BRETON GENYA CNC monoblock bridge saw for marble, granite

FOB Price:

Type:

Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

Usage:

Granite, Marble, Artificial Stone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Delivery Details: FOB

Payment :

Supplier

Breton S.p.A.

Italy

Italy

Eatablished :Dec 31,1962

Main Product:

Stone Machines, Cutting Machine, Polising Machine, Wire Saw, Cnc Machines|

Machinery Function Features

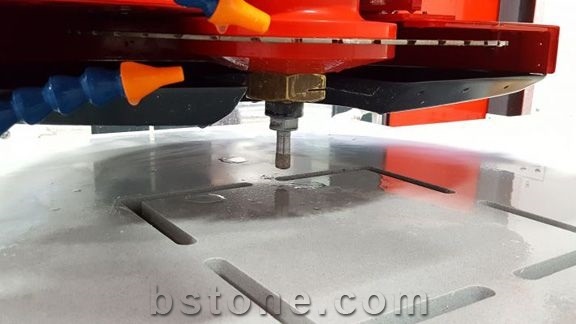

BRETON GENYA - CNC MONOBLOC BRIDGE SAW WITH ROTATING HEAD FOR MARBLE, GRANITE, ENGINEERED STONE AND CERAMIC

The very popular and widely available WORTHY machine has been restyled and upgraded with new technologies to create the new GENYA, which enters the market as the most advanced monobloc CNC sawing machine.

No foundation

The machine is simply secured to the floor.

Easy-to-use software

The machine’s software interface is easy to use and may be operated on different sophistication levels.

The “Easy” level allows the operator to rapidly and easily carry out all simple cutting operations using the colour touchscreen.

Through the “Advanced” level, the operator can program more complex cutting and shaping operations.

The control console is equipped with a joystick to easily move the several machining axes.

Cutting trajectory laser tracker

Automatic tilting disk between 0° and 90°

Inverter motor/spindle

1/2” gas connection for core drill attachment

Through-spindle water

Slab thickness probe for miter cuts with continuous automatic correction of the cutting measurements

Axis C Rotation ± 190°

Fixed camera to take a photo of the whole slab with a single snapshot

Pick-up unit with suction cups and optimization software with automatic nesting to optimize slab surface usage depending on work orders

Disk diameter electronic control

Tilting table

Work table covered with special rubber to ease ceramic material machining

Slab thickness probe automatically corrects cutting dimensions for the perfect 45° miter.

GENYA has a powerful and generous "CNC power unit" - the famous Siemens 840SL.

The control console can be positioned in the most convenient way for the operator and is equipped with a 15 “color touch screen, complete with joystick for intuitively moving the various work axes.

A mobile push-button panel facilitates the operations that must be carried out near the piece.

The user-friendly software works in Windows environment, allowing the importation of DXF files and structured DXFs containing technological information on the cuts, and giving the possibility to operate on two different levels:

• “Easy” level

• “Advanced” level

Technical Data

Parameters |

Unit |

BRETON GENYA |

Bridge transversal stroke(Y axis travel) |

mm |

2650 |

Machine length |

mm |

6160 |

Max. workable thickness(350mm dia. blade) |

mm |

50 |

Disc diameter |

mm |

350 min. to 600 max. |

Head raising/lowering stroke(Z axis travel) |

mm |

320 |

Machine height |

mm |

3930 |

Tools holder head inclination(A axis blade rotation) |

° |

0/+90 |

Max. revolutions of the spindle unit |

rpm |

min.:1000 to max.: 5000 |

Max.length of the cut slab |

mm |

3000 |

Dimensions of the work table(L×W) |

mm |

3800x2400 |

Vertical stroke speed (Z displacement speed) |

m/min |

10000 |

Max. workable thickness(with 600mm blade) |

mm |

180 |

Horizontal stroke(X axis travel) |

mm |

3800 |

Transversal stroke speed (Y displacement speed) |

m/min |

40000 |

Horizontal stroke speed(X axis displacement speed) |

m/min |

45000 |

Max.width of the cut slab |

mm |

1700 |

Number of vertical cutting spindles |

nr |

1 |

C axis blade rotation |

° |

380 |

Disc motor power |

kW |

13 |

Machine width |

mm |

4340 |

Approximate weight without table |

kg |

5900 |

Components

Consumables

Recommended CNC Bridge Cutting Machine Products

Reviews

No Reviews

BRETON GENYA CNC monoblock bridge saw for marble, granite

Mr.Stefano Titotto

Sales Manager

Italy

Italy

Tel:+39-423 7691

Contact supplier

Stefano Titotto

Stefano Titotto