Stone Slab Cutting Machines in China

( 450 )Natural stone slab cutting machines vary depending on what materials are being processed. For example, on Stonecontact.com, you can find a rich list of different brands for cutting granite and marble with a wide variety of features. If you need a cutting/profiling machine for marble stairs or outdoor terrace pavers, you can examine waterjet cutting machines, multi-head automatic horizontal or vertical tile cutting machines, and profiling machines and choose the most suitable one for you. The same is true for granite and basalt. Granite and basalt are difficult materials to cut, but granite bridge saws and CNC cutting centers make your job easier. Whatever the challenge, there is sure to be a suitable stone cutter for your job in Stonecontact.com. When choosing a granite slab cutting machine, be sure to take advantage of detailed product technical information lists. Consider production rates, power ratings, and automation settings when choosing a bridge saw. All these features are listed and you can filter or search to find exactly what you need.

More Hide-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

FOB Price:$45000-50000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5 Axis CNC Bridge Saw

The machine is an integrated five-axis bridge cutting machine Ik-3050, it is much more big than IK 3520 and it's customized. Five-axis bridge cutting machine is for the different specifications of the plateand a variety of special-shaped copying processing(such as polygon, triangle, fan, countertop, oval,diamond, circle, rim of horse's belly, chamfer at anyangle, special-shaped copying and engraving). lt has the advantages of fast speed, high cutting precision, simple and intelligent operation, suitable for cutting slab, marble, granite, quartz stone, and other stone processing. lt is the first choice of project and stone processing enterprises. IKCNC

IKCNC

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesMulti Blade Automatic Slab Cutting Line

FOB Price:$42000-44000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone

Machinery Function Features:

The machine adopts advanced PLC intelligent control system to realize fully automatic control. High-efficiency stone cutting equipment with reasonable structure, reliable operation, high processing precision and high automation degree. Independent transverse beam with active frequency conversion adjustment can meet a variety of cutting requirements.

New Haineng

New Haineng

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

-

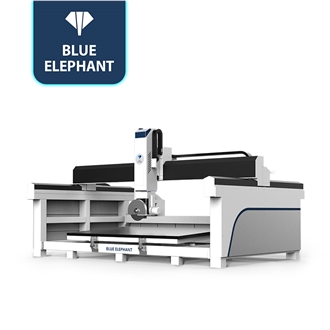

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

FOB Price:$30000-40000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Quartzite

Machinery Function Features:

This stone CNC machining center can cut quartz, marble, granite, and rock slabs with a powerful saw blade. It combines a saw blade and CNC router tools to achieve multiple advanced functions. For example, cutting and milling straight and inclined edges, chamfering, cutting arc edges, polygon, edge milling, edge tracking, and other powerful functions. The 5 axis bridge saw is widely used in the stone processing plants, kitchen countertop processing, background wall profiling, and other fields. It is the ideal machine for cutting stone slabs with different shapes and sizes.

1. It adopts 5 axis bridge cutting head, which is independently researched and developed and adopts the cast rotating bracket. This ensures good stability and flexibility during operation. 2. This bridge saw uses a high-precision RV reducer, ensuring better rotating precision of the cutting head.

3. It has built-in CAM software in the control system for the convenient of drawing designs and programming. Besides, it’s easy to learn the software to make designs.

4. The worktable can flip automatically up to 80 degrees, reducing human labor and facilitating the unloading process.

5. It is capable of cutting lengths of up to 2800mm, widths of 1200mm and thicknesses of 100mm. 6. The table automatically tilts up to 80 degrees. And the spindle is automatically rotated 90° or 360°by hydraulic pressure. Blue Elephant

Blue Elephant

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

FOB Price:$38000-41000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Hualong HKNC-450 5-Axis CNC Bridge Saw - Integrating Italian ESA control system with 35 years of Chinese manufacturing expertise, designed for global stone fabricators to achieve precision & profitability. From mass production to custom countertops, HKNC delivers ±0.02mm repeatability and modular scalability for quality-cost balance.

Core Advantages:

✅ ESA CNC System (Italy) - Dynamic vibration compensation for ±0.1mm contour accuracy - Power failure recovery & cloud-based parameter backup

✅ Human-Machine Collaboration - Canon EOS 1300D camera assists manual defect marking with 18MP clarity - Drag-and-drop nesting interface improves planning efficiency by 50%

✅ Localized Manufacturing Edge - CE-certified components + 48hr technical support

✅ 6 Customizable Upgrades Optional Modules:

- Retractable HSK Spindle - 24,000rpm for sink corners - Ideal for high-end vanity manufacturers

- Slab Thickness Sensor - Laser detection (5-200mm) with Z-axis compensation - Ideal for irregular slab processing

- Anti-Vibration Table - Air-cushion design for ≤2% breakage rate - Ideal for 3-6mm ultra-thin slabs

- CE Safety Scanner - Dual-channel infrared (EN ISO 13849) - Ideal for EU-compliant workshops

- Tool Presetter - Laser calibration cuts tooling time to 3mins - Ideal for high-mix job shops

- Hot-Dip Galvanized Frame - 5x corrosion resistance - Ideal for costal areas

Global Applications:

- Kitchen & Bath (80% Cases) - Quartz countertops: Sink cutting | Seamless slab splicing | L-shaped backsplash forming | Water groove milling - Porcelain slabs: Chip-free edging for 12mm slabs | Precision joint milling

- Architectural Cladding - High-speed panel cutting | Standardized stair tread processing | Complex geometic patterns

- Memorial Crafting - Relief lettering | | Complex geometic patterns

🔥 2025 Global Launch Offer

- First 10 orders receive Free CAD Toolkit (10 int'l countertop templates)

- Bonus ESA Remote Diagnostic Service ($2,500 value)

📞 Call +86-182-0602-1758 for multilingual technical proposals

Hualong

Hualong

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

FOB Price:$17500-19500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

This machine is controlled by microcomputer, its worktable can be 90 /360 rotating. Special structure for the guide pulley and side beam makes its cutting high accuracy, high stability, high efficiency. It's suitable for processing the marble&granite with high value. EASTERN PEGASUS

