If you need our help, we will be glad to help you until you find your products.

Skype: StoneContact.com

WhatsApp/Wechat: +86-17689946988

Type: Stone Factory MachinesStone Slab Cutting MachinesCombined 5 Axis Saw & Waterjet Cutting

FOB Price:$85000-115000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

THE PERFECT MARRIAGE Combined 5 axis - bridge saw + Waterjet for ceramic, stone, marble and granite

HKNC-450J Sawjet is a 5 axis cnc cutting center with cutting-edge technology that combines the power of waterjets and the precision of diamond saws, which results in a high efficient cutting method that not only enhances accuracy but also significantly reduces material waste.

It's extremely veratile and suitable for processing a wide variety of items made of marble, granite, quartzite , ceramic , other natural and composite stone.

Two Technologies Together

It's a cnc machine optimises cutting operations with:

The machine can also perform milling operations thanks to the tool installed on the main motor shaft.

HKNC-450J sawjet, modular designed, is a five-axis beast tailored to your unique needs, maximizing productivity, and pushing the envelope of what's possilble.

Equipment Details:

Benefit:

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesStone Carving,Engraving Machine

FOB Price:$29000-29800

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

This 5 Axis 3D engraving machine features a high-performance design with advanced 5-axis linkage technology, equipped with high-performance servo motors and precision gearboxes to ensure high accuracy and stability in the engraving process. The machine is equipped with a ±90 degree pendulum head and ±360-degree rotary table, and combined with the RTCP 5-axis control system, it can realise multi-angle flexible processing. It is suitable for relief carving, artwork and other stone precision processing, is the ideal choice for high-end stone carving.

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

FOB Price:$29000-30500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5 Axis CNC Bridge Saw

The machine is an integrated five-axis bridge cutting machine, for the different specifications of the plateand a variety of special-shaped copying processing(such as polygon, triangle, fan, countertop, oval,diamond, circle, rim of horse's belly, chamfer at anyangle, special-shaped copying and engraving). lt has the advantages of fast speed, high cutting precision, simple and intelligent operation, suitable for cutting slab, marble, granite, quartz stone, and other stone processing. lt is the first choice of project and stone processing enterprises.

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

FOB Price:$23200-24100

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5 Axis CNC Bridge Saw

The machine is an integrated five-axis bridge cutting machine, for the different specifications of the plateand a variety of special-shaped copying processing(such as polygon, triangle, fan, countertop, oval,diamond, circle, rim of horse's belly, chamfer at anyangle, special-shaped copying and engraving). lt has the advantages of fast speed, high cutting precision, simple and intelligent operation, suitable for cutting slab, marble, granite, quartz stone, and other stone processing. lt is the first choice of project and stone processing enterprises.

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

FOB Price:

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Artificial Stone, Quartzite, Sandstone, Travertine

Machinery Function Features:

8YR

8YR

Italy

Italy

Sassomeccanica S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCombined 5 Axis Saw & Waterjet Cutting

$32000-32000

Warranty: 12 Months

Usage: Granite, Marble, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Advantages of this waterjet cutter

1. The smooth cutting quality is flawless.

2. Cutting precision reaches up to 0.1mm. Edge joints are uniform, and the water-cooled cutting system enables intricate jigsaw puzzles and murals.

3. Cutting speed is exceptionally fast, with outstanding product consistency and interchangeability.

4. Drilling, cutting, and forming can be performed simultaneously in a single operation.

5. Improves the work environment by reducing dust and noise exposure for operators.

6. Cold cutting process preserves material integrity without damaging internal structure.

7. Capable of processing composite materials and fragile ceramics.

8. Cutting tools handle metals, rubber, foam, plastics, composites, stone, ceramic tiles, marble, glass, and more.

Regarding dimensions, we offer 4000*2000mm, 3000*2000mm, 2000*1500mm, 2500*1500mm, 6000*2000mm, etc.

1YR

1YR

China

China

XIAMEN TYS MACHINE CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$48000-55000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5 Axis Bridge cutting machine adopt 5 Axis linkage CNC system Control, Bus-based absolute value servo(with memory function for power off). high-precision linear guide rail, ball screw transmission, oil-immersed track structure, with multi-function, high precision, strong stability and other advantages. Its processing functions include: arbitrary-shaped lines, fan-shaped plates, small space, and simpleoperation. It is a great equipment for stone processing.

