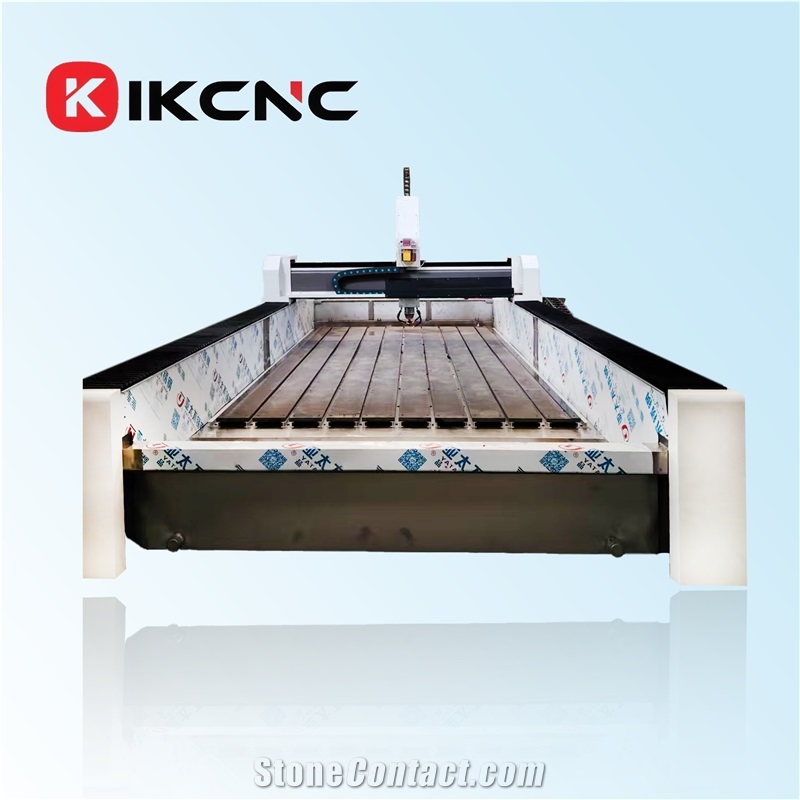

Stone CNC Router For Engraving CNC Engraver Carving Granite And Marble

FOB Price:$6600-7300

Functional characteristics.

Y axis unilateral double row 30 linear guide(total 4 guide), the structure and the operation are more stable.

1.5M grinding high precision rack, Japan Xinbao reducer transmission, fast speed, high processing accuracy.

Machine body with thick square pipe and double horizontal support structure, no deformation, bearing

significant.

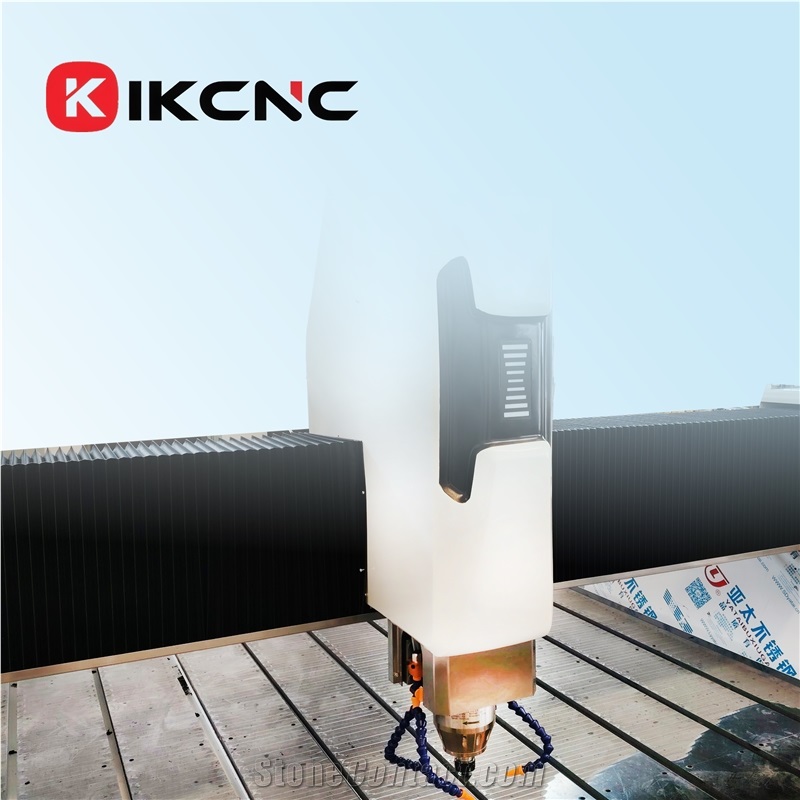

Three-axis high power, brand servo motor, Z-axis lock motor, long time work more stable.

