If you need our help, we will be glad to help you until you find your products.

Skype: StoneContact.com

WhatsApp/Wechat: +86-17689946988

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

FOB Price:$11000-20000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Type: Stone Factory MachinesStone Factory Cleaning EquipmentsWater Treatment Equipment

FOB Price:$5000-888888888

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

China

China

Quanzhou Nanxing Machinery Manufacturing Co., Ltd

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling Machines

FOB Price:$49990-54990

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Quartzite, Sandstone

Machinery Function Features:

China

China

Shandong WAMI CNC Technology Co.,Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Tile Cutting MachinesHydraulic Stone Splitting Machine

FOB Price:$16200-16700

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

FOB Price:$4300-5800

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Travertine

Machinery Function Features:

CNC Wire saw machine is an automatic profiling machine, designed for cutting complex shapes.such as solid columns, hollow columns, large stone lines and English letters, etc.

Type: Stone Factory MachinesStone Finishing, Profiling MachinesChamfering,Beveling Machine

$15500-25500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Quartzite

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$25000-40000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

9YR

9YR

China

China

Xiamen Qicheng Superhard Material Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesStone Carving,Engraving Machine

$8000-8150

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Functional characteristics.

Y axis unilateral double row 30 linear guide(total 4 guide), the structure and the operation are more stable.

1.5M grinding high precision rack, Japan Xinbao reducer transmission, fast speed, high processing accuracy.

Machine body with thick square pipe and double horizontal support structure, no deformation, bearing

significant.

Three-axis high power, brand servo motor, Z-axis lock motor, long time work more stable.

The cable of whole machine is high quality, low temperature resistance, high folding resistance and long servicelife.

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesStone Carving,Engraving Machine

$6000-9000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Tile Cutting MachinesStrip Cutting,Edge Trimming Machine

$7000-7900

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesChamfering,Beveling Machine

$15500-25500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

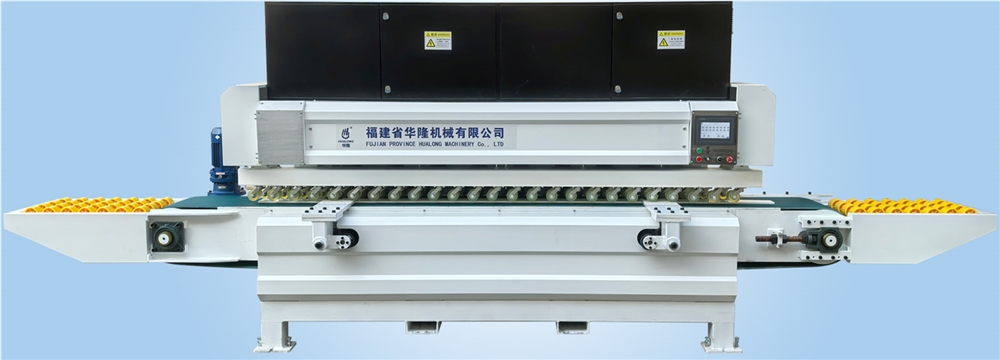

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$22000-25000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

HLCM-8E80 Automatic Shaped Edge Grinding Machine

Intelligent Stone Edge Profiling Solution for Industrial Efficiency

Product Overview

The HLCM-8E80 is a fully automated, CNC-controlled stone edge grinding machine designed for precision shaping and polishing of marble, granite, quartz, and large-format slabs. Engineered with an 8-head sequential processing system (2 shaping + 6 polishing) and conveyor belt automation, it delivers 20% faster production speeds than conventional machines while maintaining micron-level accuracy. Ideal for fabricating kitchen countertops, stair treads, windowsills, and custom architectural elements, this machine combines zero-downtime operation with plug-and-play versatility – empowering stone workshops to handle complex edge profiles (ogee, bullnose, pencil, etc.) at scale without skilled labor dependency.

Why HLCM-8E8O Dominates the Market?

✅ Unmatched Throughput

- 20% Faster Cycle Time: Continuous conveyor processing eliminates manual loading gaps.

- 8-Head Synergy: 2 shaping heads pre-profile edges → 6 polishing heads achieve mirror finishes in one pass.

✅ Precision Redefined

- Auto Wheel Compensation: Real-time abrasive wear adjustment ensures ±0.2mm tolerance.

- Quick tool calibration via pneumatic lifting device (no technician required).

✅ Cost-Slashing Innovation

- 5-Min Wheel Swap: Magnetic locking system reduces changeover time by 70%.