1YR

1YR

China

China

XIAMEN XIANDA TRADING CO., LTD.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

$32000-38000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

14YR

14YR

China

China

Xiamen Asian Stone Imp.& Exp. Co.,Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$12900-20900

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$50000-80000

Warranty: 12 Months

Usage: Granite, Marble, Slate, Artificial Stone

Machinery Function Features:

Description The latest 5+1 CNC bridge saw machine can cut and trim granite, marble, artificial stone, slate and other stones at any angle and shape. The key parts of the machine are imported high-quality accessories, and the system adopts the ltalian ESA system, which has fast and stable operation. The corresponding servo and touch display are also the same brand as EsA. The system can also be customized with Blue Elephant customized system. Features 1. The A axis can automatically rotate 0-90°, while the C axis can rotate up to 360° 2. The slab can be positioned by taking photos, in addition, this machine can automatically plan the cutting path directly from the generated map, great)improving processing efficiency. 3. The overturned worktable is adopted, which has large overturning weight redundancy, up to 85°. 4. The ltalian servo motor is used to complete circular cutting, square cutting, fan cutting, oval cutting, 45" bevel cutting, drilling, outer edge polishing, etc.

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$12500-20100

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$13200-16500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Four-axis bridge cuting machine is specially designed for stone special-shaped cutting, and precision cutting of countertop, it can process a variety of complex special-shaped, Simple operation, high intelligent automation, users only need to enter a few simple data, you can quickly finish the cutting of various size specifications of the table and edge strips, greatly saving labor, but also put an end to dust pollution, improve work efficiency and plate processing accuracy, it supports CAD graphics import, measuringinstrument.

Introduction To Functions:

1. Machine body with solid gantry girder, quenching heat treatment, guide rai, rack hole, all imported five-sided milling machine, fine milling, drilling, the precision is very high.

2.The paint of the whole machine, after many times of grinding, anti-rust treatment, many times of painting, effectively resist the corrosion of ground water, paint is more durable and less prone to peeling.

3.The cable of whole machine use CE standard, low temperature resistance, high folding resistance and long service life.

4. Electrical cabinet wiring is in accordance with the export of Europe and the United States international standard, assembly, anti-interference, all electrical parts are genuine brand.

5. Independently developed CNc system, user-friendly, simple operation, with multiple functions, and support free upgrade later.

6. 45 degrees miter, 85 degrees flip platform, using hydraulic cylinder control, stable and accurate.

7. Included computer with touch screen support, both mouse and keyboard can control, with wireless controller.

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

$31900-33000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

AC 5-Axis Cutting Head: Unlimited rotation paired with China's first real-time height measurement technology—cut directly without scanning trajectories! Boosts waterjet efficiency with automatic curved surface cutting and ±75° cutting angle capability, ideal for high-angle stone slab joining processes.

Processing Capabilities: Monolithic stone sinks, countertops, island counters, dining tables, coffee tables, and various custom patterns.

1YR

1YR

China

China

XIAMEN TYS MACHINE CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$25000-39000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$43000-64000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Hualong HKNC-500+ is a 5/6 axis interpolated cutting and milling machine with Italian ESA cnc system, the latest in top bridge saw design, reliable and verstile, specifically for processing marble, granite, artifical quartz, other natural stones and ceramic, with speed and accuracy automates cutting (straight or shaped, vertical or inclined), 3D profiling, milling and drilling as the tasks requirement.

This stone cnc machine can be very customized, it is the best solution for fabshop with high productivity of:

Features:

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$15000-20000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Quartzite, Sandstone

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$40500-58500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

4YR

4YR

China

China

FUJIAN JOBORN MACHINERY CO.,LTD.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

8YR

8YR

Italy

Italy

Sassomeccanica S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$13500-16500

Warranty: 12 Months

Usage: Granite, Marble, Sandstone

Machinery Function Features:

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$46000-49000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

The HKNC-560 Plus is a high-precision, 5+1-axis synchronized CNC stone processing machine engineered for workshops seeking versatility, efficiency, and cost-effectiveness. Designed for cutting, shaping, and engraving natural/synthetic stone, ceramics, and composites, it integrates advanced Italian ESA CNC technology with user-centric features to streamline complex tasks like curved contour cutting, vertical/horizontal machining, and precision engraving.