EASTERN PEGASUS

7YR

7YR

China

China

XIAMEN EASTERN PEGASUS CO., LTD.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$23000-24000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5 Axis CNC Bridge Saw

The machine is an integrated five-axis bridge cutting machine, for the different specifications of the plateand a variety of special-shaped copying processing(such as polygon, triangle, fan, countertop, oval,diamond, circle, rim of horse's belly, chamfer at anyangle, special-shaped copying and engraving). lt has the advantages of fast speed, high cutting precision, simple and intelligent operation, suitable for cutting slab, marble, granite, quartz stone, and other stone processing. lt is the first choice of project and stone processing enterprises. IKCNC

IKCNC

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCombined 5 Axis Saw & Waterjet Cutting

$36000-37000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

In five axis CNC system, coordination of X, while Y, Z and A, B of the two axis of rotation, the water jet cutting head can swing in any direction. When cutting, the computer according to the real-time calculation of the density and thickness of materials by cutting the workpiece, and control the cutting head along the cutting path and operation, to achieve three-dimensional complex shape of the workpiece cutting, such as surface slope cutting, chamfering and cutting high precision conical surface circular surface complex. The water jet and achieve higher performance and bring better benefits.

Cutting edge

1 strong versatility, almost all materials can be cut.

The 2 is cold water jet cutting, cutting does not produce thermal effects, no deformation, no residue, no ablation, does not change the physical and chemical properties of materials.

3 small slot, with the characteristics of cooling cutting, can improve the utilization rate of materials.

4 cutting medium only water and natural abrasives, cutting process does not produce other substances, is clean and environmentally friendly cutting process.

5 after cutting, the cutting surface is smooth and smooth, not in the cutting process of cutting objects have any damage, you can play a lot of cutting tools can not achieve the cutting operation.

The scope of application of water jet is very wide, from the metal material to non-metallic materials, materials from natural to artificial materials, from food to household goods, basically can be cut, "universal cutting machine" reputation.

Main application areas are:

1, ceramics, stone and other building materials processing

2, the processing of glass products, such as glass parts cutting, building decoration, craft glass

3, machinery industry, metal plate cutting

4, the advertising industry signs, art pattern cutting

New Haineng

New Haineng

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$30000-40000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt

Machinery Function Features:

It adopts PLC system and human-machine intelligent operation interface. The main engine uses double hydraulic lifting to combined with chrome guide sleeve, which is small clearance and wearable and beautiful. The design of multi-layer seal in the guide sleeve is waterproof, dustproof and leakproof. The left-right, forward-backward movement are all use encoder to control. With high precision megnetic railing ruler to detect, it can adjust the speed according to the stone material, thus the accuracy is higher. It uses the dedicated motor of stone machinery. The cutting head can rotate from 0 degree to 90 degree, enhancing the processing speed. The blade can tilt from 0 degree to 45 degree, enlarging the range of application. It is an integrated machine with compacted structure, easy operation and efficient cutting precision, which is the first choice for processing and chamfering for high value granite and marble.

Xianda

Xianda

1YR

1YR

China

China

XIAMEN XIANDA TRADING CO., LTD.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$23000-26000

Warranty: 12 Months

Usage: Granite, Marble

Machinery Function Features:

This machine adopts the PLC control system, with the best human-computer interaction interface, the operation interface is a combination of touch screen and mechanical button to control the interface, input operating parameters through interface (including cutting size specification, moving speed) Etc), the cutting process is automated and programmed.The touch screen adopts Chinese, English and Russian operation interface, Suitable for most countries and regions.This machine adopt infrared ray to confirm the way of the materials processing, combined with ultra-high precision rotary encoder and infrared laser device to locate, with high stability and easy to operating.The main machine is adopts slide lifting structure, the main head can be tilted to a maximum angle of 50 degrees, the operation is safe, and the lifting speed is stable.the whole machine is adopts separated structure, the base can match ,moving steel stand(separate type)、moving steel stand(one-piece) or customer homemade stand, easy for customer to choose.The left- right moving of the saw blade and the back- forth moving of the beam are driven by three-phase asynchronous motor, adjusts the speed by inverter control and encoder feedback. The beam and side beam adopt rack and pinion and v-shaped slide rail structure, with high precision, low failure rate and durable. JOBORN MACHINERY

JOBORN MACHINERY

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$14000-26000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

QCYI-450/600/700 (Sliding Plate Type) uses PLC system and human-machine Interface, combined with Ultra-high precision rotary encoder to locate and infrared device,uses inverter to control left-right feeding, adjusts the speed according to the stone material.It uses hydraulic lifting system,main spare parts adopt imported good-quality materials.Thus the whole machine is featured as high cutting effciency,high cutting precision, high stability,easy-operating to suit granite and marble with high value and big size. QCNG

QCNG

9YR

9YR

China

China

Xiamen Qicheng Superhard Material Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$19300-21700

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

SQC-450/600/700 (Sliding Plate Type) uses PLC system and human-machine Interface, combined with Ultra-high precision rotary encoder to locate and infrared device,uses inverter to control left-right feeding, adjusts the speed according to the stone material.It uses hydraulic lifting system,main spare parts adopt imported good-quality materials.Thus the whole machine is featured as high cutting effciency,high cutting precision, high stability,easy-operating to suit granite and marble with high value and big size. JULUN

JULUN

China

China

FUJIAN NANAN JULUN MACHINERY CO., LTD.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$20000-30000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite

Machinery Function Features:

5 axis CNC stone cutting bridge saw adopts an automatic computer control system, which can realize manual programming or CNC programming and other programming methods to automatically complete cutting operations. It can conveniently perform horizontal cutting, longitudinal cutting, arc cutting, elliptical cutting, round cutting, arbitrary angle cutting, concave-convex edging, shaped cutting, special-shaped processing and more occasions with powerful functions.

5 Axis Bridge Saw

5 axis CNC bridge saw is an automatic stone machining equipment that can complete the processing of pentahedron special-shaped curved surfaces at one time through five-axis linkage control, that is, three linear moving axes and two rotating axes.