- 50% Labor Saving: Fully automated operation supports 24/7 production with 1-2 operators.

✅ Future-Proof Reliability

- Smart Diagnostics: IoT-enabled alerts for low material, motor overload, or belt misalignment.

- Global Compliance: CE, and ISO 9001 certified.

Technical Specifications

- Workpiece Width: 100-2000mm | Max. Thickness: 80mm

- Motor Power: 36kW | Voltage: 380V/50Hz (Customizable)

- Control System: Industrial-grade CNC with multi-language interface

- Tool Stations: 8 independent heads (2×4kW shaping + 6×4kW polishing)

Who Benefits Most?

◼ High-volume countertop manufacturers

◼ Stone exporters targeting EU/US premium markets

◼ Contractors bidding on luxury hotel/condo projects

◼ Workshops upgrading to Industry 4.0 standards

Act Now & Gain More!

🔥 Free On-Site Installation (First 10 Orders)

🔥 Lifetime Software Updates

🔥 2-Year Warranty on Core Components

Claim Your Competitive Edge!

📞 Call +86 182-0602-1758 for Instant Pricing & Free ROI Analysis

📧 Email: [email protected]

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Handling, Loading MachinesJib Arm/U Type Container Loader

$403-465

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone

Machinery Function Features:

2YR

2YR

China

China

XIAMEN SPEEDONE INDUSTRY CO., LTD

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

$11000-17000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Artificial Stone, Quartzite, Travertine

Machinery Function Features:

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Sandstone

Machinery Function Features:

8YR

8YR

Italy

Italy

Sassomeccanica S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Tile Cutting MachinesHydraulic Stone Splitting Machine

$11000-13000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

This stone splitting machine is designed with hydraulic drive to split square column stone into blocks cubes or blocks with rustic look. It is an efficient machine for producing cubic paving stones. Main Features 1.Open frame machine model for easy maintenance 2.Made of sturdy cast iron and high-quality components to ensure stability while working. 3.Rapid lifting motion greatly improves work efficiency. 4.Heat treated and hardened high carbon steel chisels produce superior cracks every time.

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesGiant Disc Saw Machine

$30000-50000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Sandstone, Travertine

Machinery Function Features:

9YR

9YR

China

China

Xiamen Qicheng Superhard Material Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Surface Processing Machines Slab Polishing Line Machine

$36000-49000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesColumn, Arc Slab Cutting Machine

$27000-32000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

APM-350-2000,Arc Slab Polishing Machine fix the arc slab by vacuum sucker, replaced conventional clamping fixing on both sides, solved the deviation of the squareness and inclination which were generated by the steps trimming-grinding, at the meanwhile, clear the customer's concerns about arc slab edge & angle damage. Machine adopt linear guides, multi grinding head and PLC system. it has a high-precision, high efficiency, easy operation and others, it is the ideal equipment for arc slab polishing.

1YR

1YR

China

China

XIAMEN XIANDA TRADING CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Surface Processing Machines Water Blast Machine

$5100-5300

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Sandstone, Travertine

Machinery Function Features:

1YR

1YR

China

China

China Team Electric Co.,Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Handling, Loading MachinesJib Arm/U Type Container Loader

€13494-13494

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone

Machinery Function Features:

1YR

1YR

Viet Nam

Viet Nam

AARDWOLF INDUSTRIES

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesMulti Wire Saw Machine

$300000-500000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Type: Stone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

$40000-55000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

CNC Wire saw machine is an automatic profiling machine, designed for cutting complex shapes.such as solid columns, hollow columns, large stone lines and English letters, etc.

Type: Stone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

3YR

3YR

Italy

Italy

Prussiani Engineering S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesColumn, Arc Slab Cutting Machine

$30000-40000

Warranty: 12 Months

Usage: Marble, Limestone, Onyx, Sandstone, Travertine

Machinery Function Features:

China

China

FUJIAN XIANDA MACHINERY CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesStone Carving,Engraving Machine

$7000-9000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$20000-24900

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Tile Cutting MachinesMulti-Blade Cross-Cutter,Trimming

$8000-18000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Quartzite

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Surface Processing Machines Slab Polishing Line Machine

$50000-100000

Warranty: 12 Months

Usage: Granite, Marble, Onyx, Artificial Stone, Travertine

Machinery Function Features:

Type: Stone Factory MachinesStone Block Cutting MachinesVertical-Horizontal Block Cutting Machine

$29000-36000

Warranty: 12 Months

Usage: Granite, Marble, Artificial Stone

Machinery Function Features:

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCombined 5 Axis Saw & Waterjet Cutting

$78000-90000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Why sawjet is coming popular in stone cutting processing?

