4 Axis CNC Bridge Saw Four-Axis Cutting Machine IK-3220-400

FOB Price:$13000-16600

Four-axis bridge cuting machine is specially designed for stone special-shaped cutting, and precision cutting of countertop, it can process a variety of complex special-shaped, Simple operation, high intelligent automation, users only need to enter a few simple data, you can quickly finish the cutting of various size specifications of the table and edge strips, greatly saving labor, but also put an end to dust pollution, improve work efficiency and plate processing accuracy, it supports CAD graphics import, measuringinstrument.

Introduction To Functions:

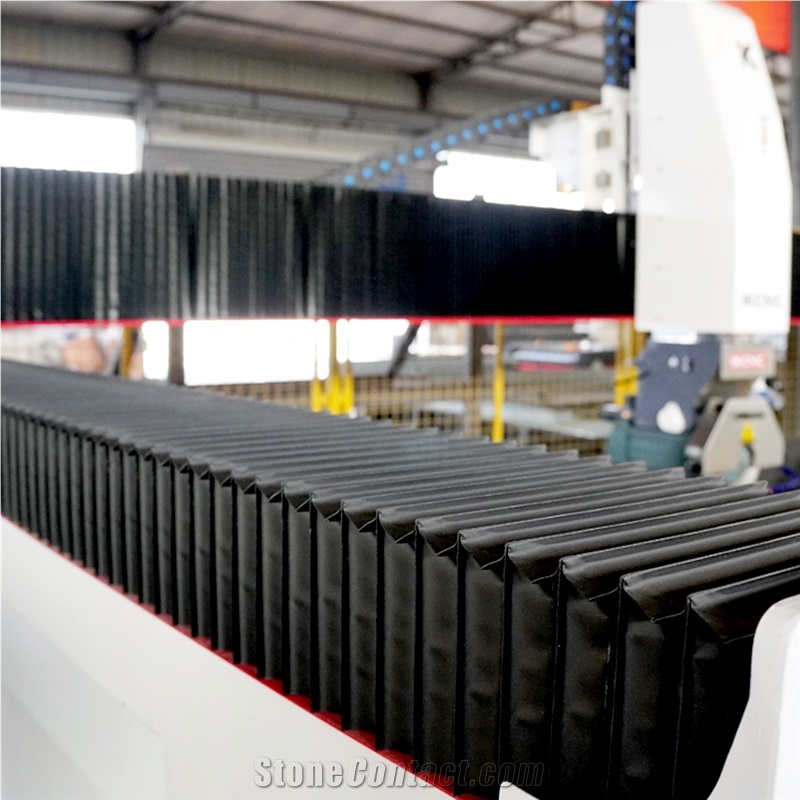

1. Machine body with solid gantry girder, quenching heat treatment, guide rai, rack hole, all imported five-sided milling machine, fine milling, drilling, the precision is very high.

2.The paint of the whole machine, after many times of grinding, anti-rust treatment, many times of painting, effectively resist the corrosion of ground water, paint is more durable and less prone to peeling.

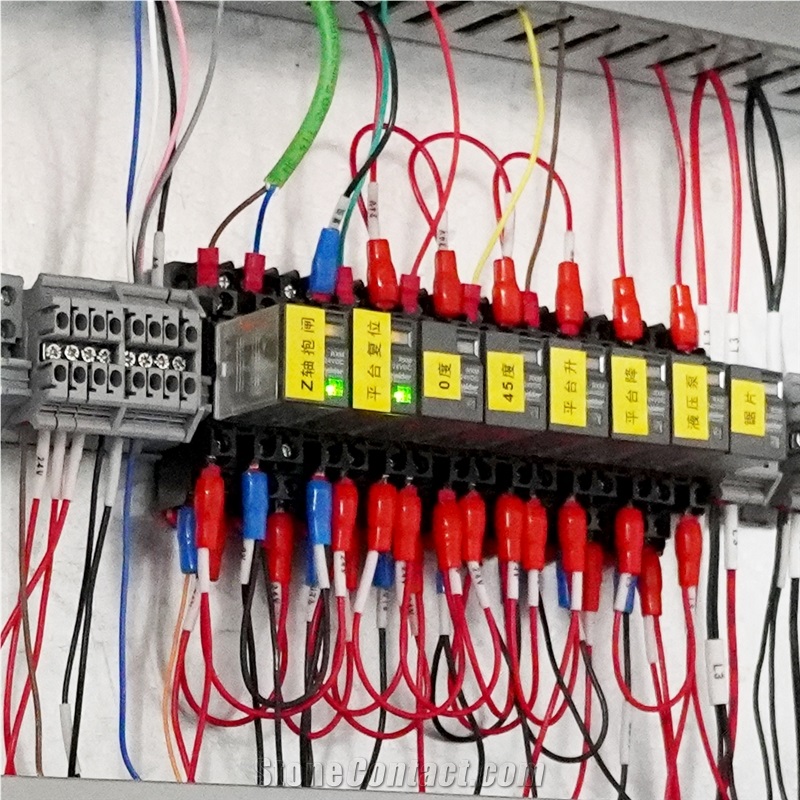

3.The cable of whole machine use CE standard, low temperature resistance, high folding resistance and long service life.

