If you need our help, we will be glad to help you until you find your products.

Skype: StoneContact.com

WhatsApp/Wechat: +86-17689946988

Type: Stone Factory MachinesStone Surface Processing Machines Water Blast Machine

FOB Price:$11500-12500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite

Machinery Function Features:

1YR

1YR

China

China

China Team Electric Co.,Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Handling, Loading MachinesAutomatic Loader, Unloader for Slabs

FOB Price:€4433-4433

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone

Machinery Function Features:

1YR

1YR

Viet Nam

Viet Nam

AARDWOLF INDUSTRIES

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

FOB Price:

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

3YR

3YR

Italy

Italy

Prussiani Engineering S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesSingle Arm Block Cutting Machine

FOB Price:$12000-17000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

14YR

14YR

China

China

Xiamen Asian Stone Imp.& Exp. Co.,Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesStone Waxing Machine

FOB Price:$11000-12000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Type: Stone Factory MachinesStone Block Cutting MachinesMulti Wire Saw Machine

$459999-469999

Warranty: 12 Months

Usage: Granite

Machinery Function Features:

10YR

10YR

China

China

Fujian Xiapu Zhongyuan Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$13500-15000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

$25000-30000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

7YR

7YR

China

China

XIAMEN EASTERN PEGASUS CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Tile Cutting MachinesHydraulic Stone Splitting Machine

$7800-8000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Basalt, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$60000-80000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Tile Cutting MachinesMulti-Blade Cross-Cutter,Trimming

$25000-28000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

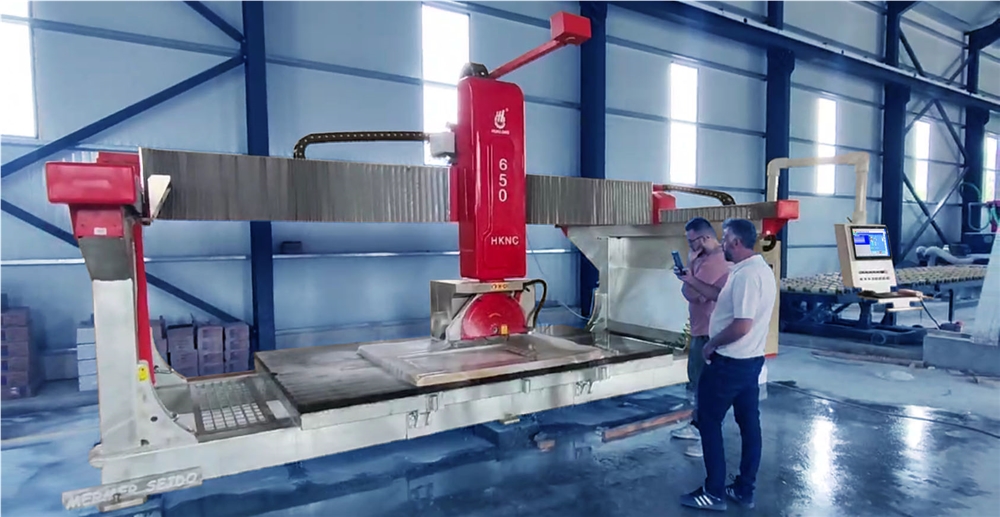

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$46500-49500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Hualong HKNC-550 5-Axis Bridge Saw is a high-precision CNC machine designed for advanced stone processing, featuring Italian ESA CNC system and Pegasus Zeus software. Ideal for kitchen countertops, vanity tops, and architectural stonework.

✅ Key Advantages:

✅ Applications:

Key Features:

🔹 5-Axis Interpolation

🔹 Smart Nesting

🔹 Heavy-Duty Construction

🔹 Optional Upgrades

Applications:

✔ Countertops & Vanities

- Kitchen sink cutouts | Undermount sink supports | Water groove milling

✔ Architectural Stone

- Straight/curved cladding panels | Stair tread profiling | Window sill cutting

✔ Artistic Work

- 3D relief engraving | Custom edge chamfering | Curved surface joining

📌 Technical Specifications

| Parameter | HKNC-550 |

| Max.blade diameter | 550mm |

| Max.cutting thickness | 150mm |

| C-axis Rotation accuracy | ±0.005°(RV reducer) |

| X/Y/Z axis positioning accuracy | ±0.01mm |

| Gross weight | 6500kg |

🔥 Limited Offer: Free 24K RPM spindle upgrade for first 10 orders ($5,000 value)

📞 Contact Now: +86-182-0602-1758

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Surface Processing Machines Slab Polishing Line Machine

$47500-82000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

$23261-46292

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Type: Stone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

$30000-35000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

CNC Wire saw machine is an automatic contouring machine, designed for cutting complex shapes.such as solid columns, hollow columns, large stone lines and English letters, etc .