It is a type of Automatic CNC Machine tailor-made for the majority of stone fabricators by IGOLDENCNC in order to meet the cutting plans of stone machining manufacturers. It has various processing modes of cutting, milling, engraving, and drilling. The bridge saw features with multiple functions, small footprint, simple operation, precise cutting, quick and convenient conversion of different functions.

Durable

Good quality steel is used as the mechanical parts and reliable electric parts are used to guarantee high reliability & durability.

Multifunctional

It can do chamfer cut, straight cut, arc cut, arc cutting, shape cut, milling, drilling, line cut, and edging. With optional sensor, profiling function can be added.

User-Friendly

Automatic touch screen cutcam system,Professional CNC system, easy to set and machining, touch control, simple operation.

Precise

Magnetic ruler is adopted for slicing measure.

Laser device for accurate alignment.

5 Axis CNC Bridge Saw Machine Quartz Slab Production Line for Stone Cutting and Polishing

What Can 5 Axis CNC Cutting Bridge Saw Do?

The 5 axis CNC bridge saw can cut any shape of stone lines, arc edges, duckbill edges, straight edges, beveled edges, non-slip grooves, dry hanging grooves, sink processing, and special-shaped edge forming.

- 1. Countertop cut: blank slab cutting, rear gear cutting, reverse buckle cutting, hanging material, L-shaped table to length, corner cutting reserved, 45-degree chamfered front mouth, pot hole, stove hole, Diagonal line cutting, cutting at any angle of the wall crenel.

- 2. Automatic cut: Realize the import of CAD drawings, cutting completely according to the drawing style, no need to enter complex data.

- 3. Bridge cut: It has all the functions of bridge cutting equipment on the market.

- 4. Roman column cut: Cut the square Roman column main board and both sides at one time, and simultaneously chamfer 45 degrees on both sides to complete the Roman column hole cutting.

- 5. Arc-shaped line cut: Install the line grinding head to complete the arc-shaped line shape, and cut into a rough arc-shaped line as a whole, which requires manual polishing.

- 6. Concave-convex cut: According to the arc, grind out the desired convex or concave plate. It is mainly used for grinding and making curved plates of special-shaped background walls or special-shaped decorative panels.

- 7. Abnormity cut: To solve the problem of uneven walls, cut out asymmetric quadrilaterals or isosceles trapezoids.

IGOLDEN

IGOLDEN

China

China

Shandong iGolden CNC

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$20000-28000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Quartzite, Sandstone

Machinery Function Features:

1.45 degree mitre cutting (Hydraulic)

2.Equipped with wireless controller,The size of controller is like a IPHONE, easy to carring.

3.High precise magnescale

4.Linear guide rail

5.Table 360 degree rotate and lock at every 45 degree and can lock at any angle (can control by wireless controller)

6.cutting head can be control by cross command switch,touch screen interface

7.Inches operation system

8.The electricl elements all used imported brand,Siemens from German, Mitsubishi from Japan

9.Bearning is NSK form Japan

10.Hydraulic system is Ashun from Taiwan

11.With heavy duty steel legs

12.Blade motor 25HP XinAn Machinery

XinAn Machinery

China

China

Fujian XinAn Machine Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$19300-20300

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Sandstone, Travertine

Machinery Function Features:

This machine adopts PLC programmable control system, man-machine integration of touch screen operation interface, with high precision rotary encoder and the infrared liner, cutting left and right adopts the frequency converter to control the speed, speed can be adjusted according to the stone material, lift up and down adopts hydraulic, the high speed moving parts adopt imported high quality spare parts, so it cutting with high efficiency, high cutting precision, high stability, easy and flexible operation etc, especially suitable for the high value of large specifications of granite, marble slabs cutting. FURUITE

FURUITE

China

China

Fujian Province Furuite Machinery Co.,Ltd

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCombined 5 Axis Saw & Waterjet Cutting

$90000-120000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Quartzite, Sandstone, Travertine

Machinery Function Features:

Why Hualong sawjet - the most efficetly & perfect cutting technology!

Hualong HKNC-650J Sawjet, featuring everything a technologically advanced bridge saw and water jet needs today, is a new 5-axes cnc machine built for speed, precision and excellence. It allows almost limitless cut out possibilitis:

- * With water jet cut flexiblely any curve, corner or complex shapes with ease.

- * With saw blade cut smoothly, quickly and most cost efficienctly for straight, big arcs, chamfering and notch on slab surface.

The two cutting ways are combined alternately and automatically according to preset programs and/or at will, which allows to optimize cuts thus ensuring waste minization (there is no need to move the slab or the workpieces) It's perfect in cutting granite, marble, other natural stone, composite, and ceramic slabs.

With HKNC-650J, a beast that's loaded with value and power, you're set for cutting success, now and for years to come!

Features:

- 1) 5-axis waterjet + 5-axis bridge saw

- 2) Italian ESA cnc

- 3) Italian Pegasus software

- 4) Advanced PC controller with 21.5" touch screen

- 5) Slab image capture system

- 6) Automatic lubrication system

- 7) Wireless remote pendant

- 8) Red laser guidance

- 9) Tilting Loading Table (up to 85°)

- 10) Optional - blade presetting unit

- 11) Optional - slab thickness detector

- 12) Optional - auto-height & anti-collision system

- 13) Optional - slab fixing system

- 14) Optional - vacuum Manipulation

- 15) Optional - safety barrier door system or infrared safety barrier beam

- 16) Optional - fully galvanized frame

- 17) Optional - air conditioner for electrial cabinet

Benefits

- • Easy to use

- • Automatic, powerfull cutting

- • Rapid, efficient cutting

- • Less waste - Accurate programming of cuts can result in less waste

- • +33% productivity without manual movements

- • Increase material yield by 10-20%

- • High reliability & minimal maintenance

Hualong

Hualong

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$20000-30000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

QCYI-700X uses PLC system and Human-machine Interface , combined with Ultra-high precision rotary encoder to locate and infrared device , uses inverter to control left –right feeding , adjusts the speed according to the stone material . It uses hydraulic lifting system , main spare parts adopt imported good –quality materials , the head can rotate 0-50°, applied in a wider range . Thus the whole machine is featured as high cutting efficiency , high cutting precision , high stability , easy-operating to suit granite and marble with high value and big size , and shaped stone products. QCNG

