6.3Mm 56 Wires Multi Wire Saw Machine For Stone Slabs Cutting

FOB Price:$300000-500000

Type:

Stone Factory MachinesStone Block Cutting MachinesMulti Wire Saw Machine

Usage:

Granite, Marble, Limestone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Lead Time:

120

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Port:

shenzhen- China

Delivery Details: FOB,CFR,CIF,EXW,FCA

Payment :

More

Machinery Function Features

Toolstar multi wire saw machine

1,SCHNEIDER(French)PLC+touch screen,Stable Functions,smooth operation.

2,Stable triangle structure designed by Toolstar R&D center(ltaly),Advanced technologies ensuring Toolstar to achieve industry-leading company

3,NSK(Japan) bearings,With self-lubricating high-precision wheel group,the lifespan of bearings exceeding 10000 hours.

4,China Biggest Manufacturer of Diamond

5,YASKAWA(Japan)Inverter,Harmonics resilience, strong anti-interference ability,reliable performance.

6,German Well-known Steel Cable Brand

Technical Data

Parameters |

Unit |

T-Rex MWSXB with 7.3mm Diameter Wires |

T-Rex MWSXN with 6.3mm Diameter Wires |

T-Rex MWSXS with 4.3mm-4.8mm Diameter Wires |

Machine length (L) |

mm |

11200 |

11200 |

11200 |

Max. Cutting width |

mm |

600-2100 |

600-2100 |

1600-2100 |

Diamond wires speed |

m/s |

0~35 |

0~35 |

0~35 |

Machine width (W) |

mm |

2600-7400 |

4500-7400 |

4500-7400 |

Wire pitch for sawing 20mm thick. |

mm |

28.5 |

27.9 |

24.8 |

Installed electrical power |

kw |

57-300 |

110-300 |

220-300 |

Max. Number of wires for sawing 30mm thick. |

nr |

76 |

76 |

88 |

Machine height (H) |

mm |

6500 |

6500 |

6500 |

Diamond bead diameter |

mm |

7.3 |

6.3 |

4.3-4.8 |

Diamond wire length |

mm |

21.52 |

21.52±0.02 |

21.52 |

Worktable max. rotate angle |

° |

not allowed |

not allowed |

not allowed |

Dim. Trolley Size/Worktable size |

mm |

2000*2500-2500*3200 |

2500*3200 |

2500*3200 |

Pitch groove wire driving |

mm |

2450 |

2450 |

2450 |

Worktable load capacity |

T |

40-80 |

80 |

62 |

Max. Cutting length |

mm |

3400 |

3400 |

3400 |

Max. individual diamond wire tension |

Kg |

220-260 |

180-220 |

160-200 |

Wire pitch for sawing 30mm thick. |

mm |

38 |

37.2 |

none |

Fast lowering unit power |

kw |

37 |

132 |

200 |

Production efficiency 20mm thick. |

m2/h |

it depends,contact us to know more details |

it depends,contact us to know more details |

it depends,contact us to know more details |

Slabs nominal thickness |

mm |

20/30/40/50/60/70/80/90/100 |

20/30 |

18 |

Max. Cutting height |

mm |

2100 |

2100 |

2100 |

Max. Number of wires for sawing 20mm thick. |

nr |

76 |

76 |

88 |

Wires set width |

mm |

7.3 |

6.3 |

4.3-4.8 |

Voltage/Frequency |