Type: Stone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

$19600-22100

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

$24000-29500

Warranty: 12 Months

Usage: Granite, Marble, Limestone

Machinery Function Features:

Type: Stone Factory MachinesStone Handling, Loading MachinesJib Arm/U Type Container Loader

$1770-1860

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone

Machinery Function Features:

2YR

2YR

China

China

XIAMEN SPEEDONE INDUSTRY CO., LTD

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Quartzite, Sandstone, Travertine

Machinery Function Features:

8YR

8YR

Italy

Italy

Sassomeccanica S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesSingle Wire Block Squaring Machine

$37500-45000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite

Machinery Function Features:

1YR

1YR

China

China

XIAMEN XIANDA TRADING CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Surface Processing Machines Water Blast Machine

$3800-4000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Basalt

Machinery Function Features:

1YR

1YR

China

China

China Team Electric Co.,Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Handling, Loading MachinesAutomatic Loader, Unloader for Slabs

€3504-3504

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone

Machinery Function Features:

1YR

1YR

Viet Nam

Viet Nam

AARDWOLF INDUSTRIES

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

3YR

3YR

Italy

Italy

Prussiani Engineering S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$11000-16000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone

Machinery Function Features:

Type: Stone Factory MachinesStone Block Cutting MachinesMulti Wire Saw Machine

$555555-599999

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

10YR

10YR

China

China

Fujian Xiapu Zhongyuan Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesMulti Blade Automatic Slab Cutting Line

$15000-18000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesMulti Blade Gang Saw

$123000-157000

Warranty: 12 Months

Usage: Marble, Limestone, Sandstone

Machinery Function Features:

7YR

7YR

China

China

XIAMEN EASTERN PEGASUS CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesMulti Wire Saw Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Quartzite, Sandstone, Travertine

Machinery Function Features:

The latest triangle structure technology, higher cutting efficiency, and the stability of running. Designed by the man-machine intelligent system, convenience for operate, and has the full function of perfect production safety. Matching use Skystone multi-wire saw, with the high cutting quality, long life of wire, improve production efficiency and reduce comprehensive cost input. The machine has the advantages of low energy consumption, high versatility of accessories and low comprehensive cost of use and maintenance. The world's top after-sales service, rapid response to customer needs, to provide a complete set of customized cutting process production technical solutions.

6YR

6YR

China

China

FUJIAN SKYSTONE TECHNOLOGY CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$28500-32500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

This series of models are suitable for slab, tile, marble, artificial stone, granite, cement products and other building materials of special-shaped edge or multi-function cutting, is the most suitable for special-shaped cutting factory deep processing equipment.

This machine is a multi-functional intelligent CNC bridge stone cutting machine, operating system is my company in the import of five axis CNC on the basis of the development of their own, simple and easy to learn, to solve the problem that only high education to understand the use.

This machine can cut specifications board, at any Angle, any direction cutting, chamfering, cutting round, oval, horse’s belly edge shape, fan,polygons, form various shapes, such as the grid lines, lines, slash groove, contour lines and contour arc line, saw blades(and the workbench Angle) at any Angle between 0-90 degrees cutting, machinable column, column caps, flower POTS and other form. The machine head is equipped with milling cutter device (optional), when rotated to 0 degrees (milling cutter into 90 degrees), can be used as CNC machining center, on the stove, wash the basin hole, tap hole, guide sink, four sides of the milling and polishing(installed on the grinding wheel), straight line, curve, multi-level curve can be.

The machine adopts high-end water-cooled special motor, the speed is as high as 6000 RPM, the cutting speed is fast, the edge is smooth, neat, no edge collapse (Angle). The operation is simple and intuitive, set up intelligent fast, dumb touch interface, two or three data automatically generated graphics, a key to start the automatic processing. The fuselage adopts integral rigid welding structure, fastening and durable, convenient loading and shifting, and occupies a small area. Full servo motor drive, efficient, accurate, stable, and affordable (only the price of high-end ordinary infrared), is the market requirements continue to improve, the stone processing factory's good helper and profit generator!