QCNG

9YR

9YR

China

China

Xiamen Qicheng Superhard Material Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCombined 5 Axis Saw & Waterjet Cutting

$38000-46000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

1.High Efficiency & Energy saving Intensifier Unit:

Exclusive patented Energy-saving &High efficiency Intensifier assembly(Patent No. : ZL 2017 2 1116875. 3) ;

Power: 22KW,220V/380V/415V/480V,50Hz/60Hz; Max Pressure : 450MPa, Working Pressure :≤340MPa; Max Water flow:3.7L/MIN

Dual Cooling mode: Air Cooling & Water Cooling; Oil Pressurized ratio: 1:27;

German Schneider electrical components

2.CNC Controller System:

Industrial PC ,with 19-inch industrial display,Industrial controller, Windows 10 operation system ;

Shanghai Weihong professional waterjet CNC Control system

Shanghai Weihong special waterjet cutting software,the listed company product, advanced and reliable, easy to lear

3.CNC Cuting Table:

Gantry Structure, the water tank adopts 16mm plate and double- layer keel structure

X Axis Cutting stroke:3000mm/ 4000mm ;Y Axis Cutting stroke: 2000mm; Z Axis Cutting stroke: 100mm

Repeat positioning accuracy: ±0. 01mm; Cutting accuracy: ± 0.1mm;Rapid Position Speed: 10m/min

X, Y and Z Axis control mode:Shanghai CNC (Weihong) bus servo control system

Vertical and Horizontal beams are welded with H-shaped structure steel and reinforcement bars structure;

oil - immersed guide wire rod with dust protection structure; Imported TBI brand ball screw and guide rail

4.AC 5Axis Cutting Head:

rol Axis : 5Axis

A Axis Rotation : ±75 °

C Axis Rotation: Infinite Rotation

Angle control accuracy: ±0.01

Equipped with Weihong laser measured height device

Probe system and Carema system are optional,which can generate the basin cutting path automatically .

5. Auto Sand Supply System

550IBS capacity ,can supply sand for 10hours continuous working

Air compressor of 0. 2MPa is required,power is not less than 3kw.

Neng Bo Waterjet

Neng Bo Waterjet

China

China

Foshan Nengbo Machinery Co.,Ltd

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$32800-38800

Warranty: 12 Months

Usage: Granite, Marble, Artificial Stone, Quartzite

Machinery Function Features:

1. Compact size without needing the ground base.

2. With advanced CNC control system and all pattern operation, the machine can be operated without professional operators.

3. With powerful functions, the machine can work almost all the jobs of a small factory.

4. With less electricity and more efficiency, the cost is decreased much.

5. High quality accessories and electric parts are used to secure long service life and low cost. OMC

OMC

China

China

Laizhou Oriental Machinery Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$17500-19500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

This machine is composed of the Crossbeam, longitudinal rail boxes, conductors, lifting cylinders, side beams and cement foundation.

Using laser instrument, Italy imported magnetic scale, microcomputer PLC. The machine is full automation and easy to operate, the work efficiency also improved. There are 4 models of this machine SZQJ-400/600/700/800.

The worktable can be rotated for 45, 90 and 360 degrees, a variety of rotation methods.

The main motor power can be selected from 15KW, 18.5KW and 22KW. It is available as an option. It meets the cutting requirements of large-size plates on the market.

KAIDA

KAIDA

China

China

Fujian Province Kaida Stone Machinery Co.,Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$9999-49999

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Machine Features

1. XYZAC 5 axis, A axis 0 to 90-degree automatic rotation, C axis 0 to 360-degree

automatic rotation.

2. Vertical and horizontal cutting, multi-angle diagonal cutting.

3. Four sides miter (any angle between 0°-90°).

4. Cutting circle, Ellipse cutting, Sector cutting, L-tops cutting, Sink cut-out, Arc cutting.

5. Cutter bits, Contouring, Suction moving.

6. Table tilts 85 degree to load slabs easily.

7. Intelligent control system.

8. With camera.

Applicable Industry & Material

Applicable industry: sintered stone application industry, fabricated building materials industry, home decoration materials industry, cutting marble, artificial stone, quartz stone and other materials.

Applicable material: sintered stone, ceramic plate, quartz stone, marble, etc.

Cutting function display:

Specification Sheet, Arbitrary Line, Countertop +/-45°, Miter, Profiling, Regular, Polygon, Nesting, Suction, Moving Grid, Circle, Sector, Horse Belly, Square Plate/Sink Cutout, Drilling/Polishing, DXF/NC CAD, G-CODE, Camera Ganger CNC

Ganger CNC

China

China

Ganger CNC Co., Ltd

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesMulti Blade Automatic Slab Cutting Line

$15000-18000

Warranty: 12 Months

Usage: Marble, Limestone, Onyx, Sandstone, Travertine

Machinery Function Features:

1200mm marble Splitting cutting machine stone cutting machinery GT

GT

China

China

XIAMEN GLOBE TRUTH (GT) INDUSTRIES CO.LTD.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$11000-20000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

HLQC-600/800 infrared automatic stone bridge cutting machine has two type, adopting PLC system and Human-machine interface, togethering with ultra-high precision rotary encoder positioning and infrared device, with Chinese & English double operation language, using inverter to control left-right feeding,adjusting the speed according to stone material, using hydraulic lifting system which equiped through 4 guide post, also this machine provide the unique side beam protection device, main spare parts adopt imported well-quality materials.