V/Hz |

it depends on which country |

it depends on which country |

it depends on which country |

Cooling water(min. required pressure 3.5 bar) |

L/min |

150-1500 |

1000-1500 |

1500 |

Main motor power |

kw |

37-280 |

90-280 |

200-280 |

Approximative Weight |

T |

25-62 |

50-62 |

50-62 |

Output number of slabs 30mm per linear mt. |

nr |

it depends |

it depends |

it depends |

Output number of slabs 20mm per linear mt. |

nr |

it depends |

it depends |

it depends |

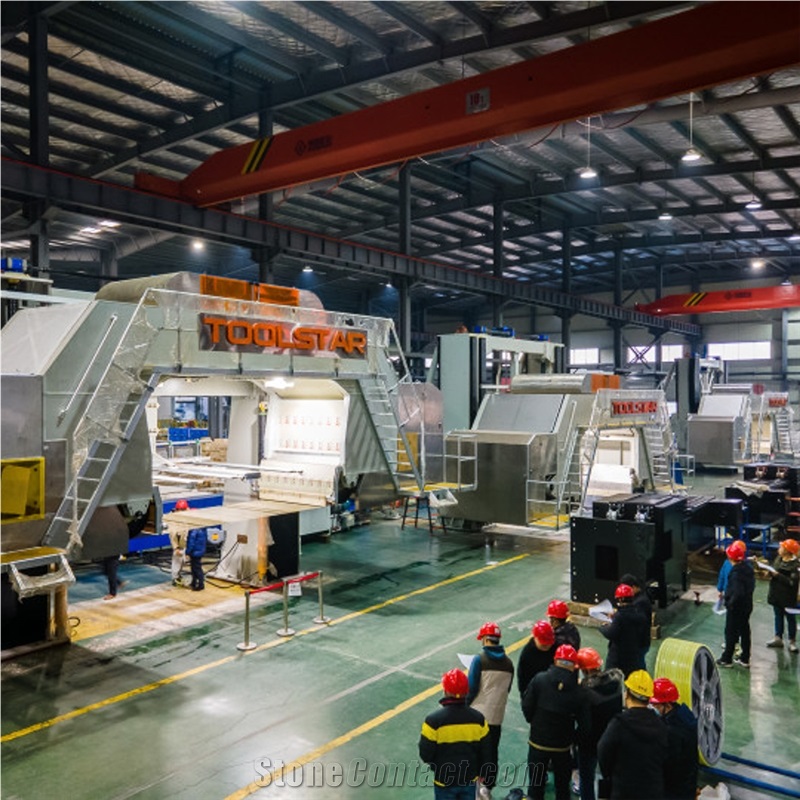

Work Example

- Independent hydraulic tensioning system is applied to obtain the same tension foreach wire. This will ensure that all the wires can get the best cutting result.

- The main motor and feeding motor are powered by inverters to obtain the suitablewire speed and feeding speed according to the type of granite or marbl

- Detector switches are used to monitor the wire breakage. The machine will stopautomatically while any wire is broken.

- There is safety detector switch on the up/down screw. It will alarm automatically ifthe screw is worn out.

- All the flywheel liner is independent and can be replaced separately if one part isworn out. The guide wheel rubber can reach 2000hours.

- It is variable thickness cutting by changing the wire position in the different groove ofliners.

- Convenient climbing ladder and platform as well as sliding doors of the top and bothside protective covers makes wires installation and machine maintenance easier.

- Adopt multi method to operate machine with touchscreen + PLC + remote control. It displays the critical parameters, including the actual working current, wire speed, feeding speed, working hours etc. The operating parameters can be adjusted any time according to different requirement with easy operation and high reliability

Components

Customer Case

Video

Install Video

Operation Video

Screen.PrimaryScreen.Bounds.Height

Recommended Multi Wire Saw Machine Products

Reviews

4 / 5 Very satisfied

t

Vic***

12/13/2024 11:42:32 AM

Related Products:

Multi Wire Saw Machine

Machinery

Stone Factory Machines

Stone Block Cutting Machines

Diamond Wire Machine

Multi Wire Cutting Machine

Wire Saw Block Cutting Machine

Granite Multi Wire Saw Machine

Marble Multi Wire Saw Machine

Limestone Multi Wire Saw Machine

Basalt Multi Wire Saw Machine

Quartzite Multi Wire Saw Machine

Sandstone Multi Wire Saw Machine

Travertine Multi Wire Saw Machine

Toolstar Machines

6.3Mm 56 Wires Multi Wire Saw Machine For Stone Slabs Cutting

CHANGSHA TOOLSTAR MACHINERY MANUFACTURING CO., LTD

Mr.Rex Shen

Sales Manager

China

China

3YR

3YR

Tel:86-18890060093

Contact supplier

India

India

Australia

Australia

Rex Shen

Rex Shen