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$60000-80000

Warranty: 12 Months

Usage: Granite, Marble, Slate, Quartzite

Machinery Function Features:

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesInfrared Bridge Cutting Machine

$22000-27000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

$37500-39000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$49500-52000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

The HKNC-650 5-Axis CNC Bridge Saw is a cutting-edge stone fabrication machine designed for precision cutting, complex 3D profiling, and automated processing of marble, granite, quartz, and ceramic slabs. With Italian ESA cnc system and Zues software, integrating photo slab, nesting and IoT-enabled real-time monitoring, it deliver 99.8% precision automation and maximizes material utilization and minimizes waste, aligning with the global trend of smart manufacturing.

Industrial-Grade Control: Italian ESA CNC system & Pegasus Zues dual-core platform with CE certification

1. 5-Axis Dynamic Control

2. Smart Material Handling:

3. AI-Optimized Efficiency

Productivity Upgrade Configuration (optional)

✓ Galvanized steel main frame with anti-corrosion design, extending equipment lifespan

✓ Rubber table surface suitable for different thickness materials, reducing cutting vibration by 40%

✓ Grating safety guard door enabling full-process production monitoring, compliant with CE safety standards

35+ Years Expertise | 100+ Countries Served for marble/granite processing solutions

CE-certified 5-axis CNC bridge saw with modular upgrades

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Tile Cutting MachinesMitre Saw, Edge Cutting Machine

$6000-10000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

$33000-38000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

CNC Wire saw machine is an automatic contouring machine, designed for cutting complex shapes.such as solid columns, hollow columns, large stone lines and English letters, etc .

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$13000-16600

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Four-axis bridge cuting machine is specially designed for stone special-shaped cutting, and precision cutting of countertop, it can process a variety of complex special-shaped, Simple operation, high intelligent automation, users only need to enter a few simple data, you can quickly finish the cutting of various size specifications of the table and edge strips, greatly saving labor, but also put an end to dust pollution, improve work efficiency and plate processing accuracy, it supports CAD graphics import, measuringinstrument.

Introduction To Functions:

1. Machine body with solid gantry girder, quenching heat treatment, guide rai, rack hole, all imported five-sided milling machine, fine milling, drilling, the precision is very high.

2.The paint of the whole machine, after many times of grinding, anti-rust treatment, many times of painting, effectively resist the corrosion of ground water, paint is more durable and less prone to peeling.

3.The cable of whole machine use CE standard, low temperature resistance, high folding resistance and long service life.

4. Electrical cabinet wiring is in accordance with the export of Europe and the United States international standard, assembly, anti-interference, all electrical parts are genuine brand.

5. Independently developed CNc system, user-friendly, simple operation, with multiple functions, and support free upgrade later.

6. 45 degrees miter, 85 degrees flip platform, using hydraulic cylinder control, stable and accurate.

7. Included computer with touch screen support, both mouse and keyboard can control, with wireless controller.

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

$24000-29500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Type: Stone Factory MachinesStone Handling, Loading MachinesJib Arm/U Type Container Loader

$2090-2390

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone

Machinery Function Features:

2YR

2YR

China

China

XIAMEN SPEEDONE INDUSTRY CO., LTD

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Quartzite, Sandstone, Travertine

Machinery Function Features:

8YR

8YR

Italy

Italy

Sassomeccanica S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesStone Carving,Engraving Machine

$20000-25000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Basalt, Sandstone

Machinery Function Features:

This machine adopts numerical control system, three-axis linkage, double row four-row slider, constand power spindle motor, two-way tool cooling system, with stable running, high precision and high efficiency advantages, suitable for processing marble, granite, bluestone, jade, agate, copper plate and aluminum plate and other materials.

1YR

1YR

China

China

XIAMEN XIANDA TRADING CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesSingle Wire Block Squaring Machine

$40000-50000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

The single-wire saw block square machine is specially designed for different stone trimming and thicker slab cutting, it adopts computer digital control, four-axis linkage, stable cutting, and has the automatic cycle function of moving vertical movement to cut and process slabs, automatic cutting board by board, it is an ideal equipment for mining, automatic cutting and squaring stone.