5-Axis Precision Control

Enhanced Efficiency

User-Friendly Operation

Flexible Tooling

Advanced Optional Modules

Ideal for: Countertop fabrication, architectural stonework, and custom ceramic engraving.

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$13500-15000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

6YR

6YR

China

China

Quanzhou DAFON Machinery Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$60000-80000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$46500-49500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Hualong HKNC-550 5-Axis Bridge Saw is a high-precision CNC machine designed for advanced stone processing, featuring Italian ESA CNC system and Pegasus Zeus software. Ideal for kitchen countertops, vanity tops, and architectural stonework.

✅ Key Advantages:

✅ Applications:

Key Features:

🔹 5-Axis Interpolation

🔹 Smart Nesting

🔹 Heavy-Duty Construction

🔹 Optional Upgrades

Applications:

✔ Countertops & Vanities

- Kitchen sink cutouts | Undermount sink supports | Water groove milling

✔ Architectural Stone

- Straight/curved cladding panels | Stair tread profiling | Window sill cutting

✔ Artistic Work

- 3D relief engraving | Custom edge chamfering | Curved surface joining

📌 Technical Specifications

| Parameter | HKNC-550 |

| Max.blade diameter | 550mm |

| Max.cutting thickness | 150mm |

| C-axis Rotation accuracy | ±0.005°(RV reducer) |

| X/Y/Z axis positioning accuracy | ±0.01mm |

| Gross weight | 6500kg |

🔥 Limited Offer: Free 24K RPM spindle upgrade for first 10 orders ($5,000 value)

📞 Contact Now: +86-182-0602-1758

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$28500-32500

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

This series of models are suitable for slab, tile, marble, artificial stone, granite, cement products and other building materials of special-shaped edge or multi-function cutting, is the most suitable for special-shaped cutting factory deep processing equipment.

This machine is a multi-functional intelligent CNC bridge stone cutting machine, operating system is my company in the import of five axis CNC on the basis of the development of their own, simple and easy to learn, to solve the problem that only high education to understand the use.

This machine can cut specifications board, at any Angle, any direction cutting, chamfering, cutting round, oval, horse’s belly edge shape, fan,polygons, form various shapes, such as the grid lines, lines, slash groove, contour lines and contour arc line, saw blades(and the workbench Angle) at any Angle between 0-90 degrees cutting, machinable column, column caps, flower POTS and other form. The machine head is equipped with milling cutter device (optional), when rotated to 0 degrees (milling cutter into 90 degrees), can be used as CNC machining center, on the stove, wash the basin hole, tap hole, guide sink, four sides of the milling and polishing(installed on the grinding wheel), straight line, curve, multi-level curve can be.

The machine adopts high-end water-cooled special motor, the speed is as high as 6000 RPM, the cutting speed is fast, the edge is smooth, neat, no edge collapse (Angle). The operation is simple and intuitive, set up intelligent fast, dumb touch interface, two or three data automatically generated graphics, a key to start the automatic processing. The fuselage adopts integral rigid welding structure, fastening and durable, convenient loading and shifting, and occupies a small area. Full servo motor drive, efficient, accurate, stable, and affordable (only the price of high-end ordinary infrared), is the market requirements continue to improve, the stone processing factory's good helper and profit generator!