The whole machine is featured with high cutting efficiency, high cutting precision, high stability, easy to operate, specially high value granite and big size marble -

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$25000-40000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

QCYI-1200 uses PLC system and Human-machine interface, combined with Ultra-high precision rotary encoder to locate, and infrared device, it uses inverter to control left-right feeding, adjust the speed according to the stone material. It uses hydraulic lifting system, and main spare parts adopt imported good-quality materials. Thus the whole machine is featured as high cutting efficiency, high stability, easy-operating to suit specially shaped stone products, tombstone and curb stone.. QCNG

QCNG

9YR

9YR

China

China

Xiamen Qicheng Superhard Material Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$20000-24900

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

SQC-600-4D(Guide Post Type) uses PLC system and human-machine interface, combined with Ultra-high precision rotary encoder to locate and infrared device, uses inverter to control left-right feeding,adjusts the speed according to the stone material.It uses hydraulic lifting system, combination of Chrome-plated guide pin and wear guide bush,with small gap, wearable, beautiful structure, and Guide Sleeve with multi-layer seals, with waterproof, dustproof, anti-spill, improving the service life. Main spare parts adopt imported good-quality materials. Thus the whole machine is featured with high cutting efficiency, high cutting precision, high stability, easy–operating to suit granite and marble with high value and big size. SHUINAN MACHINE

SHUINAN MACHINE

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCombined 5 Axis Saw & Waterjet Cutting

$78000-90000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Why sawjet is coming popular in stone cutting processing?

Do you need a trusted worker, an easy-to-maintain solution to sacle your gear on your terms, a beast loaded with value and power to take your business to the next level? HKNC-400J sawjet is the right stuff for you, which comes with cutting-edge technology and flexible customizable moudular design.

Stone Machine Strengths Weaknesses Cnc Bridge Saw Sawing -- high speed, precise & cost lowest in straight and large arc cutting. Cannot cut complex curves by sawing. Not so speed if by milling.

Water Jet Cutter Clever, quick & cost low in complext curves or corner cutting. Cost some higher and not so speed than cutting by sawing. HKNC-400J Saw & Jet with Itlian ESA CNC system and Pegasus software, intergrates a complete run and advantages of fully interpolated 5-axis bridge saw and 3-axis waterjet, optimizing to cut any material (marble, granite, quartzite, porcelian and more) with ease and increased speed, and stands out with its ability to do it at all with maximum efficiency.

Applications:

- • Countertops

- • Sinks

- • Tap holes

- • Powerpoint recesses

- • Edge profiles

- • Engravings

- • Blade profiling

Features:

- Powered up with Itlian ESA cnc and Pegasus software

- 21.5” large touch screen

- Industrial hydraulic tilt table

- Flexible, operator-friendly cuts in stone, granite...

- Compact desig and small footprint

- Discs & Waterjet Cutting

- Slab locate camera system

- Automatic lubrication system

- Red laser guidance

- +33% PRODUCTIVITY WITHOUT MANUAL MOVEMENTS

- Less waste - Accurate programming of cuts can result in less waste

- Direct connection for remote assistance

- Online monitoring system

Optional Equipment:

- * Suction cup gripping system

- * Slab thickness detector

- * Blade measuring unit

- * Automatic washing system

- * Auto height system

- * Anti-collison system

- * Air conditioner for electrical cabinet

- * Corrosion-resistant galvanized frame

- * Safe front doors or infrared light curtain

Hualong

Hualong

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$15000-24000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Quartzite, Travertine

Machinery Function Features:

1.The machine adopts a bridge-type integrated structure, the machine bed is strong and stable, and has good stability.

2.The 4-axis adopts high-precision linear square rail, which has high precision, wear resistance and long service life

3.The machine head can be rotated in parallel of 0-90 degrees any angle's chemfer cutting, and can be cut horizontally, vertically, circular,and diamond-shaped.

4.The machine head can automatically perform 45-degree chamfer cutting, with high precision and high efficiency.

5.The system adopts independent research and development PLC programming system, touch screen operation interface, convenient operation and strong humanity.

6.The 4 axis adopts high-power servo motor, which has fast walking speed and high precision.

7.One-piece structure, no need to disassemble, easy to install and easy to move.

8.The platform can be tilted from 0 to 85 degrees, which is convenient for placing large stones. -

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$26000-29000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Based on the original worktable slicing machine and edge cutting machine, an extra trolley is added to the cutting time for loading or unloading of stone, saving loading and unloading time and greatly improving work efficiency Dafon

Dafon

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$11000-18000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Qicheng HQC400/600/700-4D Laser Bridge Cutting Machine(Guide Post)

Features:

1.Special structure for the guide pulley and side beam makes its cutting high accuracy, high stability, high efficiency

2. The machine is controlled by a microcomputer, its worktable can be 90 /360 rotating.

3. PLC terminal controlling system for convenience of setting parameters through LCD touch screen.Each slab is cut automatically individually throughout the process, with blade input speed flexibly adjusted by variable frequency adjustable speed system according to slab characteristics;

4. An infrared ray cutter aligner is installed;

5. Double hydro-cylinder: blade elevation is more stable.

It's suitable for processing the marble&granite with high value. QCNG

QCNG

9YR

9YR

China

China

Xiamen Qicheng Superhard Material Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$31000-34000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4-Axis CNC Stone Bridge Cutting Machine | Italian ESA System & 35+ Years Expertise

Hualong Machinery | Precision Engineered for Global Stone Fabricators Since 1990

Hualong HLNC-400 Plus 4-Axis CNC Stone Bridge Saw is an intelligent cutting solution engineered for marble, granite, quartz, and other hard materials. Equipped with advanced CNC technology and 4-axis synchronization (X/Y/Z/C), it delivers complex 3D shaping, beveling, grooving, and flat processing, ideal for high-precision countertop fabrication (kitchen islands, vanity tops, bar counters) while supporting applications like wall cladding, flooring, architectural decoration and memorial carving.

Advantages

Advanced Italian Technology

- ESA CNC System & Zeus Software : Achieve ±0.1mm precision with Europe’s leading control system.

- 24,000 RPM Telescopic Electric Spindle : High-speed corner cutting for granite, marble, and engineered stone, reducing processing time by 30%.

Durable & Intelligent Design

- Galvanized Main Frame : Corrosion-resistant structure for 10+ years lifespan in harsh environments (optional).

- Automatic Tool Presetting Unit : Minimize downtime with laser-assisted tool calibration (optional).

Operator-Centric Features

- Vacuum Lifter System : Safely handle slabs up to 50mm thickness (optional).

- Anti-Vibration Rubber Table : Ensure stability during high-frequency cutting (optional).