China

China

SHANGHAI CHEERSURE INTERNATIONAL TRADING COMPANY

Contact Supplier

Type: Stone Factory MachinesStone Surface Processing Machines Water Blast Machine

$3500-3550

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

350bar italy pump

1YR

1YR

China

China

China Team Electric Co.,Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesMulti Wire Saw Machine

$30000-40000

Warranty: 12 Months

Usage: Marble, Limestone

Machinery Function Features:

This series of products utilizes rollers to drive the diamond wire to move back and forth. Through the lifting of the workpiece to be processed, the diamond wire cuts the workpiece to achieve the purpose of processing. It is mainly used for the processing of slabs such as marble, artificial stone, graphite, refractory bricks, and composite materials. Compared with traditional stone processing equipment and tools, it can not only significantly reduce the cutting seam, decrease the stone powder generated during process- ing, increase the yield rate of materials, and reduce the thickness of the processed slabs to achieve translucency; but also reduce the noise during processing to below 100 dB, thus solving the "three highs" problems of high consumables, high noise, and high waste residue that hinder the intelligent manufacturing upgrade of the stone processing industry at one stroke.

The product is mainly composed of the following parts: transmission system, tensioning system, lifting system, wire routing system, spraying system, trolley traveling system [optional], etc. The equipment adopts a gantry structure, which has a stable structure and good guarantee of dimensional accuracy. The operating system has a friendly human-machine interface, with clear diagrams, simple operation, safety and reliability, and it also has the functions of real-time recording and data storage.

Higher Yield Rate High load-bearing capacity

The cutting seam can be as narrow as 0.4-0.6mm, resulting in a high effective yield rate.

Lower Energy Consumption

Saves water and electricity. Currently, their power consumption per square meter of processing is about 1.5-3 kWh [varies with different cutting materials), and the water consumption during processing is reduced by over 30% compared to traditional equipment.

Lower Waste Discharge

Compared to processing equipments that use gang saws, under the same production capacity, it can reduce wastewater discharge by over 30% and waste residue by over 50%.

Lower Noise

Compared to traditional stone processing equipments, it can reduce noise by about 35 decibels.

Higher Safety

The product has low cutting vibration during operation, does not pull the slabs, and eliminate the risk of injury from falling quarry stones.

Elevating Type

The cutting head is fixed, enabling higher operational cutting spead.

High Load-bearing capacity of the main shaft

Adopting a 5-bearing structure for the long spindle, it has a large support force span and stable force bearing.

The micron-level clearance fit between the support holes and the spindle ensures the steady state of dynamic balance during high-speed operation.

High-strength design of the pay-off and take-up reels

With a thick-walled and high-strength design, it can avoid the influence of the pay-off and take-up pressure on the accuracy of the wire reels after multiple wire winding operations, and prolong the service life of the wire reels and the stability of wire arrangement.

Unique system control

The multi-axis linkage control algorithm adopts high-precision control methods such as electronic cam and electronic gear.

The multi-axis load algorithm ensures the stability of the cutting wire mesh.

The PID control algorithm realizes the stability of the tension system.

China

China

Monte-Bianco Diamond Applications Co., Ltd

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

$78750-82500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Machine body with solid gantry girder, quenching heat treatment, guide rail, rack hole, all imported five.sided milling machine, fine milling, drilling, the precision is very high.

The paint of the whole machine, after many times of grinding, anti-rust treatment, many times of painting.effectively resist the corrosion of groundwater, Paint is more durable and less prone to peeling.

The cable of whole machine use CE standard, low temperature resistance, high folding resistance and long

service life.

Electrical cabinet wiring is in accordance with the export of Europe and the United States internationalstandard, assembly, anti-interference, all electrical parts are genuine brand.

Independently developed CNC system, user-friendly, simple operation, with multiple functions, and supportfree upgrade later.

45 degrees miter, 85 degrees flip platform, using hydraulic cylinder control, stable and accurate.

Included computer with touch screen support, both mouse and keyboard can control, with wireless controller.

5YR

5YR

China

China

XIAMEN SHUINAN MACHINE CO.,LTD.

Contact Supplier

Have a Question? Ask our expert

Tell Suppliers what you want to buy

Submitted successfully, thank you!