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$60000-80000

Warranty: 12 Months

Usage: Granite, Marble, Slate, Quartzite

Machinery Function Features:

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

$37500-39000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

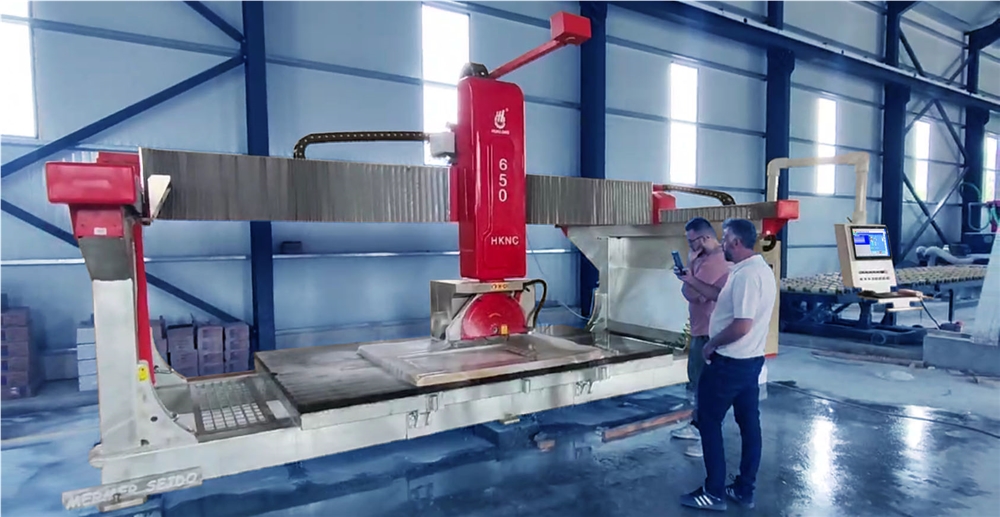

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$49500-52000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

The HKNC-650 5-Axis CNC Bridge Saw is a cutting-edge stone fabrication machine designed for precision cutting, complex 3D profiling, and automated processing of marble, granite, quartz, and ceramic slabs. With Italian ESA cnc system and Zues software, integrating photo slab, nesting and IoT-enabled real-time monitoring, it deliver 99.8% precision automation and maximizes material utilization and minimizes waste, aligning with the global trend of smart manufacturing.

Industrial-Grade Control: Italian ESA CNC system & Pegasus Zues dual-core platform with CE certification

1. 5-Axis Dynamic Control

2. Smart Material Handling:

3. AI-Optimized Efficiency

Productivity Upgrade Configuration (optional)

✓ Galvanized steel main frame with anti-corrosion design, extending equipment lifespan

✓ Rubber table surface suitable for different thickness materials, reducing cutting vibration by 40%

✓ Grating safety guard door enabling full-process production monitoring, compliant with CE safety standards

35+ Years Expertise | 100+ Countries Served for marble/granite processing solutions

CE-certified 5-axis CNC bridge saw with modular upgrades

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$13000-16600

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Four-axis bridge cuting machine is specially designed for stone special-shaped cutting, and precision cutting of countertop, it can process a variety of complex special-shaped, Simple operation, high intelligent automation, users only need to enter a few simple data, you can quickly finish the cutting of various size specifications of the table and edge strips, greatly saving labor, but also put an end to dust pollution, improve work efficiency and plate processing accuracy, it supports CAD graphics import, measuringinstrument.

Introduction To Functions:

1. Machine body with solid gantry girder, quenching heat treatment, guide rai, rack hole, all imported five-sided milling machine, fine milling, drilling, the precision is very high.

2.The paint of the whole machine, after many times of grinding, anti-rust treatment, many times of painting, effectively resist the corrosion of ground water, paint is more durable and less prone to peeling.

3.The cable of whole machine use CE standard, low temperature resistance, high folding resistance and long service life.

4. Electrical cabinet wiring is in accordance with the export of Europe and the United States international standard, assembly, anti-interference, all electrical parts are genuine brand.

5. Independently developed CNc system, user-friendly, simple operation, with multiple functions, and support free upgrade later.

6. 45 degrees miter, 85 degrees flip platform, using hydraulic cylinder control, stable and accurate.

