball screw and guided by a high-precision linear guide. A-axis and C-axis all use precision robot reducer.

The whole machine has high positioning accuracy, repeated positioning accuracy, good cutting accuracy and high stability, and is especially suitable for the processing of high-value and large-sized granite, marble and slate.

1.5 Axis linkage control with CNC control system;

2.Easy to use interface with 17" color touch-screen;

3.The machine is equipped with an industrial computer, embedded touch screen, supports CAD file import;

4.The machine adopts integrated structure, the frame and beam are welded by high-quality carbon steel plate and profiles, solid and reliable, high stability;

5.The X-axis lateral movement adopts servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision helical rack and pinion drive;

6.Y-axis longitudinal movement adopts double servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision helical rack and pinion drive;

7.The Z-axis main machine lifting adopts servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision ball screw drive;

8.A-axis head tilt rotation 0-90° and C-axis head plane rotation 0-360° are driven by servo motor + precision robot RV reducer, supporting five-axis linkage, high dimensional precision and shape precision;

9.Working platform can tilt 85 degrees, easy for slabs loading;

10.Photo taking & tool setting function;

11.Milling cutter function;

12.Suction cup function(optional);

13.Thickness measurement function(optional);

No Reviews

Related Products:

FUJIAN JOBORN MACHINERY CO.,LTD.

China

China

4YR

4YR

Tel:0086-19396064994

Contact supplier

Jessica Hu

Jessica Hu