4. Electrical cabinet wiring is in accordance with the export of Europe and the United States international standard, assembly, anti-interference, all electrical parts are genuine brand.

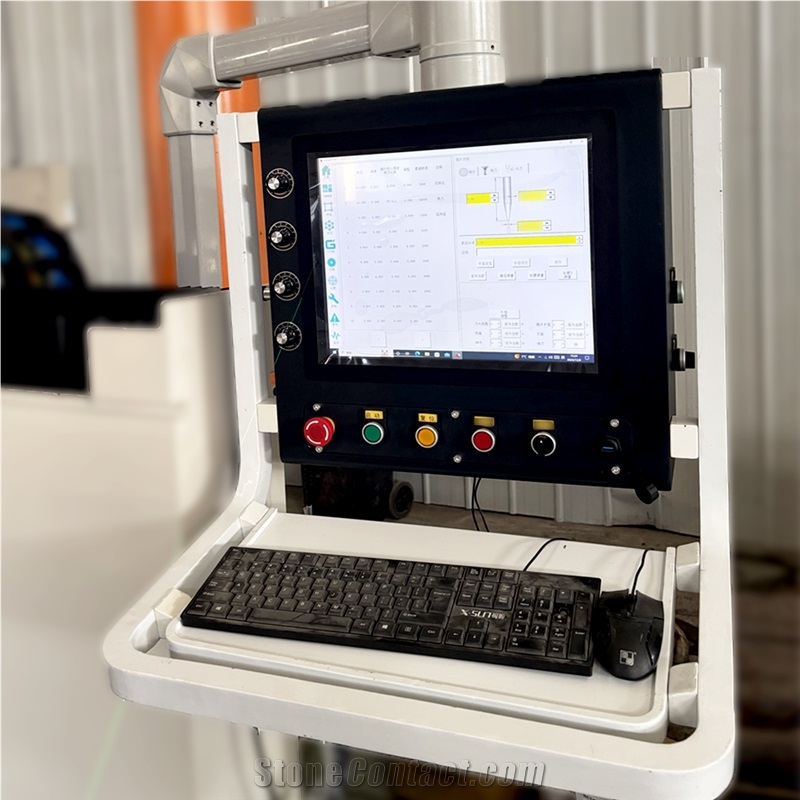

5. Independently developed CNc system, user-friendly, simple operation, with multiple functions, and support free upgrade later.

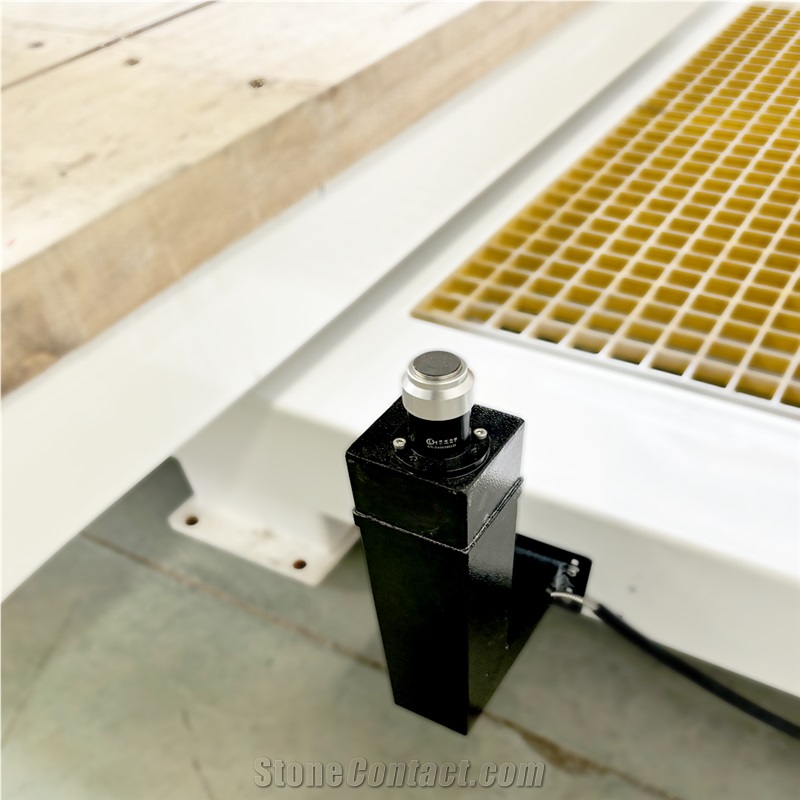

6. 45 degrees miter, 85 degrees flip platform, using hydraulic cylinder control, stable and accurate.