7. Included computer with touch screen support, both mouse and keyboard can control, with wireless controller.

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$60000-80000

Warranty: 12 Months

Usage: Granite, Marble, Quartzite

Machinery Function Features:

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Travertine

Machinery Function Features:

8YR

8YR

Italy

Italy

Sassomeccanica S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

3YR

3YR

Italy

Italy

Prussiani Engineering S.p.A.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$25000-30000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$45000-50000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5 Axis CNC Bridge Saw

The machine is an integrated five-axis bridge cutting machine Ik-3050, it is much more big than IK 3520 and it's customized. Five-axis bridge cutting machine is for the different specifications of the plateand a variety of special-shaped copying processing(such as polygon, triangle, fan, countertop, oval,diamond, circle, rim of horse's belly, chamfer at anyangle, special-shaped copying and engraving). lt has the advantages of fast speed, high cutting precision, simple and intelligent operation, suitable for cutting slab, marble, granite, quartz stone, and other stone processing. lt is the first choice of project and stone processing enterprises.

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesMulti Blade Automatic Slab Cutting Line

$42000-44000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone

Machinery Function Features:

The machine adopts advanced PLC intelligent control system to realize fully automatic control. High-efficiency stone cutting equipment with reasonable structure, reliable operation, high processing precision and high automation degree. Independent transverse beam with active frequency conversion adjustment can meet a variety of cutting requirements.

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$30000-40000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Artificial Stone, Quartzite

Machinery Function Features:

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$38000-41000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

Hualong HKNC-450 5-Axis CNC Bridge Saw - Integrating Italian ESA control system with 35 years of Chinese manufacturing expertise, designed for global stone fabricators to achieve precision & profitability. From mass production to custom countertops, HKNC delivers ±0.02mm repeatability and modular scalability for quality-cost balance.

Core Advantages:

✅ ESA CNC System (Italy) - Dynamic vibration compensation for ±0.1mm contour accuracy - Power failure recovery & cloud-based parameter backup

✅ Human-Machine Collaboration - Canon EOS 1300D camera assists manual defect marking with 18MP clarity - Drag-and-drop nesting interface improves planning efficiency by 50%

✅ Localized Manufacturing Edge - CE-certified components + 48hr technical support

✅ 6 Customizable Upgrades Optional Modules:

Global Applications:

🔥 2025 Global Launch Offer

- First 10 orders receive Free CAD Toolkit (10 int'l countertop templates)

- Bonus ESA Remote Diagnostic Service ($2,500 value)

📞 Call +86-182-0602-1758 for multilingual technical proposals

3YR

3YR

China

China

Fujian Province Hualong Machinery Co.,Ltd

Contact Supplier

Type:

$30000-40000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Quartzite, Sandstone, Travertine

Machinery Function Features:

5YR

5YR

China

China

Blue Elephant CNC Machinery

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$23000-24000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5 Axis CNC Bridge Saw

The machine is an integrated five-axis bridge cutting machine, for the different specifications of the plateand a variety of special-shaped copying processing(such as polygon, triangle, fan, countertop, oval,diamond, circle, rim of horse's belly, chamfer at anyangle, special-shaped copying and engraving). lt has the advantages of fast speed, high cutting precision, simple and intelligent operation, suitable for cutting slab, marble, granite, quartz stone, and other stone processing. lt is the first choice of project and stone processing enterprises.

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCombined 5 Axis Saw & Waterjet Cutting

$36000-37000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

In five axis CNC system, coordination of X, while Y, Z and A, B of the two axis of rotation, the water jet cutting head can swing in any direction. When cutting, the computer according to the real-time calculation of the density and thickness of materials by cutting the workpiece, and control the cutting head along the cutting path and operation, to achieve three-dimensional complex shape of the workpiece cutting, such as surface slope cutting, chamfering and cutting high precision conical surface circular surface complex. The water jet and achieve higher performance and bring better benefits.

Cutting edge

1 strong versatility, almost all materials can be cut.

The 2 is cold water jet cutting, cutting does not produce thermal effects, no deformation, no residue, no ablation, does not change the physical and chemical properties of materials.

3 small slot, with the characteristics of cooling cutting, can improve the utilization rate of materials.

4 cutting medium only water and natural abrasives, cutting process does not produce other substances, is clean and environmentally friendly cutting process.

5 after cutting, the cutting surface is smooth and smooth, not in the cutting process of cutting objects have any damage, you can play a lot of cutting tools can not achieve the cutting operation.

The scope of application of water jet is very wide, from the metal material to non-metallic materials, materials from natural to artificial materials, from food to household goods, basically can be cut, "universal cutting machine" reputation.