Why Global Clients Choose Hualong?

✅ 35+ Years OEM/ODM Experience : Customized solutions for USA, EU, and Middle East markets.

✅ Energy-Saving Design : 15% lower power consumption vs. industry average (ISO 50001 certified).

✅ 24/7 Global Technical Support : On-site installation & remote troubleshooting available. Hualong

Hualong

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesMulti Blade Automatic Slab Cutting Line

$26900-29900

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Quartzite

Machinery Function Features:

The Slicing Machine has a double worktable, the main body adopts the integrated casting structure, and the material is thick and steady. The main shaft and other key parts are treated with high-frequency modulation, which is not easy to wear. It has the features of a high degree of automation, simple operation, high cutting standards, etc. It is suitable for cutting granite with high hardness such as kerbstone or thick slab Dafon

Dafon

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$52000-54000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate

Machinery Function Features:

The whole process of kerbstone production

After cutting the stone height by block cutter, a worker hoisted the material to the curbstone slicing machine, another worker hoisted the curbstone cut along the curbstone cutting machine line to the curbstone chamfering machine for grinding and chamfering, and a third worker unloaded and packaged the material by a small crane behind the chamfering edger. The process requires only three workers to operate, greatly saving labor costs. The whole production continuity is continuous and the stability is good. DAFON

DAFON

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$10500-11000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Quartzite, Sandstone

Machinery Function Features:

1. The machine adopts microcomputer control and, a touch operation interface, with wireless remote control, the operation is more flexible and free.

2. The main control components are all internationally famous brand components, the horizontal cutting adopts step-less frequency conversion speed regulation, and the beam and vertical slicing mechanism adopts a linear guide rail and high-precision magnetic ruler for counting, which ensures the smooth and stable operation of the machine.

3. The fuselage is integrated with the base of the worktable, which has a small footprint (less than 15 square meters), easy installation, convenient transportation, etc., which ensures the stability of the machine.

4. This machine is especially suitable for home improvement factories to cut slate, artificial stone, marble, granite, and other home improvement building materials. Dafon

Dafon

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$21500-24500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

HLSQ-400 Delta PLC 4-Axis Stone Bridge Saw - Precision Template Cutting at Affordable Value

The HLSQ-400 4-axis bridge cutting machine integrates Delta PLC control with pre-loaded geometric templates, delivering cost-effective precision for standard stone fabrication. Designed for marble, granite, and engineered stone, it effortlessly executes circle, oval, diamond, polygon, trapezoid, fan-shaped, and ogee edge profiles through synchronized 4-axis motion. Ideal for entry-level workshops and mid-volume production.

Note: This model focuses on solid template-based cutting, NOT for hollow-out patterns, 3D engraving, or free-form complex shapes.

Core Advantages

✅ Ready-to-Use Template Library

18 built-in geometric templates + USB import for custom DXF files (2D only)

✅ Delta PLC Precision

±0.15mm repeatability with automatic tool compensation

✅ Rapid Setup

Template-based programming reduces job preparation by 70% vs manual CNC coding

✅ Budget-Friendly Performance

40% lower ownership cost than full CNC systems with equal cutting accuracyTechnical Specifications

| Control System : Delta PLC + 7" HMI Touchscreen

| Cutting Dimensions : 3300×2000×70mm

| Spindle Power : 15kW (220V/380V optional)

| Template Capacity : 18 preset + 50 user-defined

| Compatible Materials: Natural/Engineered Stone (Mohs ≤6)Target Users

◼ Small stone workshops expanding from manual to semi-auto production

◼ Construction contractors requiring batch processing of standard profiles

◼ Kitchen countertop fabricators for basic edge shaping

◼ Tile suppliers producing geometric decorative piecesWhy Choose HLSQ-400?

⌛ No CNC Expertise Needed – Operate like a pro with 1-day training

💸 Zero Over-engineering – Pay only for the functions you actually use

🔧 Proven Reliability – Over 300 units deployed in Southeast Asian marketsService & Offer

📥 Free Trial – Send your stone sample, get a cutting demo video in 72hrs

📦 Doorstep Support – Local technician assistance in 15+ countriesCall to Action

【Limited-Offer Package】

First 10 orders receive:

① Free diamond blade (¥2,500 value)

② On-site training vouchers

③ 24/7 priority technical hotline📞 +86-182-0602 1758 | 📧 [email protected]

Hualong

Hualong

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$25000-35000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Quartzite, Sandstone, Travertine

Machinery Function Features:

This equipment is improved and upgraded based on a bridge cutter machine, it-adopts PLC to control multiple saw blades cutting at the same time, it can use up to pieces of saw blades with a diameter of 800mm, the trolley can be rotated by 90, which saves the cutting process and greatly improves the production efficiency, and the casting cross beam and the more powerful motors make efficient, it is suitable for the paving stones, kerbstone, and cobblestone, etc. DAFON

DAFON

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$10500-16000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Product Description

An infrared bridge stone cutting machine is a type of cutting machine that is commonly used in the stone industry to cut and shape natural stone slabs. It uses infrared technology to guide the cutting process, allowing for precise and efficient cuts.

The infrared technology used in the machine involves the use of infrared sensors to detect the edges and contours of the stone slab. These sensors send signals to the cutting blade, which adjusts its position and angle to match the shape of the stone. This results in precise cuts that are consistent in size and shape.

Machine Features

1.The machine adopt cast iron on the main part of machine body ensure stability while cutting

2.The cutting speed is controlled by the inverter to achieve stepless adjustment, the head movements, table title up, rotation, and position use hydraulic transmission to move. it can be cut by manually and fully automatic easily.

3.It adopts PLC programmable control system and touch screen operator and combined with high precision encode positioning(Omron brand encoder)

4.The worktable is controlled by hydraulic rotation

5.It is applicable to cutting the valuable and large-sized stone board for many specifications

Main Parts of the Machine:

1.Motor: branded motor in China providing stability while cutting

2.Hydraulic station: seven ocean hydraulic system from Taiwan

3.Cement foundation or metallic foundation optional

4.Worktable size: 3000*2000*700mm

5.Rotation: 0-90°and 0-360°(every 45°one rotation) two options & 0-85°tilt

6.Material: adopt #14 Universal Beam instead of #12 box iron, stronger frame to carry stone

7.Inside details: 8 rotation wheels inside the worktable not 6

8.Infrared line to show the cutting path which ensure precise cutting and high cutting quality

After Sales Service

Pre-Sales Service

* Inquiry and consulting support.