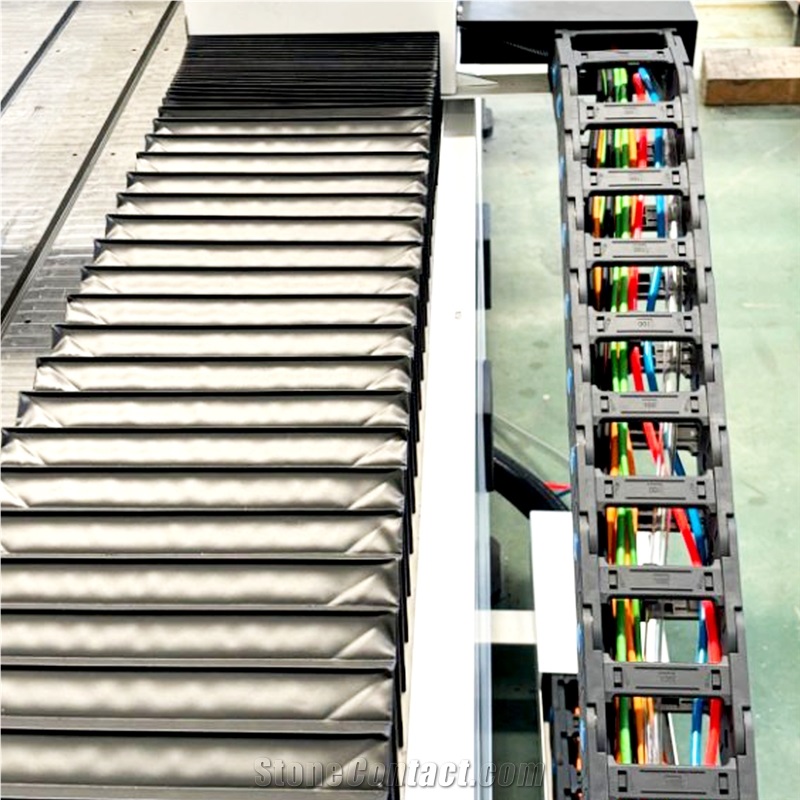

The cable of whole machine is high quality, low temperature resistance, high folding resistance and long servicelife.

Parameters |

Unit |

Ik-1325 |

Max. processing length |

mm |

1300 |

Control System |

Nc studio |

|

Total power |

kw |

11 |

Machine overall width |

mm |

3700 |

Approx. Weight |

T |

1.5 |

Main spindle speed |

r/min |

24000 |

Max. processing thickness |

mm |

400 |

Max. Processing Width |

mm |

2500 |

Machine overall length |

mm |

2500 |

Main spindle motor power |

kw |

7.5 |

NC Studio is a computer numerical control system primarily used to control various processing equipment, such as milling machines, lathes, laser cutting machines, and stone cutting-grinding all-in-one machines. Its working principle is based on computer technology, automatic control theory, and communication technology, aiming to convert digital processing instructions into actual actions of the equipment to achieve precise processing operations. The details are as follows:

Instruction Input and Parsing:

Multiple Input Methods: Operators can manually input processing instructions through the operation interface of NC Studio, or import G-code files generated by CAD/CAM software (such as UG, Mastercam, AutoCAD, etc.). These G-codes are a universal numerical control programming language that specifies key processing parameters in detail, including tool path, cutting speed, and feed rate.

Instruction Parsing Process: After the system reads the input instructions, its core processor decodes and calculates these instructions. For example, it parses coordinate values and motion instructions (such as linear interpolation G01, circular interpolation G02, etc.) in the G-code into specific motion information of each axis (X, Y, Z axes, etc.) of the equipment, clarifying the movement direction, distance, and speed of each axis.

Stone engraving machines use CNC systems to turn digital designs into stone carvings via coordinated tool movement.

They take G-code instructions (from CAD/CAM software) and convert them into signals for axis movement (X, Y, Z, and rotary A for 3D work). A high-speed spindle with diamond or carbide tools grinds the stone, adjusting speed and pressure based on stone hardness.

Axes work together: X/Y trace patterns, Z controls depth, and A rotates stone for curves. Sensors monitor tool position and stone stability, correcting deviations in real-time.

Cooling and dust removal systems run alongside, while advanced models auto-change tools for relief, line, or 3D carving. This setup ensures precise, efficient stone engraving.

4.7 / 5 Very satisfied

JEN***

9/11/2025 9:37:48 AM

raf***

8/20/2025 3:10:21 PM

luy***

8/14/2025 11:46:54 AM

Related Products:

JINAN IKCNC TECHNOLOGY CO.,LTD

China

China

1YR

1YR

Tel:86-15615410983

Contact supplier