Do you need a trusted worker, an easy-to-maintain solution to sacle your gear on your terms, a beast loaded with value and power to take your business to the next level? HKNC-400J sawjet is the right stuff for you, which comes with cutting-edge technology and flexible customizable moudular design.

| Stone Machine | Strengths | Weaknesses |

| Cnc Bridge Saw | Sawing -- high speed, precise & cost lowest in straight and large arc cutting. | Cannot cut complex curves by sawing. Not so speed if by milling. |

| Water Jet Cutter | Clever, quick & cost low in complext curves or corner cutting. | Cost some higher and not so speed than cutting by sawing. |

HKNC-400J Saw & Jet with Itlian ESA CNC system and Pegasus software, intergrates a complete run and advantages of fully interpolated 5-axis bridge saw and 3-axis waterjet, optimizing to cut any material (marble, granite, quartzite, porcelian and more) with ease and increased speed, and stands out with its ability to do it at all with maximum efficiency.

Applications:

Features:

Optional Equipment:

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesStone Carving,Engraving Machine

$6600-7300

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Functional characteristics.

Y axis unilateral double row 30 linear guide(total 4 guide), the structure and the operation are more stable.

1.5M grinding high precision rack, Japan Xinbao reducer transmission, fast speed, high processing accuracy.

Machine body with thick square pipe and double horizontal support structure, no deformation, bearing

significant.

Three-axis high power, brand servo motor, Z-axis lock motor, long time work more stable.

The cable of whole machine is high quality, low temperature resistance, high folding resistance and long servicelife.

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Handling, Loading MachinesJib Arm/U Type Container Loader

$403-465

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone

Machinery Function Features:

2YR

2YR

China

China

XIAMEN SPEEDONE INDUSTRY CO., LTD

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

$28000-35000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Sandstone, Travertine

Machinery Function Features:

9YR

9YR

China

China

Xiamen Qicheng Superhard Material Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Surface Processing Machines Bush Hammering Machine

$36000-43000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone

Machinery Function Features:

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Sandstone

Machinery Function Features:

8YR

8YR

Italy

Italy

Sassomeccanica S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesStone Carving,Engraving Machine

$14500-14900

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Performance characteristics

Main Features

1) Adopt NcStudio CNC control system large color screen display, easy and simple to operate.

2) Break to rusume function. Continue carving from break point after power resuming from failure.

3) Compatible with Artcam JD Paint CAM software and other software programs.

4) High-performance new material motors and drivers can resist heat, shock and bad environment, ensure the working high speed and accuracy..

5) Professional vector control Inverter guarantee the variety working speed, smooth operation and make lower power consumption.

6) Aircraft-quality surface oxidized aluminum profile table which adding thicken PVC board, Enhancing the loading capacity of the platform.

7) Steel tube lathe bed, low center of gravity, strong bearing capacity, stable and long working life.

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

$31000-39000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Quartzite, Sandstone

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesColumn, Arc Slab Cutting Machine

$35000-45000

Warranty: 12 Months

Usage: Marble, Limestone, Onyx, Sandstone, Travertine

Machinery Function Features:

China

China

FUJIAN XIANDA MACHINERY CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$15000-24000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Quartzite, Travertine

Machinery Function Features:

Type: Stone Factory MachinesStone Surface Processing Machines Slab Polishing Line Machine

Warranty: 12 Months

Usage: Marble, Limestone, Onyx, Travertine

Spain

Spain

Plaquemarmol Santa Julia S.L.

Contact Supplier

Type: Stone Factory MachinesStone Factory Cleaning EquipmentsWater Treatment Equipment

Warranty: 12 Months

Usage: Granite, Marble

Machinery Function Features:

Italy

Italy

TESIMAG Srl

Contact Supplier

Type: Stone Factory MachinesStone Surface Processing Machines Single Head Polishing Machine

$700-800

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Quartzite, Sandstone

Machinery Function Features:

China

China

Foshan Haiyu Mechanical and Electrical Industry Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Surface Processing Machines Slab Polishing Line Machine

$1500-1800

Warranty: 12 Months

Usage: Granite, Marble, Onyx, Quartzite, Travertine

Machinery Function Features:

India

India

SJRC Machines India

Contact Supplier

Have a Question? Ask our expert

Tell Suppliers what you want to buy

Submitted successfully, thank you!