* Configure the best machine line according to customer condition

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Lifetime technology maintenance in free and spare parts supply.

Related Products Dafon

Dafon

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$27500-29500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

HLSQ-400 Plus 4-Axis Bridge Saw - All-in-One Solution for Countertop Fabrication

Saw-Milling Hybrid System | Sink Cutout in 15 Mins

Product Overview

The HLSQ-400 Plus enhances the standard model with a retractable electric spindle (0-24,000rpm), enabling combined sawing and milling operations. Equipped with quick-change tool holders, it efficiently processes sink cutouts, faucet slots, and edge profiling while performing straight cuts - replacing traditional two-machine setups. Optimized for quartz/engineered stone countertops.

Note: Specializes in 2.5D milling, not for 3D relief carving (See HKNC-500 5-Axis for advanced needs)

Key Upgrades

✅ Dual-Mode Hybrid Processing

Switch between blade/milling tools in 0.8s with auto-tool compensation

✅ Countertop Template Kit

Pre-loaded 15 sink cutout templates + G-code import for custom shapes

✅ Premium Surface Finish

HIWIN guides + ≤0.01mm spindle runout ensure Ra≤3.2μm milled surfaces

✅ ROI Accelerator

Process 40 countertops/day with ROI payback within 6 monthsTechnical Highlights

Item Specification Spindle Speed 0-24,000rpm (VFD-controlled) Max Milling Depth 70mm (Engineered Stone) Sawing Speed 12m/min (Diamond Blade) Work Area 3500×2100mm (Customizable) Power Consumption 28.2kW (35% Energy Saving) Ideal For

◼ Kitchen countertop sink cutout & edge polishing in one pass

◼ Bathroom vanity faucet slot milling

◼ Commercial bar tops recessed fixture machining

◼ High-volume quartz window sill chamfering & trimmingLaunch Promotion

📅 Order before 2025/7/31 to get:

① 15% off first consumables order

② Dedicated tech support 7×12hr

③ 3-year spindle warranty extensionCall to Action

📞 +86-182-0602-1758 Hualong

Hualong

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$13500-15000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Introduction of Infrared 45 Degree Bridge Saw Cutter

The Infrared 45 Degree Marble Granite Bridge Saw Cutter is an upgraded version of our latest machine. Compared with the Infrared stone cutting machine, which can only cut at 90 degrees, it has been upgraded and can cut at a 45-degree bevel. Using infrared technology, it can cut various stones quickly and accurately. Infrared 45-degree Bridge Saw Cutter adopts an intelligent PLC control system, which is easy to operate and can easily complete stone cutting work without professional skills.

Feature of Infrared 45 Degree Bridge Saw Machine

Cast beam structure: The double beam adopts a cast beam structure, which is more sturdy and durable, can withstand outdoor use, and can be used in external environments.

45 DEGREE PRECISE CUTS: The 45 45-degree bridge Saw Machine is a specialized tool that handles angled cuts with ease, perfect for creating unique and intricate designs.

Versatile Cutting Options: The Bridge Saw Machine offers a range of cutting options, including straight cuts, bevel cuts, and miter cuts, providing flexibility and versatility to complete your projects. Dafon

Dafon

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$29200-30700

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5 Axis CNC Bridge Saw

The machine is an integrated five-axis bridge cutting machine, for the different specifications of the plateand a variety of special-shaped copying processing(such as polygon, triangle, fan, countertop, oval,diamond, circle, rim of horse's belly, chamfer at anyangle, special-shaped copying and engraving). lt has the advantages of fast speed, high cutting precision, simple and intelligent operation, suitable for cutting slab, marble, granite, quartz stone, and other stone processing. lt is the first choice of project and stone processing enterprises. IKCNC

IKCNC

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$20000-30000

Warranty: 12 Months

Usage: Granite, Marble, Slate, Quartzite, Sandstone

Machinery Function Features:

Description

This 4+1 CNC bridge saw machine features a 5.5KW liquid-cooling spindle that can alternate with a saw blade, significantly improving production efficiency. Additionally, compared to the standard bridge saw, it includes an industrial camera and material-shifting function. This allows users to select desired patterns from the system’s preset designs, greatly reducing drawing time.

Features

1.The 4 +1 CNC bridge saw can realize cross cutting, vertical cutting, bevel cutting, rhombus cutting, circle cutting, oval cutting, 45°chamfering, under-counter basin and in-counter basin cutting, etc.

2.The saw blade diameter of this 4+1 bridge saw is 350mm, and the spindle speed is 24000rpm/min. It can achieve a maximum cutting thickness of 80mm, and the spindle and saw blade can work alternately without affecting each other.

3.It uses an industrial camera, you can select the pattern you want from the system preset patterns, set parameters such as side length and angle, and plan the path. The camera takes pictures, which greatly saves drawing time.

4.This machine is equipped with a suction cup to realize the material moving function and avoid accidental cutting of surrounding materials. Blue Elephant

Blue Elephant

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$15500-19500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

1.Super-heavy type working plaform.The platform uses heavy large size profiles welding together,larger than the table in market,with more durable.

2.Taiwan famous hydraulic system.The hydraulic components from Taiwan first-line brand,react more quickly,works more stable.

3.Humanized human-computer interaction interface.User-friendly interface,with more simple operation,easy to use.

4.Imported and domestic premium brand electric components.Germany Siemens inverter,feeding more stable;electrical components are used imported or domestic first-line brands.

5.Domestic premium brand main motor with high efficiency and more energy saving,make the cutting more powerful,and saving electricity more.

6.Single-Beam lifting machine(Optional).

