If you need our help, we will be glad to help you until you find your products.

Skype: StoneContact.com

WhatsApp/Wechat: +86-17689946988

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

FOB Price:$10500-13500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Quartzite, Sandstone, Travertine

Machinery Function Features:

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

FOB Price:$12800-13600

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Sandstone

Machinery Function Features:

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

FOB Price:$20999-23999

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

FOB Price:$22000-25000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

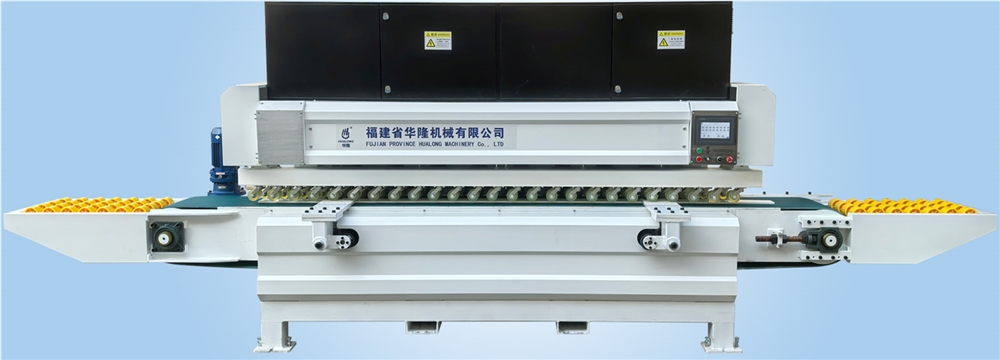

HLCM-8E80 Automatic Shaped Edge Grinding Machine

Intelligent Stone Edge Profiling Solution for Industrial Efficiency

Product Overview

The HLCM-8E80 is a fully automated, CNC-controlled stone edge grinding machine designed for precision shaping and polishing of marble, granite, quartz, and large-format slabs. Engineered with an 8-head sequential processing system (2 shaping + 6 polishing) and conveyor belt automation, it delivers 20% faster production speeds than conventional machines while maintaining micron-level accuracy. Ideal for fabricating kitchen countertops, stair treads, windowsills, and custom architectural elements, this machine combines zero-downtime operation with plug-and-play versatility – empowering stone workshops to handle complex edge profiles (ogee, bullnose, pencil, etc.) at scale without skilled labor dependency.

Why HLCM-8E8O Dominates the Market?

✅ Unmatched Throughput

- 20% Faster Cycle Time: Continuous conveyor processing eliminates manual loading gaps.

- 8-Head Synergy: 2 shaping heads pre-profile edges → 6 polishing heads achieve mirror finishes in one pass.

✅ Precision Redefined

- Auto Wheel Compensation: Real-time abrasive wear adjustment ensures ±0.2mm tolerance.

- Quick tool calibration via pneumatic lifting device (no technician required).

✅ Cost-Slashing Innovation

- 5-Min Wheel Swap: Magnetic locking system reduces changeover time by 70%.

- 50% Labor Saving: Fully automated operation supports 24/7 production with 1-2 operators.

✅ Future-Proof Reliability

- Smart Diagnostics: IoT-enabled alerts for low material, motor overload, or belt misalignment.

- Global Compliance: CE, and ISO 9001 certified.

Technical Specifications

- Workpiece Width: 100-2000mm | Max. Thickness: 80mm

- Motor Power: 36kW | Voltage: 380V/50Hz (Customizable)

- Control System: Industrial-grade CNC with multi-language interface

- Tool Stations: 8 independent heads (2×4kW shaping + 6×4kW polishing)

Who Benefits Most?

◼ High-volume countertop manufacturers

◼ Stone exporters targeting EU/US premium markets

◼ Contractors bidding on luxury hotel/condo projects

◼ Workshops upgrading to Industry 4.0 standards

Act Now & Gain More!

🔥 Free On-Site Installation (First 10 Orders)

🔥 Lifetime Software Updates

🔥 2-Year Warranty on Core Components

Claim Your Competitive Edge!

📞 Call +86 182-0602-1758 for Instant Pricing & Free ROI Analysis

📧 Email: [email protected]

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

FOB Price:$11000-17000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Artificial Stone, Quartzite, Travertine

Machinery Function Features:

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$15000-18000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$15000-20000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$10500-11000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Sandstone

Machinery Function Features:

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$5000-5200

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Auto-Follow Round Table Edge Grinder

Compact & Intelligent Solution for Luxury Stone Furniture

A game-changing edge grinder specializing in luxury round tables & irregular countertops. With satellite rotary speed control + constant-pressure system, it masters curved edge processing of marble, sintered stone, and exotic slabs. 60% faster ROI in 5㎡ workspace – the ultimate flexible upgrade for SMEs.