Main application areas are:

1, ceramics, stone and other building materials processing

2, the processing of glass products, such as glass parts cutting, building decoration, craft glass

3, machinery industry, metal plate cutting

4, the advertising industry signs, art pattern cutting

4YR

4YR

China

China

Quanzhou Xinhaineng Machinery Co,. Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

$29000-38000

Warranty: 12 Months

Usage: Granite, Marble, Sandstone, Travertine

Machinery Function Features:

3YR

3YR

China

China

Quanzhou Dafon Time Technology Co., Ltd.

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

$31900-33000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

AC 5-Axis Cutting Head: Unlimited rotation paired with China's first real-time height measurement technology—cut directly without scanning trajectories! Boosts waterjet efficiency with automatic curved surface cutting and ±75° cutting angle capability, ideal for high-angle stone slab joining processes.

Processing Capabilities: Monolithic stone sinks, countertops, island counters, dining tables, coffee tables, and various custom patterns.

1YR

1YR

China

China

XIAMEN TYS MACHINE CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

$23200-24100

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

5 Axis CNC Bridge Saw

The machine is an integrated five-axis bridge cutting machine, for the different specifications of the plateand a variety of special-shaped copying processing(such as polygon, triangle, fan, countertop, oval,diamond, circle, rim of horse's belly, chamfer at anyangle, special-shaped copying and engraving). lt has the advantages of fast speed, high cutting precision, simple and intelligent operation, suitable for cutting slab, marble, granite, quartz stone, and other stone processing. lt is the first choice of project and stone processing enterprises.

1YR

1YR

China

China

JINAN IKCNC TECHNOLOGY CO.,LTD

Contact Supplier

Type: Stone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Onyx, Quartzite, Sandstone, Travertine

Machinery Function Features:

Spain

Spain

INSEMAC TECHNOLOGY SL

Contact Supplier

Type: Stone Factory MachinesStone Slab Cutting MachinesCombined 5 Axis Saw & Waterjet Cutting

$38000-46000

Warranty: 12 Months

Usage: Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features:

1.High Efficiency & Energy saving Intensifier Unit:

Exclusive patented Energy-saving &High efficiency Intensifier assembly(Patent No. : ZL 2017 2 1116875. 3) ;

Power: 22KW,220V/380V/415V/480V,50Hz/60Hz; Max Pressure : 450MPa, Working Pressure :≤340MPa; Max Water flow:3.7L/MIN

Dual Cooling mode: Air Cooling & Water Cooling; Oil Pressurized ratio: 1:27;

German Schneider electrical components

2.CNC Controller System:

Industrial PC ,with 19-inch industrial display,Industrial controller, Windows 10 operation system ;

Shanghai Weihong professional waterjet CNC Control system

Shanghai Weihong special waterjet cutting software,the listed company product, advanced and reliable, easy to lear

3.CNC Cuting Table:

Gantry Structure, the water tank adopts 16mm plate and double- layer keel structure

X Axis Cutting stroke:3000mm/ 4000mm ;Y Axis Cutting stroke: 2000mm; Z Axis Cutting stroke: 100mm

Repeat positioning accuracy: ±0. 01mm; Cutting accuracy: ± 0.1mm;Rapid Position Speed: 10m/min

X, Y and Z Axis control mode:Shanghai CNC (Weihong) bus servo control system

Vertical and Horizontal beams are welded with H-shaped structure steel and reinforcement bars structure;

oil - immersed guide wire rod with dust protection structure; Imported TBI brand ball screw and guide rail

4.AC 5Axis Cutting Head:

rol Axis : 5Axis |

A Axis Rotation : ±75 ° |

C Axis Rotation: Infinite Rotation |

Angle control accuracy: ±0.01 |

Equipped with Weihong laser measured height device

Probe system and Carema system are optional,which can generate the basin cutting path automatically .

5. Auto Sand Supply System

550IBS capacity ,can supply sand for 10hours continuous working

Air compressor of 0. 2MPa is required,power is not less than 3kw.

China

China

Foshan Nengbo Machinery Co.,Ltd

Contact Supplier

Have a Question? Ask our expert

Tell Suppliers what you want to buy

Submitted successfully, thank you!