7.Steel rigid stand(Optional). JOBORN MACHINERY

JOBORN MACHINERY

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$15000-17800

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

This machine is controlled by microcomputer, its worktable can be 90°/360°rotating. Special structure for the guide pulley and side beam makes its cutting high accuracy, high stability, high efficiency. it is especially suitable for processing large granite and marble plates.

Xianda

Xianda

1YR

1YR

China

China

XIAMEN XIANDA TRADING CO., LTD.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCombined 5 Axis Saw & Waterjet Cutting

$38000-46000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

1.High Efficiency & Energy saving Intensifier Unit:

Exclusive patented Energy-saving &High efficiency Intensifier assembly(Patent No. : ZL 2017 2 1116875. 3) ;

Power: 22KW,220V/380V/415V/480V,50Hz/60Hz; Max Pressure : 450MPa, Working Pressure :≤340MPa; Max Water flow:3.7L/MIN

Dual Cooling mode: Air Cooling & Water Cooling; Oil Pressurized ratio: 1:27;

German Schneider electrical components

2.CNC Controller System:

Industrial PC ,with 19-inch industrial display,Industrial controller, Windows 10 operation system ;

Shanghai Weihong professional waterjet CNC Control system

Shanghai Weihong special waterjet cutting software,the listed company product, advanced and reliable, easy to lear

3.CNC Cuting Table:

Gantry Structure, the water tank adopts 16mm plate and double- layer keel structure

X Axis Cutting stroke:3000mm/ 4000mm ;Y Axis Cutting stroke: 2000mm; Z Axis Cutting stroke: 100mm

Repeat positioning accuracy: ±0. 01mm; Cutting accuracy: ± 0.1mm;Rapid Position Speed: 10m/min

X, Y and Z Axis control mode:Shanghai CNC (Weihong) bus servo control system

Vertical and Horizontal beams are welded with H-shaped structure steel and reinforcement bars structure;

oil - immersed guide wire rod with dust protection structure; Imported TBI brand ball screw and guide rail

4.AC 5Axis Cutting Head:

rol Axis : 5Axis

A Axis Rotation : ±75 °

C Axis Rotation: Infinite Rotation

Angle control accuracy: ±0.01

Equipped with Weihong laser measured height device

Probe system and Carema system are optional,which can generate the basin cutting path automatically .

5. Auto Sand Supply System

550IBS capacity ,can supply sand for 10hours continuous working

Air compressor of 0. 2MPa is required,power is not less than 3kw.

Neng Bo Waterjet

Neng Bo Waterjet

China

China

Foshan Nengbo Machinery Co.,Ltd

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$38000-45000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

CNC450/600/700-5 AI five-axis CNC bridge cutting machine. This series adopts industrial computer and is equipped with Windows system, which can realize manual programming or PC programming and other programming methods to automatically complete processing operations. Cutting, grooving, countertop processing, special-shaped processing, etc.,

Standard camera function for visualization and easy operation. The tool setting function can measure the diameter of the saw blade in real-time and compensate for wear and tear,it could ensure makes the processing non stop.

The structure adopts an integral steel frame, which has been treated with stress relief in multiple processes, and has a stable structure, easy installation and high precision. The main motor adopts the spindle motor, which can be equipped with a milling cutter.

In terms of transmission, the XY axis adopts high-precision rack and pinion transmission and high-precision linear guide rail guidance. The Z axis is driven by a ball screw and guided by a high-precision linear guide. A-axis and C-axis all use precision robot reducer.

The whole machine has high positioning accuracy, repeated positioning accuracy, good cutting accuracy and high stability, and is especially suitable for the processing of high-value and large-sized granite, marble and slate.

Main Feature:

1.5 Axis linkage control with CNC control system;

2.Easy to use interface with 17" color touch-screen;

3.The machine is equipped with an industrial computer, embedded touch screen, supports CAD file import;

4.The machine adopts integrated structure, the frame and beam are welded by high-quality carbon steel plate and profiles, solid and reliable, high stability;

5.The X-axis lateral movement adopts servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision helical rack and pinion drive;

6.Y-axis longitudinal movement adopts double servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision helical rack and pinion drive;

7.The Z-axis main machine lifting adopts servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision ball screw drive;

8.A-axis head tilt rotation 0-90° and C-axis head plane rotation 0-360° are driven by servo motor + precision robot RV reducer, supporting five-axis linkage, high dimensional precision and shape precision;

9.Working platform can tilt 85 degrees, easy for slabs loading;

10.Photo taking & tool setting function;

11.Individual engraving head(optional);

12.Suction cup function(optional);

13.Thickness measurement function(optional);

14.Safety protection door(optional);

JOBORN MACHINERY

JOBORN MACHINERY

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

-

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$20000-25000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Color can change according client requirment

We will give the fundation drawing, need do the cement wall for both side to supoort the side beam

The cross beam is casted. The main frame consists of four pipes seats of one body and is processed with CNC digital controlled machinery.

The four pipe seats of the main frame have oiling function for greasing mission.

The rail of the side beam is made of imported linear sliding rail with higher accuracy and longer life span.

The main cutting body is a integrated one, 4 pipes up and down together with the cylinder, this 4 pipe must be conventric, we use CNC processing machine guarantee the convertric.

The magnetic scale and reading head can guarantee the cutting accuracy.

The table can turing 360 degree, and stop at 45 degree, 90 degree, 180 degree, 270 degree. And can 85 degree tilting

With steel leg and main motor with inverter

China

China

SHANGHAI CHEERSURE INTERNATIONAL TRADING COMPANY

Contact Supplier

Have a Question? Ask our expert

Questions & Answers on Stone Slab Cutting Machines in China

Can a water jet machine cut granite?

Posted by Visitor

![]() Reply to this question

Reply to this question

The high pressure water jet combined with the CNC cutting table is particularly useful for cutting stones such as marble and granite. Other materials that the waterjet cutter can cut include glass, ceramic tile and concrete bricks, etc.

Answered by StoneContact

Like

Which machine is used to cut Granite and Basalt?

Posted by Visitor

![]() Reply to this question

Reply to this question

The diamond blade circular saw can be used on most types of granite. The wet cut circular saw produces less dust during cutting, making it the best option for cutting granite tiles.

Answered by StoneContact

Like