Core Advantages

🔥 【Auto-Follow Precision】

Real-time edge tracking | Single-pass shaping for round/oval/wave edges | ±0.3mm accuracy

🔥 【Satellite Speed Master】

0-6rpm stepless speed control | On-the-fly adjustment | Perfect for intricate curves

🔥 【Dual-Mode Flexibility 】

Full-auto for round tables (Φ550-2000mm) | Semi-auto with cylinder for custom shapes

🔥 【Space-Saving Hero 】

5㎡ footprint | 10-min operator training | 40% energy saving

🔥 【Constant-Pressure Genius】

Auto force stabilization | 90% edge smoothness improvement

🔥 【Modular Upgrade】

Add-on mini turntable (Φ110-500mm) | Bevel edge grinding kit

Technical Specifications

*Processing Range: Φ550-2000mm round tables | Thickness ≤80mm

*Turntable Speed: 0-15rpm stepless

*Motor Power: 5.5kW servo

*Air Pressure: 0.6-0.8MPa

*Materials: Marble/Granite/Exotic Stone/Sintered Slabs

Who Needs This?

◼ Luxury hotel furniture suppliers

◼ High-end custom furniture ateliers

◼ Artistic slab processors

◼ Stone export traders

Limited Offer!

🎯 First 10 orders: FREE $1500 bevel grinding kit

🎯 Lifetime remote support

🎯 1st year cost-price spare parts

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$3600-3900

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Quartzite, Sandstone, Travertine

Machinery Function Features:

7YR

7YR

China

China

XIAMEN EASTERN PEGASUS CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$16000-18000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$20000-22000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$15000-25000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$20000-22000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Quartzite

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$10000-11000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Artificial Stone, Basalt, Sandstone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$15500-17500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$17250-18100

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Quartzite, Travertine

Machinery Function Features:

7YR

7YR

China

China

XIAMEN EASTERN PEGASUS CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$48888-51200

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Sandstone, Travertine

Machinery Function Features:

7YR

7YR

China

China

XIAMEN EASTERN PEGASUS CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$16000-24500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$7500-8000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$7000-7500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$8600-9000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$2100-2250

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$2100-2900

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$17600-18900

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$41000-43000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$3300-3700

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$25500-26000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

This machine is mainly used for processing thick and polished strips of narrow strips, narrow strips, roadside stone, etc. The machine adopts micro-computer automatic control, the operation is simple and convenient, the whole processing flow adopts integrated processing, the front section is thick and the head is responsible for the thickness, and the rear section is multi-grinding and grinding, which is the ideal equipment for processing strip-like stone.

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$12000-13000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$17000-20000

Warranty: 12 Months

Usage: Granite, Marble

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$10000-10000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Artificial Stone, Basalt, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$10000-10000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$2000-2200

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$10000-10000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$14500-15500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$16000-17000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$35000-55000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Conveying Structure: 400mm extra wide belt + high elasticity silicone pressure beam

Thickness Adjustment: Automatic adjustment

Direction Of Operation: Facing operator panel, the product comes from right to left

Main Drive: Adopt 3kw frequency conversion speed control motor reducer

Machine Frame: Adoption of steel structure welding and annealing treatment process

China

China

SHANGHAI CHEERSURE INTERNATIONAL TRADING COMPANY

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$5000-5200

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Auto-Follow Round Table Edge Grinder

Compact & Intelligent Solution for Luxury Stone Furniture

A game-changing edge grinder specializing in luxury round tables & irregular countertops. With satellite rotary speed control + constant-pressure system, it masters curved edge processing of marble, sintered stone, and exotic slabs. 60% faster ROI in 5㎡ workspace – the ultimate flexible upgrade for SMEs.

Core Advantages

🔥 【Auto-Follow Precision】

Real-time edge tracking | Single-pass shaping for round/oval/wave edges | ±0.3mm accuracy

🔥 【Satellite Speed Master】

0-6rpm stepless speed control | On-the-fly adjustment | Perfect for intricate curves

🔥 【Dual-Mode Flexibility 】

Full-auto for round tables (Φ550-2000mm) | Semi-auto with cylinder for custom shapes

🔥 【Space-Saving Hero 】

5㎡ footprint | 10-min operator training | 40% energy saving

🔥 【Constant-Pressure Genius】

Auto force stabilization | 90% edge smoothness improvement

🔥 【Modular Upgrade】

Add-on mini turntable (Φ110-500mm) | Bevel edge grinding kit

Technical Specifications

*Processing Range: Φ550-2000mm round tables | Thickness ≤80mm

*Turntable Speed: 0-15rpm stepless

*Motor Power: 5.5kW servo

*Air Pressure: 0.6-0.8MPa

*Materials: Marble/Granite/Exotic Stone/Sintered Slabs

Who Needs This?

◼ Luxury hotel furniture suppliers

◼ High-end custom furniture ateliers

◼ Artistic slab processors

◼ Stone export traders

Limited Offer!

🎯 First 10 orders: FREE $1500 bevel grinding kit

🎯 Lifetime remote support

🎯 1st year cost-price spare parts

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$16000-24500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Have a Question? Ask our expert

Tell Suppliers what you want to buy

Submitted successfully, thank you!