7. Included computer with touch screen support, both mouse and keyboard can control, with wireless controller.

Parameters |

Unit |

IK-3220-400 |

Machine height |

mm |

2900 |

Max. workable thickness |

cm |

7 |

Horizontal stroke speed(X axis displacement speed) |

m/min |

20 |

Approximate weight without table |

T |

4.5 |

Dimensions of the work table(L×W) |

mm |

3200*2000 |

Worktable turn-over degree |

° |

45 |

Installed electrical power |

kw |

18.5 |

Z-axis working travel vertical cutting spindles |

mm |

400 |

Machine width |

mm |

3300 |

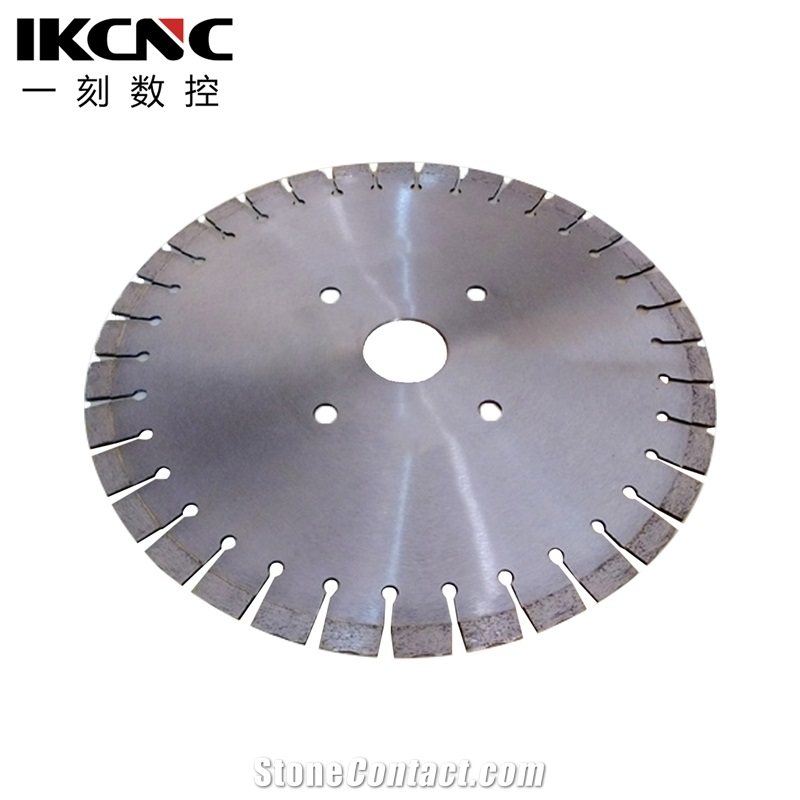

Disc diameter |

mm |

230 |

Tools holder head inclination(A axis blade rotation) |

° |

45 |

Max.length of the cut slab |

mm |

3200 |

Air consumption |

m3/h |

20 |

Cooling water requirement(1.5 bar min. pressure) |

m3/h |

2 |

Disc motor power |

kw |

1.5 |

Horizontal stroke(X axis travel) |

mm |

3200 |

Max. cutting depth |

mm |

7 |

Worktable Weight |

T |

4.5 |

Bridge transversal stroke(Y axis travel) |

mm |

2000 |

Number of vertical cutting spindles |

pcs |

1 |

Max.width of the cut slab |

mm |

2000 |

C axis blade rotation |

° |

360 |

Crossbeam motor power |

kw |

1.5 |

Head raising/lowering stroke(Z axis travel) |

mm |

400 |

Machine length |

mm |

5700 |

Head motor power |

kw |

18.5 |

Max. revolutions of the spindle unit |

r/min |

6000 |

Vertical stroke speed (Z displacement speed) |

m/min |

20 |

Hydraulic station motor power |

kw |

2.2 |

The system: CUTCAM

System function: Includes photo, intelligent layout, automatic adsorptionfunction.

Features: efficient andconvenient,save time andlabor

3D copying features: All kinds of lines are generated directly in the software, Simple and intuitive, no programming required

Custom function: Various sizes can be customized according to customer needs, and complex graphics can be cut by entering simple parameters. No need to import CAD drawing, simple and convenient, greatlyimprove production efficiency.

The 4-axis stone bridge cutting machine operates through the coordinated movement of the X, Y, and Z linear axes along with the A-axis rotation, driving the saw blade for precise stone cutting. Operators set cutting dimensions, angles, and paths through the CNC system, allowing the machine to automatically perform straight cuts, angle cuts, chamfering, and various complex shapes. It is widely used for cutting and profiling marble, granite, quartz, and other stone slabs, offering high precision, efficiency, and a high degree of automation.

4.5 / 5 Very satisfied

sha***

8/30/2025 4:43:03 AM

Gre***

7/21/2025 8:32:23 PM

Pin***

7/15/2025 8:17:07 PM

Mik***

7/13/2025 4:45:24 AM

Related Products:

JINAN IKCNC TECHNOLOGY CO.,LTD

China

China

1YR

1YR

Tel:86-15615410983

Contact supplier